The function and usage of T track stopper

T-slot miter rail jig is a very practical tool for woodworking, which can effectively improve the accuracy and efficiency of woodworking. In the following, we will introduce in detail what The Stopper does and how to use it.

What the T Track Stopper does?

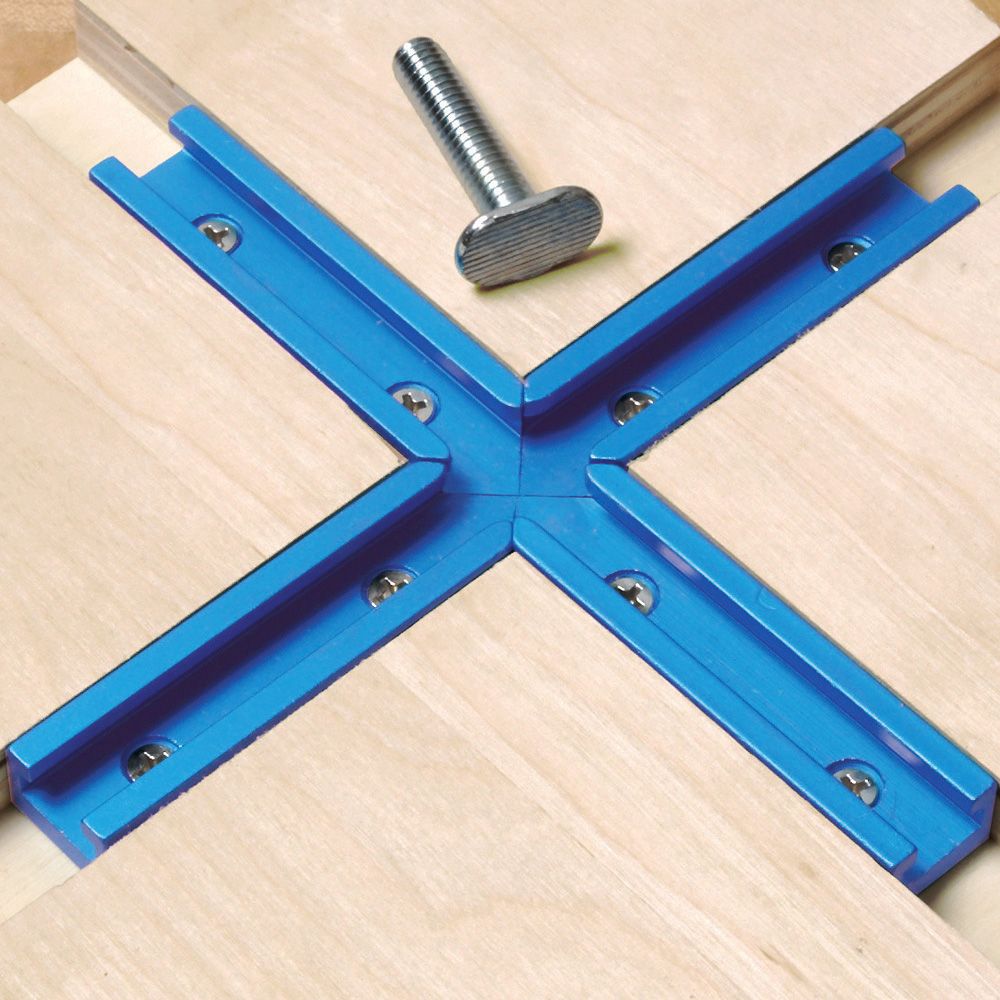

T-slot miter rail jig is a positioning device for T-track, which improves machining accuracy and efficiency by fixing and positioning items. It usually consists of stoppers and T-track fittings to keep items in place and secure during processing. The The Stopper is very convenient to use, you only need to install it on the T-shaped track, adjust the position of the stopper and the control of the handle, and you can precisely position and fix the items.

Here are the main functions of The Stopper:

- Stability and reliability: T-slot miter rail jig can stably fix wooden products on the T-shaped track without shifting or shaking, thus ensuring the processing quality.

- Precision and accuracy: The T Track Stopper allow for fine adjustments, maintaining precision and accuracy in woodwork.

- Efficiency and Convenience: The T Track Stopper is easy to install, adjust and easy to use, increasing machining efficiency and convenience.

How to use T Track Stopper?

