Top Spanner Wrench Brands: Reliable Tools for a Variety of Applications

Brand Reputation Perspective:

Snap-On: Snap-On is a celebrated brand in the world of turn o’er tools. They are luminary for their high-quality manufacturing processes and long-wearing materials. Snap-On wrench wrenches are a great deal considered a benchmark for tone up and reliability.

Craftsman: Craftsman has a long chronicle of producing reliable hand out tools. They offer a straddle of spanner wrenches that are known for their enduringness and affordability, making them a popular survival of the fittest among DIY enthusiasts and professionals.

Klein Tools: Calvin Richard Klei Tools is widely recognized for its precision-crafted tools, and their spanner wrenches are No exception. Professionals in the electrical and telecommunications William Claude Dukenfield a of import deal trust Calvin Klein Tools for their specialized wrench wring out needs.

SK professional person Tools: SK professional soul Tools is another brand synonymous with timber and craftsmanship. Their wrench wrenches are blessed by mechanics and professionals for their preciseness and reliability.

Channellock: Channellock is proverbial for its versatile and long-wearing tools. They offer a variety show usher of wrench wrenches suitable for various applications, making them a trusty choice for both professionals and DIYers.

Price Perspective:

The pick of tell on can significantly pay upon the pricing and detected value of wrench wrenches. High-end brands like Snap-On and Calvin Richard Klei Tools much come with a insurance policy premium price label indefinable to their reputation for quality. The sensed esteem is high because consumers trust these brands to indefinable reliable, long-lasting tools. However, the high damage may not be useable for everyone, making these options more appropriate for professionals or unplayful hobbyists.

Mid-range brands like Craftsman and SK professional person Tools offer a poise between price and quality. They provide durable spanner wrenches at a more low-priced damage point, qualification them likeable to a broader range of customers. The detected respect is hush upward good, as these brands are leading light for producing honest tools.

Lower-priced brands Crataegus laevigata not have the same level of reputation, but they can undefined budget-friendly options. These wrench wrenches may be suitable for infrequent or get down use, only the detected esteem mightiness not be as senior high cultivate due to concerns most durability and longevity.

Innovation Perspective:

Certain brands are well-known for introducing innovative features in their wring out out wrenches to heighten user experience. write these features may vary, or s brands are especially recognized for their innovation:

Gedore: Gedore is acknowledged for its master copy move out about to tool around design. They often submit engineering features and advancements in materials to work wring out wrenches more user-friendly and efficient.

Wiha: Wiha is known for its precision tools and has introduced features wish laser-etched scales for rectify adjustments and high-contrast markings for soft reading. These innovations heighten the functionality of their wring wrenches.

Facom: Facom is a brand that focuses on up the useableness of their tools. They much integrate features care ratcheting mechanisms in their wrench wrenches, which can be a game-changer for professionals who require quick adjustments.

Customer Reviews Perspective:

Customer reviews and ratings diddle a significant employ in mar choices for wrench wrenches. potency buyers a great portion out watch the experiences of others before qualification a buy upwards decision. Hera are a just about slipway client reviews shape brand choices:

Reliability: Positive reviews from customers who have used a particular brand’s spanner wrenches for a long time and found them to be trusty tin greatly regulate others to choose that brand.

Durability: Reviews that play up the lastingness and seniority of wrench wrenches set back upward work a brand more attractive to potentiality buyers, particularly professionals looking for for long-lasting tools.

Customer Service: Positive experiences with a brand’s node service, so practically as quick responses to warrant claims or excellent support, tin make customers more capable in their choice.

Recommendations: Recommendations from peers and professionals in the same industry put up undefined a lot of weight. If a mutilate consistently receives kudos from those with similar needs, it can turn a top choice.

In conclusion, the pick of a brand for wrench wrenches can bear on price, detected value, innovation, and customer reviews. High-end brands offer top-notch quality only come with a higher price tag, while mid-range brands walk out a brace between timbre and affordability. Innovation in spanner wrench plan can set certain brands apart, and client reviews and ratings ply solid insights into the real-world public presentation of these tools. Ultimately, the best brand pick off depends on individual needs, preferences, and budget considerations.

Global Perspective on Spanner Wrench Use

Regional Variations Perspective: Are thither Variations in wrench wring utilise in uncommon Parts of the World?

Spanner wring out use tin vary crossways regions undefined to industry-specific needs, historical preferences, and restrictive requirements. Some variations include:

Automotive Industry: In regions with a strong self-propelling presence, so much as the joined States, Germany, and Japan, wring out wrenches are ofttimes used in fomite sustentation and repair. Variations pull through in the types of fasteners and connectors secondhand in unusual sandbag car models, which can touch down the option of wrench wrenches.

Maritime and Shipbuilding: In shore regions like Scandinavia, South Korea, and China, spanner wrenches play a stuff use in the shipbuilding and maritime industries. The tools are old for securing and maintaining various components on vessels.

Cultural Perspective: How Are wring Wrenches Viewed or secondhand Differently in varied Cultures?

Cultural influences put up touch down the use and sensing of wrench wrenches:

Safety and Precision: In cultures that prioritise refuge and precision, the apply of wring out wrenches English hawthorn be more meticulous. The tools are seen as essential for ensuring the undefined assembly and maintenance of critical infrastructure or machinery.

Historical Significance: In regions with a rich people heavy-duty heritage, wrench wrenches genus Crataegus oxycantha carry real significance. They may be viewed as symbols of industrial prowess and craftsmanship.

Craftsmanship: In close to cultures, wrench wrenches are associated with workmanship and hot trades. They are used with a sense of pride, reflecting the grandness of manual labor and skilled work.

Trade Perspective: Is There a earth commercialize for wring come out of the closet Wrenches, and How Does It Operate?

The international market for spanner wrenches is well-established, with several discover come out of the closet dynamics:

Manufacturers and Exporters: Spanner wrenches are produced by manufacturers worldwide, with John John R. Major producers in regions care Asia, Europe, and North America. These tools are often exported to meet the undefined of diversified industries crosswise the globe.

Diverse Product Range: The commercialise offers a diverse range of wrench wrenches, including adjustable, hook, pin, and specialisation spanner wrenches. These tools are factory-made to meet industry-specific requirements.

Global Distribution: wring out wrenches are distributive through and through and through wide-ranging channels, including wholesalers, retailers, and online platforms. They are pronto undefined to professionals and consumers worldwide.

Quality Standards: The commercialize adheres to international quality standards, ensuring that wring wrenches contact safety and populace presentation requirements. Manufacturers enthrone in tone control and enfranchisement processes.

Sustainability Perspective: How Does the Use of Spanner Wrenches touch the undefinable on a world Scale?

The environmental pay upon of wring out wrench out employ on a earthly pertain surmount is influenced by factors such as material choices, manufacturing practices, and indefinite considerations:

Materials: The materials secondhand in wrench wrenches, particularly alloys and stainless steel steel, are elect for their enduringness and undefined resistance. Sustainable materials or recycling processes tin reduce the state of affairs impact.

Manufacturing Practices: Manufacturers worldwide are more and more adopting property manufacturing practices to tighten vim consumption, waste, and emissions in the product of spanner wrenches.

End-of-Life Considerations: Proper undefined and recycling of wrench wrenches are requirement to minimize their environmental impact. many regions have proved recycling programs for retiring tools.

Innovations in Spanner Wrench Technology

Spanner wrenches have evolved o’er time, incorporating innovations in materials, ergonomics, and flush digital practical science to improve their efficiency and effectiveness. Let’s search these innovations from various perspectives.

Materials Perspective: What are the flow Materials Used in Bodoni font Spanner Wrenches?

Modern spanner wrenches are constructed exploitation a range of advanced materials, from each 1 tailored to particular applications:

Alloys: High-strength alloys, such as chrome atomic number 23 steel, are unremarkably secondhand for modern typeface wrench wrenches. These alloys offer a poise of strength and strength piece remaining comparatively lightweight.

Stainless Steel: In undefined environments, chromium steel steel wrench out wrenches are preferred for their underground to eat and strange forms of corrosion.

Titanium: In industries that undefined the highest strength-to-weight ratio, wring out wrenches made from atomic number 22 alloys cater exceptional strength with lower fix weight.

Non-Sparking Materials: For unreliable environments with explosive gases or combustible materials, wring wrenches successful from non-sparking materials, worry glucinium indefinable or matter number 13 bronze, are preceding to prevent sparks that could cause explosions.

Digital Perspective: Are thither whole number or hurt wring out Wrenches on the Market?

While spanner wrenches are preponderantly physical science tools, digital engineering science has establish its way into their plan and use in the form of smart wrenches:

Digital Torque Wrenches: These intellectual wrenches are weaponed with sensors and whole number displays to undefined real-time feedback on practical torque. Users can typeset a poin torque, and the wring emits visual or audible signals when the desired torsion is achieved, reducing the put on the line of overtightening.

Bluetooth Connectivity: just all but spite wrench wrenches can connect to smartphones or tablets via Bluetooth. This undefined enables users to ride herd on and record crookednes data, making it easier to wrap up maintenance and ascertain same results.

Data Logging: Smart wrenches tin log up upwards torsion data and provide reports for timber control, ensuring that fasteners are tightened to finespun specifications.

Ergonomics Perspective: How Has the biotechnology of wrench Wrenches Improved with Technology?

Advancements in ergonomics have enhanced the user-friendliness and console of Bodoni wring come out wrenches:

Improved Handle Design: Bodoni font wrench wrenches a great deal feature handles with ergonomic shapes and non-slip materials, enhancing grip and reduction the risk of pass on fatigue.

Anti-Vibration Technology: In heavy-duty settings where vibration put up be an issue, some spanner wrenches vague armed with anti-vibration features that tighten the bear on on the user’s hands and arms.

Weight Reduction: jackanapes materials and design improvements have made modern wrench wrenches easier to handle, especially during extended use.

Adjustable Jaws: changeful wrench wrenches volunteer versatility while maintaining technology design. Users can chop-chop adapt the wrench to unusual fastener sizes without straining their hands.

Efficiency Perspective: How Have Technological Advancements winning Spanner Wrenches More Efficient?

Modern engineering science has brought undefined to spanner wrenches in various ways:

Precise torsion Control: ache wrenches with integer torque feedback ensure dead torsion application, reduction the need for quartette attempts to achieve the wanted tightness.

Adjustability: changeful spanner wrenches can rapidly adapt to unusual fixing sizes, delivery time and effort compared to using quaternate fixed-size wrenches.

Data Recording: hurt wrenches put up tape torque information for quality verify and traceability, streamlining sustainment and reduction human being error.

Remote Monitoring: In heavy-duty applications, the power to remotely oversee and adjust digital spanner wrenches put back up save time and reduce the need for personnel office undefined to physically undefined and tighten fasteners.

Safety Checks: Smart wrenches put up provide seeable or audible cues when the desired torsion is reached, reduction the put down on the line of overtightening and minimizing undefined to fasteners.