The use of T Track Stopper is very simple, just follow the steps below.

- Determining T-Track Position: First you need to determine the T-Track position in order to properly install the T Track Stopper.

- Installing the T-slot miter rail jig: Install the Stopper on the T-track, which usually needs to be tightened to ensure its stability.

- Adjusting stop position: Adjust the The Stopper’s stop position as needed to ensure woodwork can be precisely positioned and secured.

- Adjusting the Handle Control: Adjust the handle control to make sure the stopper secures the woodwork.

- Secure Woodwork: Place woodwork on the T-slot miter rail jig and use the handle controls to secure it to it.

- Processing: Once the wood product is secured on the T Track Stopper, the processor can begin processing.

It should be noted that when using The Stopper, you need to choose the appropriate specification and model according to the specific wood products and processing projects, and follow the instructions for proper installation and fixing. At the same time, you need to pay attention to safety issues to avoid hand injuries or equipment damage.

Material of T track stopper

- Aluminum Alloy: Aluminum alloy is a lightweight, strong, corrosion-resistant material commonly used to manufacture the body of T-rail fittings.

- Plastic: Plastic is a lightweight, wear-resistant, and corrosion-resistant material that is commonly used in the manufacture of connecting and holding parts for T-track fittings.

Advantages of T Track Stopper

The material of the Stopper has the following advantages:

- Lightweight: The main body and accessories of T-slot miter rail jig are usually made of aluminum alloy or plastic, which is light in weight and easy to carry and use.

- Strong corrosion resistance: The main body and accessories of T Track Stopper usually have excellent corrosion resistance and can be used in harsh environments such as humidity and high temperature.

- Good mechanical properties: The main body and accessories of Stopper usually have excellent mechanical properties, which can withstand large forces and vibrations to ensure processing quality and efficiency.

- Good Durability: The body and accessories of the T-slot miter rail jig are generally very durable and can be used for a long time without damage.

In conclusion, the material of The Stopper has the advantages of light weight, corrosion resistance, good mechanical properties and durability, which can improve processing efficiency and accuracy. When using The Stopper, you need to choose the appropriate specification and model according to the specific processing project and wood product, and follow the instructions for proper installation and fixing.

All in all, T-slot miter rail jig is a very practical woodworking tool, which can improve the accuracy and efficiency of woodworking. When using, just follow the above steps to operate.

Improve workpiece machining efficiency with T track stopper

The Stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. In this article, we will focus on how to use T-slot miter rail jig to improve workpiece processing efficiency, hoping to help your woodworking work.

Advantages of the T Track Stopper

The Stopper is a very practical woodworking tool, it has the following advantages:

- Improve machining accuracy: T-slot miter rail jig can ensure the precise positioning and fixing of workpieces, thereby improving machining accuracy and effectively reducing machining errors.

- Improve processing efficiency: The Stopper can quickly fix the workpiece, avoiding the tedious process of manual adjustment, and improving processing efficiency.

- Enhanced safety: T Track Stopper can stably fix the workpiece, avoiding the workpiece from sliding or tilting during machining, enhancing safety.

- Wide range of application: T-slot miter rail jig can be applied to various processing projects, including cutting, drilling, grooving and so on.

How to Improve Workpiece Machining Efficiency Using T Track Stopper?

- Preparations: Before starting to use the Stopper, preparations are required: confirm the size of the T-shaped track and the size of the workpiece to be used, and select the appropriate T-slot miter rail jig. Install the T-track and The Stopper, and prepare the required processing tools on the workbench.

- Determine the workpiece position: place the workpiece to be processed on the workbench, and fix the workpiece on the T-shaped track by adjusting the position and handle control of the T Track Stopper. Make sure that the position of the workpiece is correct and stable.

- Perform machining operations: By using machining tools, perform required machining operations such as drilling, cutting, etc.

- Adjust the position of the T-slot miter rail jig: When a new machining operation is required on the workpiece, the position of the Stopper needs to be adjusted to ensure that the workpiece can be positioned and fixed accurately.

- Check the processing quality: After the processing is completed, it is necessary to check the processing quality to ensure that the workpiece meets the requirements.

Precautions

When using T Track Stopper, you need to pay attention to the following:

- Choose the appropriate T-slot miter rail jig size and model.

- When installing The Stopper and T-shaped track, you need to strictly follow the instructions to ensure correct and firm installation.