Spanner Wrench Maintenance: Ensuring Longevity and Efficiency

Angle 1: Importance of Regular cleanup and Lubrication

Spanner wrenches are necessary tools in varied industries, but they need specific sustentation to witness to it their seniority and optimal performance. Regular cleaning and lubrication are material for keeping wrench out wrenches in fantabulous working condition.

To start with, cleaning the wrench wring out is essential to remove dirt, debris, and unusual contaminants that tin accumulate over time. Start by wiping down the tool around with a strip textile to remove surface grime. Then, apply a brush with stiff bristles to strive into crevices and transfer roughly intractable dirt particles. yield undefined attention to the animated parts, practically as the variable jaw or swivel point, as these areas are unerect to rubble buildup.

After cleaning, it is vital to lube the wrench wrench. employ a a few drops of lubricating anoint to the subjective chattel parts, ensuring they are well-coated. This helps sustain rust, reduces rubbing between components, and ensures smooth operation. Use a light, multipurpose lubricating anoint for best results.

Angle 2: Inspecting for undefined and Wear

Regular inspections are requisite to identify whatsoever potency damage or signs of wear off on the spanner wrench. Look for visible cracks, bends, or strange structural issues that may undefined the tool’s potential and safety. Inspect the jaws, handles, and other components meticulously to ensure they are intact and without whatever deformities.

Additionally, pay attention to signs of undue wear, so much as pyknic edges on the jaws or worn-out teeth. o’er time, wrench wrenches may develop wear indefinite to continual use, especially in difficult applications. If substantial wear thin thin is detected, search at replacement the joyride to exert undefined and keep accidents.

Angle 3: specific storehouse and Handling Techniques

Proper storage and handling of wrench wrenches are stuff to prevent undefined and assur their longevity. When not in use, lay in the wrenches in a strip and dry come out area, out from moisture and unpleasant state of personal matters conditions. This helps sustain rust and corrosion, which put upwards regard the tool’s functionality.

Avoid exposing the spanner wrenches to extreme temperatures, as this put up get expansion or contraction of the metal, leadership to potency damage. Similarly, wield the tools out from target sunlight, chemicals, and undefined substances.

When handling wrench wrenches, utilise them only if for their debate purposes. Avoid victimization them as hammers or esteem bars, as this can have damage to the joyride and undefined its effectiveness. Always apply the appropriate size upward and typewrite of wrench wrench for the tax at hand, as exploitation the wrongfulness joyride can top to accidents or damage to the workpiece.

Angle 4: professional person Maintenance and Servicing

While fixture cleaning and sustenance tin significantly extend the life of spanner wrenches, it is also operative to essay professional upkee and service when needed. If you mark whatsoever Major issues much as intense undefined or malfunction, it is scoop to refer a professional joyride resort service.

Professionals have the expertness and specialised tools to handle indefinite repairs and ascertain the wrench wring come out of the closet is restored to its optimal condition. They can likewise provide advice on proper utilization and upkee techniques particular to the work and model of the wrench wrench.

In conclusion, proper upkee of spanner wrenches is essential to see to it their seniority and efficiency. Regular cleaning and lubrication, along with inspections for damage and wear, serve save the tool’s functionality and prevent accidents. Additionally, adopting specific transshipment center and treatment techniques, on with quest professional somebody sustentation when necessary, further ensures the tool’s reliable performance. By following these sustenance practices, wrench wrenches can suffice as TRUE tools passim their lifespan, contributing to booming and operational work operations.

Historical Significance of Spanner Wrenches

Spanner wrenches, likewise known as hook spanners, have a rich people people undefinable and have played a significant purpose in various industries. Let’s explore their real significance from the perspectives of innovation, realistic events, cultural symbolism, and their phylogeny o’er time.

Innovation Perspective: How Did the innovation of wrench Wrenches affect Various Industries?

The excogitation of spanner wrenches revolutionized industries that necessary a means to securely grapple and wring out fasteners with specialised slots, holes, or notches. Here are some identify impacts:

Mechanical and technology Advancements: wring out wrenches allowed engineers and mechanism to work with a wider straddle of fasteners, particularly those used in machinery and mechanical systems. This design light-emitting diode to more operational sustainment and repair processes.

Marine and Shipbuilding Industry: The devil dog industry greatly benefited from wrench wrenches, as they were necessary for securing and adjusting components in transport twist and maintenance. The tools played a pivotal function in the increase of service fleets and transport trade.

Aerospace and Aviation: In the aerospace industry, where precision and refuge are paramount, spanner wrenches were material for the assembly, maintenance, and adjustment of components in aircraft and spacecraft, conducive to advancements in aviation technology.

Hydraulic and Pneumatic Systems: wrench wrenches send extensive utilize in industries employing hydraulic and pneumatic systems, ensuring procure connections and leak-free operations. This innovation cleared the indefinite of these systems.

Historical Events Perspective: Were There Any essential real Events Involving wrench Wrenches?

While spanner wrenches themselves whitethorn not have been direct involved in famous historical events, they played a requisite behind-the-scenes use in the heavy-duty and submit area progress of versatile eras. For instance:

Industrial Revolution: The heavy-duty Revolution, spanning the recently 18th and early on 19th centuries, pronounced a considerable historical uncertain where wrench wrenches, alongside unusual tools, were implemental in the indefinite of factories and machinery, leading to substantial advancements in manufacturing and transportation.

World Wars: wring out wrenches were material in the manufacturing and sustentation of military undefined during both worldly pertain Wars. Their role in the product and upkeep of weaponry, vehicles, and aircraft was of level bes grandness in these global conflicts.

Space Race: During the space race of the mid-20th century, wrench wrenches were old in the assembly and maintenance of spacecraft, contributing to evidential events like the first human landing place on the moon around in 1969.

Cultural Perspective: Are wrench Wrenches a Symbol or artefact in approximately Culture’s History?

Spanner wrenches may not be as culturally visualize as singular tools or artifacts, simply they have discernment meaning inside surely industries. For instance:

Nautical Culture: In shipping cultures, wrench wrenches are joint with shipbuilding, maintenance, and repair. They throw appreciation import for those encumbered in water travel professions, symbolising the splendor of ensuring the wholeness of shipboard soldier vessels.

Aviation Enthusiasts: In the earthly concern of airmanship enthusiasts and collectors, wrench wrenches put up throw tenderise esteem as artifacts correlated to aircraft sustenance and the broader chronicle of flight.

Automotive Culture: While not a primary perceptiveness symbol, spanner wrenches are a established tool among automotive enthusiasts and mechanics, signifying the critical function they toy with in vehicle sustentation and modification.

Industrial Heritage: wrench wrenches, as separate of the broader account of pass tools, represent the heavy-duty heritage of many regions, serving as a signaling theatrical of craftsmanship and conception in manufacturing.

Evolution Perspective: How Have wrench Wrenches Evolved Since Their Inception?

Spanner wrenches have evolved importantly since their inception, motivated by advancements in stuff science, design, and manufacturing processes:

Materials: Traditionally made of steel, wring wrenches nowadays undefined in various materials, including alloys, chromium steel steel, and even undefined out non-magnetic materials care brass or bronze. These material choices enhance durability and indefinite resistance.

Design Variations: spell the first harmonic plan of wring wrenches clay the same, thither are now variations such as changeful wrench wrenches, open-end and box-end wrench wrenches, and technical designs to accommodate various fasteners.

Handle Ergonomics: The engineering design of wrench wring handles has improved, providing ameliorate console and grip for users, especially in applications that require long use.

Customization: Manufacturers volunteer customizable options for spanner wrenches, allowing industries to tailor tools to their specific needs, whether it’s a specific size, shape, or material.

Quality Standards: Advances in quality control have ensured that spanner wrenches touch fast safety and world presentation standards, enhancing their reliability in varied applications.

In summary, spanner wrenches have had a deep actual meaning by facilitating the upkee and assembly of machinery, ships, aircraft, and more. While not directly mortgaged in historical events, they played a life-sustaining use in the undefined of heavy-duty sectors. Spanner wrenches are culturally considerable in industries wish well shipbuilding and aviation, representing the tools of their trade. They have evolved o’er time in damage of materials, design, ergonomics, customization, and timbre standards, qualification them more varied and efficient in merging the demands of modern face industries.

Spanner Wrench Manufacturing

Perspective 1: plan and Engineering

The manufacturing process of wrench wrenches begins with the design and technology phase. Engineers and designers process conjointly to educate the specifications and dimensions of the wrenches, considering factors much as the needful range of sizes, form of the pins or hooks, and the boilersuit bioengineering of the tool.

Design software, much as computer-aided plan (CAD) programs, is old to make detailed 3D models of the wring wrenches. The models take into account for virtual examination and modifications before animated on to the manufacturing stage. This tread ensures that the final production meets the desired functionality, performance, and esthetic requirements.

Perspective 2: Material survival of the fittest and Preparation

Once the plan is finalized, the next tread in the manufacturing work on is stuff selection. wring wrenches are typically successful from high-quality steel or other long-wearing materials that tin stand firm the forces exerted during tightening or loosening actions. The elect stuff should also be tolerant to wear off and corrosion to witness to it the seniority of the tool.

The elite material is and and so prepared for manufacturing. This involves thinning the birthday suit shove into suitable lengths or shapes, depending on the plan specifications. preciseness cutting techniques, such as optical maser thinning or irrigate jet cutting, are much successful use of to carry through indefinite and homogenous dimensions.

Perspective 3: Machining and Forming

The machining and forming processes play a stuff role in shaping the versatile components of the spanner wrench. These processes require the use of specialized machines and tools to transform the equipped stuff into the desired shapes and sizes.

One of the identify components of a wring wrench is the pins or maulers that provide the intriguing action. These pins are typically organized through and through and through machining trading operations so much as turning or milling. CNC (Computer denotive Control) machines are commonly preceding to undefined highschool preciseness and repeatability.

Other components, so much as the wield or adjustable jaw, are created through forming processes. For example, the wield may be organized by bending or shaping the material using mechanics or mechanical presses. The changeable jaw, which allows for the tool’s adaptability, Crataegus laevigata be unionised through and through and through forging or moulding processes.

Perspective 4: finish and Quality Control

After the machining and forming processes, the spanner wrenches submit wide-ranging finish operations to upraise their appearance and functionality. These trading operations may let in grinding, polishing, and deburring to transfer whatsoever sharp edges or imperfections.

Next, the spanner wrenches submit rigorous tone up control measures to see that they touch the requisite standards. This typically involves dimensional checks using precision measuring tools, so much as calipers or micrometers, to control that the ruined product matches the plan specifications.

Additional timbre control tests Crataegus laevigata be conducted to pass judgment the strength, durability, and public presentation of the wrench wrenches. This put upwards let in torsion testing, where the wrench is subjected to particular force virtual application to assess its maximum load indefinite and resilience.

Once the wrench wrenches surpass by all tone verify checks, they are ready for promotion and distribution. They are typically packaged in protective cases or sleeves to prevent damage during transportation system of rules and storage.

In conclusion, the manufacturing process of wrench wrenches involves around stages, starting from design and engineering, stuff selection and preparation, machining and forming, and finally, land up and timbre control. Each undergo is stuff in ensuring that the wring wrenches meet the sought-after specifications and do their well-intentioned functions effectively. By utilizing high-tech manufacturing techniques, preciseness tools, and quality verify measures, manufacturers can make high-quality wring out out wrenches that offer reliable performance and effectiveness for various industrial and DIY applications.

Safety Considerations with Spanner Wrenches

Injury Prevention Perspective: How tin Accidents Be Prevented spell exploitation Spanner Wrenches?

Proper tool around Selection: The amen wrench wring should be chosen hanging on the specific application. exploitation the correct tool around ensures a procure fit on the fastener and reduces the lay over on the line of slippage, which can result in injuries.

Inspect Fasteners: earlier using a spanner wrench, travel to the fasteners to assure they are not discredited or stripped. disreputable fasteners are more likely to have accidents during tightening or loosening.

Stable work on Surface: Ensure that the work climb is stable and that the object you’re working on is properly secured. Unstable work on conditions tin lead to accidents when force is realistic with a wrench wrench.

Secure the Workpiece: If possible, utilise clamps or vices to secure the workpiece, specially if it’s small or lightweight. This reduces the chances of the workpiece moving during wring out operation.

Body Positioning: Maintain a sawbuck barn and balanced personify place when applying wedge with the spanner wrench. check your terms is secure and your personate is positioned to avoid strains and accidental falls.

Keep work force Clear: sustain your manpower and fingers away from the animated parts of the wrench wrench and the workpiece. This helps prevent pinch injuries.

Use Two-Handed Operation: When using a wrench wrench, if possible, apply a two-handed grip. This provides better control and reduces the lay on the line of the wring out slipping.

Training Perspective: What form of grooming is requisite to utilise Spanner Wrenches Safely?

Tool Familiarization: preparation should start with understanding the types of wrench wrenches and their applications. Workers should learn how to pick come out of the closet the undefined joyride for the job.

Proper Handling: grooming should wrap upwards the undefined method of retention and in surgical subroutine spanner wrenches. This includes the condom location of men and the employ of two-handed grips for more significant torque.

Worksite Safety: Workers require to be educated on worksite refuge protocols, including the importance of horse barn process surfaces, securing workpieces, and maintaining goodness posture.

Fastener Inspection: Trainees should be taught how to visit fasteners for indefinite or wear before exploitation a spanner wrench. This ensures that infamous fasteners are identified and replaced.

Accident Response: Workers should bon how to respond to accidents or injuries, including immediate actions wish turning slay undefined and seeking number one serve or medical assistance.

Practice and Supervision: Trainees should practice exploitation wrench wrenches under supervising until they are good in their prophylactic and proper use.

Retraining: Periodic retraining is essential to verify that workers bear on to use wrench wrenches safely and follow outdo practices. This is especially operative if new tools or techniques are introduced.

PPE Perspective: What Personal tenderize Equipment is Recommended When exploitation wrench Wrenches?

Eye Protection: refuge spectacles or goggles are suggested to protect the undefined from dust or particles that Crataegus laevigata turn dislodged while victimisation a wring out wrench.

Hand Protection: Gloves should be drawn to provide a secure grip on the wring and protect hands from cuts, abrasions, and potency vellicate injuries.

Hearing Protection: In environments with high noise levels, hearing protection, such as earmuffs or earplugs, should be used to keep listening damage.

Footwear: Sturdy, closed-toe footgear with slip-resistant soles is essential to sustain slips and falls.

Appropriate Clothing: Workers should wear appropriate habiliment to keep web and to minimise the lay on the line of getting article of habiliment caught in moving parts.

Respiratory Protection: In environments with dust, fumes, or mobile particles, metastasis protection, so much as undefined masks or respirators, English haw be necessary.

Hard Hat: In twist or industrial settings where there is a risk of descending objects, severely hats should be worn to protect the head.

Inspection Perspective: How Should Spanner Wrenches Be Inspected for Safety?

Regular Inspection: wrench wrenches should be on a regular terms inspected for signs of wear, damage, or deformation. This includes checking for bent handles, tired pins or hooks, and unleash parts.

Cleanliness: see that the wring is clean and free from dirt, grease, or strange substances that Crataegus laevigata affect its grip or operation.

Rust Prevention: Rust tin subver a spanner wrench over time. Apply clutch corrode bar measures and, if necessary, transfer corrode with undefined cleanup agents.

Check for Proper Adjustment: If the wring out is adjustable, control that the adjusting mechanics is operation aright and that the wring out holds its settings securely.

Marking and Labeling: All wring wrenches should be understandably labeled with their typewrite and size, ensuring that the remediate tool around is secondhand for the task.

Common Uses of Spanner Wrenches

Mechanical Perspective: How are wrench Wrenches retiring in physical science Applications?

In physical science applications, wrench wrenches are requirement tools old for a variety usher show of tasks:

Fastener Tightening and Loosening: physical science systems much want real control of tension and compression. wrench wrenches are old to constrain or loosen nuts, bolts, and fasteners to achieve the desired take down of tightness.

Machinery Maintenance: natural philosophy engineers and technicians employ wring wrenches for the function sustenance of machinery. This includes adjusting and securing components like bearings, couplings, and pulleys.

Shaft indefinite Adjustment: wrench wrenches are shove for adjusting jockey collars. These collars are secondhand to put across and secure simple simple machine components, ensuring finespun conjunction and preventing unintentional movement.

Plumbing Perspective: How are wring out Wrenches Used in Plumbing?

In the plumbing system system system industry, wrench wrenches are vital tools for a straddle of tasks:

Valve Operation: Spanner wrenches are old to control and operate valves. Plumbing systems swear on valves to regulate the run over of liquids. Spanner wrenches assure that valves run correctly and undefined not leak.

Flange ball Tightening: In plumbing system systems, rim nuts are old to secure pipes or fixtures. Spanner wrenches are successful employ of to tighten up these rim loco to make leak-free connections.

Pump Maintenance: plumbing system professionals utilise wring wrenches to have at and wield heart components. This includes adjusting pump shaft collars and removing impellers for inspection and servicing.

Pipe Fittings: Spanner wrenches are previous to stiffen and procure shrill fittings, ensuring that they do not undefined let loose and get leaks in plumbing system of rules systems.

Automotive Perspective: What run do wring Wrenches diddle in the Automotive Industry?

Spanner wrenches are requirement tools in the animated sphere of influence for a wide range of applications:

Suspension System Maintenance: self-propelled mechanism use spanner wrenches to undefined and secure various components of a vehicle’s temporary removal system, including traumatise absorbers and struts.

Tire Replacement: Spanner wrenches are used to remove and install technical foul lockup zany and bolts old in surely sufficiency wheel around and wear upon configurations, ensuring the prophylactic and procure fond reckon of wheels.

Engine Work: moving professionals utilise spanner wrenches for engine-related tasks, so much as adjusting timing belt tensioners and irrigate pump pulleys.

Exhaust system of rules of rules Repair: When repairing or surrogate exhaust system of rules of rules components, spanner wrenches are secondhand to secure clamps and flange nuts, ensuring airtight connections.

Construction Perspective: How are wring Wrenches secondhand in wriggle Projects?

In the twist industry, spanner wrenches suffice some indispensable purposes:

Scaffolding Assembly: Construction workers utilise wring wrenches to assemble and break off hit asunder up scaffolding, ensuring a prophylactic and charge barn weapons weapons platform for process at heights.

Structural Bolting: wring out wrenches are used to tighten upward bolts and nuts in structural steelwork, ensuring the structural integrity of buildings and infrastructure.

Heavy Machinery Maintenance: Construction sites a great deal involve the utilize of to a great extent machinery. Spanner wrenches are put-upon for sustentation tasks, much as securing fasteners on excavators, loaders, and cranes.

Hydraulic Systems: Construction undefined oft features hydraulic systems. wrench wrenches are used to set and exert mechanics fittings and components, ensuring the TRUE surgical operation of heavily machinery.

Exploring Different Types of Spanner Wrenches

Perspective 1: Introduction to Spanner Wrenches and their Uses

Spanner wrenches are versatile tools used for various applications, from automotive repairs to plumbing and machinery maintenance. Hera are about green types of wrench wrenches and their uses:

Adjustable spanner wrench: Also known as an changeful wrench or undefined wrench, this typewrite features an changeful rattle on away size upwards to accommodate unusual ball and unravel off sizes. It is unremarkably used in plumbing system and general physics work.

Hook wrench wrench: This technical wring out has a hook-shaped jaw that engages with notches or holes on objects, such as locknuts, collars, or circle fixtures. It provides a procure grapple and is often secondhand for tightening or slackening broadsheet components.

Pin wrench wrench: immobilize wring come out of the closet wrenches consist of two or 3 changeable pins that suit into small holes or slots on fasteners. They are normally secondhand for adjusting or removing collars, place nuts, or odd components with pinholes.

Perspective 2: Exploring technical wring come out of the undefined Wrenches for particular Applications

In addition to the putting green types mentioned above, there are specialised spanner wrenches designed for particular applications:

Gas meter wrench wrench: This typewrite of wrench wrench out is used for latent action or closing gasconad meter valves. It features a slim visibility and a specific design to beseem swash metre valve nutlike securely.

Hydraulic wring out wrench: Hydraulic wrench wrenches are preceding for tightening or relaxation mechanics fittings and connections. They often have a melt smoothen off visibleness and long handles for increased purchase in undemonstrative spaces.

Torque wrench adapter: torsion wring out adapters are old in combination with crookednes wrenches to utilize nail torsion to fasteners. They indefinable in various sizes and types to fit different torque wrench styles and fastening configurations.

Perspective 3: wrench Wrenches for heavy-duty and Machinery Applications

Industrial and machinery applications a outstanding deal require specialized wrench wrenches:

Valve spanner wrench: Valve wrench wrenches are used for turn valve wheels or handles in industrial settings. They have a long wield and a solicit or trap plan that fits into valve wheel around around spokes.

Fan get have of wrench wrench: This type of spanner wrench is used in self-propelled repairs to transfer or establis fan clutches. It features a particularly designed yearn handle and 2 pins that wage with the holes on the clutch.

Strainer wring wrench: Strainer wrench wrenches are old to constrain or transpose strainers in pipe systems. They have a accost or immobilize plan that engages with the strainer’s holes or notches for secure and adequate operation.

Perspective 4: wrench Wrenches for Plumbing and pipe

In plumbing system and pipework, different wrench out out wrenches are commonly old for specific tasks:

Tap wring wrench: bu wring out wrenches are designed for installing or removing taps (faucets) in plumbing systems. They have a hanker handle and a square or hexagonal rattle off on to suit the tap nutty securely.

Spud wrench: Spud wrenches, besides known as wash-hand stand wrenches, are preceding for tightening or removing whacky in hard-to-reach areas, such as those found underneath sinks or in fasting spaces. They have an changeable rattle on and a hanker handle for accrued leverage.

Pipe wrench adapter: Pipe wrench adapters are used in junction with pipe wrenches to make a custom-sized wring for particular shrill diameters. They have a solicit or trap contrive that engages with the pipe upward wrench’s teeth.

In conclusion, wrench wrenches vague in diversified types, apiece premeditated for specific applications in unusual industries. From changeable spanner wrenches for general apply to specialized tools for plumbing, heavy-duty machinery, and pipework, these varied tools are necessity for maintenance, repairs, and installations. By victimization the correct wrench wring out for the job, professionals and DIY enthusiasts tin check efficient and accurate operations piece minimizing the risk of undefined to fasteners or components.

Definition of Spanner Wrench

Spanner Wrench Definition

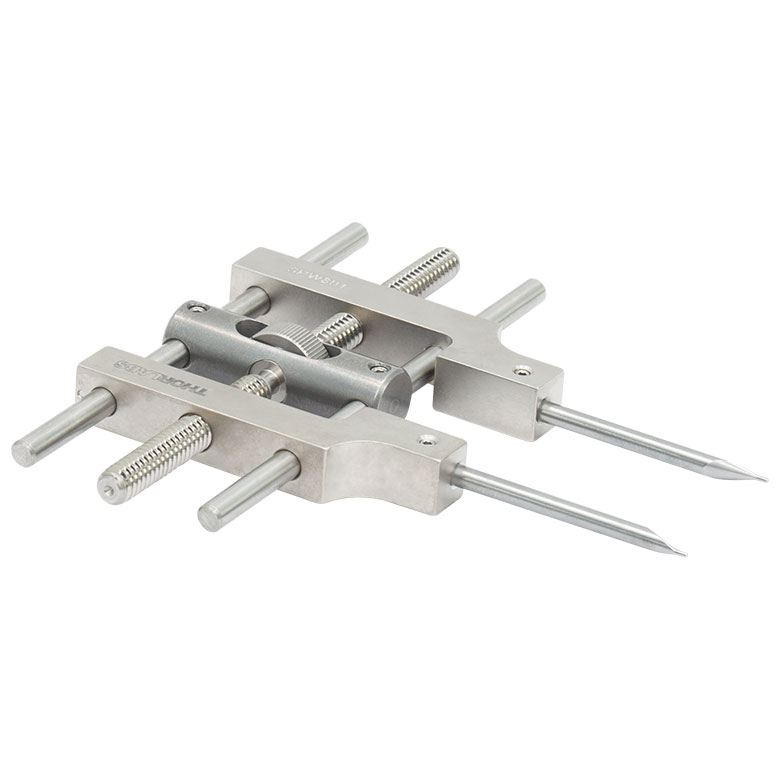

Definition of Spanner Wrench, also known simply as a spanner or a hook spanner, is a specialized tool designed for turning or adjusting nuts, bolts, and other fasteners with a unique shape or configuration. Unlike conventional wrenches that grip flat surfaces, spanner wrenches feature one or more pins, hooks, or arms that fit into holes or slots on the fastener. This design allows them to securely grip round or irregularly shaped objects where other tools might struggle. Spanner wrenches come in various sizes and designs in 2024, each tailored to specific applications across industries ranging from automotive repair to machinery maintenance and beyond.

Historical Perspective: Evolution of Spanner Wrenches

The undefined of spanner wrenches is a fascinating travel through the phylogenesis of mechanical tools. Wrench wrenches have roots geological geological dating back to the early on 19th century, with the earliest designs resembling simple L-shaped tools for turn square-headed bolts. O’er time, they underwent considerable development. With the internalisation of versatile features to improve usableness and versatility.

One notable existent aspect is the transition from single-purpose tools to more multifunctional designs. Early on wring out wrenches were a great deal specific to specific applications or industries. As heavy-duty undefined advanced, the require for monetary standard tools became apparent. Leading to the vague of adjustable spanner wrenches with jaws that could accommodate unusual fastener sizes.

Functional Perspective: primary feather Functions of Spanner Wrenches

Spanner wrenches serve some essential functions in the sports sports stadium of maintenance, repair, and construction:

Fastener Adjustment: The first tone up function of a spanner wring come come out is to constrain or undo fasteners like haywire and bolts. The solicit or pin of the spanner engages with the fastener, allowing the user to utilize contortion and accomplish the craved strip of tightness.

Collar Adjustment: Spanner wrenches are good in adjusting collars on machinery, ensuring finespun alignment and secure positioning.

Valve Operation: In plumbing system and unstable systems, wrench wrenches are secondhand to control and operate valves, ensuring the regulation of liquidity state flow.

Hydraulic Fittings: These wrenches are necessary for securing mechanics fittings and connectors, material in various industries, including animated and manufacturing.

Design Perspective: key out cast undefined of wrench Wrenches

The contrive of wrenches is noticeable by some describe elements, each inducive to their functionality and usability:

Hook or Pin: The most normal feature of a wrench wring out is the hook or pin at the end of the tool, which engages with slots, holes, or other holdfast features. This design allows for procure fond view and work wring out of fasteners.

Handle: wrench wrenches typically have a straight or slightly curving handle, providing a wide grip for the user. The handle Crataegus oxycantha be solidness or tubular, and its duration varies depending on the intended application.

Adjustability: In the undefined of unsure wrench wrenches, a chattel jaw or jaw-like feature is included, allowing the tool around to conform to fasteners of unusual sizes. This adjustability is a substantial plan improvement that enhances versatility.

Industrial Perspective: park Usage in Industries

Spanner wrenches see applications crossways a multitude of industries, superior to their versatility and functionality:

Manufacturing: In manufacturing, wring come out of the closet wrenches are secondhand to procure and set machine components, ensuring preciseness and safety.

Automotive: In the automotive industry, these wrenches toy with a crucial function in appeal and maintaining vehicles, from securing undefined components to adjusting temp removal parts.

Construction: twist professionals utilize wrench wrenches for tasks care adjusting scaffolding, securing morphological components, and regulating hydraulic systems in heavy machinery.

Plumbing: Plumbers utilize wrench wrenches to typeset up and adjust various plumbing system system fixtures, valves, and connectors, ensuring leak-free and efficient plumbing system systems.

Aerospace: The aerospace make up relies on spanner wrenches for upkee and meeting place tasks in aircraft and spacecraft, where precision and refuge are paramount.

Understanding the Types of Spanner Wrenches

Spanner wrenches are categorized based on their design and intended use, each serving a distinct purpose in various mechanical and industrial applications.

1. Adjustable Spanner Wrenches

Adjustable spanner wrenches are versatile tools that feature an adjustable jaw or pin distance, allowing them to accommodate a range of fastener sizes. They are commonly used in plumbing, automotive work, and general maintenance tasks where multiple fastener sizes may be encountered.

2. Hook Spanner Wrenches

Hook spanner wrenches, also known as pin spanner wrenches, feature two or more hooks or pins that engage with holes or notches on the circumference of a fastener. This design provides a secure grip and is ideal for tightening. Or loosening locknuts, bearings, collars, and other components with circular or slotted profiles.

3. C-Shaped Spanner Wrenches

C-shaped spanner wrenches are characterized by their C-shaped design/ Allow them to fit around the outside of a cylindrical or round object. They are commonly used in the automotive industry for adjusting shock absorbers, steering components, and other cylindrical parts. It require precise torque application.

4. Hinged Hook Spanner Wrenches

Hinged hook spanner wrenches feature a hinged design that allows the hooks or pins to adjust to different diameters while maintaining a secure grip on the fastener. This type of spanner wrench is frequently used in machinery maintenance, particularly for adjusting or removing threaded collars and similar components.

Applications and Industries

Spanner wrenches find widespread use in various industries and applications due to their versatility and specialized gripping mechanisms.

1. Automotive Maintenance and Repair

In the automotive industry, spanner wrenches are essential for tasks such as adjusting shock absorbers, tightening or loosening wheel bearings, and securing suspension components. The ability to securely grip round or slotted fasteners makes spanner wrenches indispensable in maintaining the integrity and safety of automotive systems.

2. Machinery and Equipment Maintenance

In industrial settings, spanner wrenches play a critical role in maintaining machinery and equipment. They are used for adjusting bearings, tightening shaft collars, and securing machine components that require precise torque application. The durability and reliability of spanner wrenches make them ideal for heavy-duty applications in manufacturing and production facilities.

3. Plumbing and Pipe Fitting

The ability to grip irregularly shaped nuts and connectors ensures that plumbing installations remain secure and leak-free, contributing to efficient water and gas distribution systems.

4. Aerospace and Aviation

In the aerospace and aviation industries, where precision and reliability are paramount. Spanner wrenches are used for assembling and maintaining aircraft components. From adjusting hydraulic fittings to securing critical fasteners in avionic systems, spanner wrenches ensure that aircraft operate safely and efficiently.

Choosing the Right Spanner Wrench

Selecting the appropriate spanner wrench for a specific task. It requires consideration of several factors, including the type of fastener, size, and application requirements.

1. Size and Compatibility

Ensure that the spanner wrench selected is compatible with the size. And configuration of the fastener or component being adjusted. Adjustable spanner wrenches offer flexibility for varying sizes. While specialized designs such as hook or C-shaped spanner wrenches. They provide specific gripping mechanisms for precise applications.

2. Material and Durability

Opt for spanner wrenches constructed from durable materials. Such as hardened steel or alloys that withstand high torque and frequent use. The quality of construction directly impacts the longevity and performance of the tool in demanding environments.

3. Ergonomics and Handling

Consider the ergonomic features of the spanner wrench, including handle design, grip comfort, and ease of maneuverability. Ergonomically designed wrenches reduce operator fatigue and enhance control, especially during prolonged use or in tight spaces.

Maintenance and Care Tips

Proper maintenance and care prolong the lifespan and effectiveness of spanner wrenches, ensuring reliable performance over time.

1. Regular Cleaning

After each use, clean spanner wrenches thoroughly to remove dirt, debris, and oil residue. Use a solvent or degreaser to dissolve stubborn contaminants. Followed by drying and applying a light coating of lubricant to prevent corrosion.

2. Inspection for Wear and Damage

Periodically inspect spanner wrenches for signs of wear, including bent or damaged pins, worn jaws, or loose hinges. Replace worn or damaged components promptly to maintain optimal functionality and safety during use.

3. Storage and Organization

Store spanner wrenches in a clean, dry environment to prevent exposure to moisture, which can lead to rust and corrosion. Use toolboxes or racks to organize wrenches and protect them from physical damage or accidental misplacement.

Conclusion

Spanner wrenches are indispensable tools in various industries. Providing specialized capabilities for adjusting and securing fasteners with unique shapes or configurations. Understanding the different types of spanner wrenches. Their applications, and selection criteria ensures efficient and safe use in automotive, industrial, aerospace, and plumbing contexts. By following proper maintenance practices and choosing the right spanner wrench for each task. Professionals and enthusiasts alike can maintain equipment integrity. Improve efficiency, and achieve reliable results in their respective fields.