- During processing, it is necessary to ensure that the positions of the workpiece and the Stopper are correct and stable.

- After the processing is completed, it is necessary to check the processing quality to ensure that the workpiece meets the requirements.

How to install T track stopper?

T Track Stopper is a positioning device for T-track, which can improve machining accuracy and efficiency by fixing and positioning items. When using the Stopper, the correct installation method is very important to ensure the stability and safety of the T-slot miter rail jig.

Prepare before use:

Before installing The Stopper, you need to make the following preparations:

- Confirm the size and workpiece size to be used, and select the appropriate Stopper.

- Cut the to the required length and clean up the debris in the track.

- Prepare the required installation tools, such as screwdrivers, wrenches, etc.

All in all, T-slot miter rail jig is a very practical tool for woodworking, which can improve machining accuracy and efficiency. When using The Stopper to improve workpiece processing efficiency, it is necessary to select the appropriate specification and model and operate in strict accordance with the instructions. By using the Stopper correctly, the workpiece processing efficiency can be improved, the processing safety can be enhanced, and the processing quality can be improved.

T track stopper: a good helper for woodworking

T-slot miter rail jig is a positioning device for T-track, which can improve machining accuracy and efficiency by fixing and positioning items. The Stoppers typically consist of a stopper and T-track fitting to keep items in place and secure during processing. However, different job projects and woodwork require different sizes of T Track Stoppers to suit their needs. This article will introduce the size specifications of the T-slot miter rail jig, hoping to help you choose the right size and model.

Dimensions of the T Track Stopper

- The Stopper Width

The width of the T-slot miter rail jig is a very important specification, which determines which size T-track the T Track Stopper can fit. Usually, the width of T Track Stopper has the following specifications:

- 1/4″: Suitable for 1/4″ wide T-track.

- 5/16″: Suitable for 5/16″ wide T-track.

- 3/8″: Suitable for 3/8″ wide T-track.

- 1/2″: Suitable for 1/2″ wide T-track.

- 3/4″: Suitable for 3/4″ wide T-track.

- T-slot miter rail jig Height

The Stopper is usually fixed in height and can be adapted to different wood products. At present, there are mainly the following height specifications on the market:

- 1/2 inch: suitable for most processing projects.

- 1 inch: suitable for processing taller wood products.

- 1.5 inches: Suitable for very tall woodwork processing projects.

- Length of T Track Stopper

The length of the T-slot miter rail jig is also an important specification as it determines what length of woodwork the T Track Stopper can hold. There are mainly the following length specifications on the market:

- 2 inches: suitable for shorter wooden products.

- 3 inches: suitable for wood products of general length.

- 4 inches: suitable for longer wooden products.

- 6 inches: suitable for very long wooden products.

How to choose a suitable T Track Stopper?

To choose a suitable T-slot miter rail jig, you need to choose according to the specific wood products and processing projects. Here are a few important selection factors:

- The width of the. The width of the T Track Stopper needs to be selected according to the width of the to ensure that it can be properly installed and secured on the track.

- The height of the woodwork. The height of the Stopper needs to be selected according to the height of the woodwork to ensure that the woodwork will fit properly on the T-slot miter rail jig.

- The length of the woodwork. The length of the Stopper needs to be chosen according to the length of the woodwork to ensure that the Stopper can hold the full length of the woodwork.

- Processing project needs. It is necessary to choose the specifications and models of the T-slot miter rail jig according to the needs of the processing project. For example, when it is necessary to perform operations such as curve cutting and inner concave-convex, it is necessary to choose a the Stopper with higher precision and more flexibility.

Material of T track stopper

- Aluminum alloy: Aluminum alloy is a lightweight, strong, corrosion-resistant material that is commonly used to manufacture the body and handle of the stopper.

- Stainless Steel: Stainless steel is a high-quality metallic material that is commonly used to manufacture the T-slot miter rail jig’s fastening components, screws, and other connections.

- T-rail fittings: T-rail fittings are usually made of aluminum alloy or plastic. These materials have excellent corrosion resistance and mechanical properties to ensure the stability and durability of the T-rail.

In short, to choose a suitable the Stopper, you need to choose according to the specific processing project and wood products. When choosing, you need to pay attention to factors such as the width of the T-shaped track. The height and length of the wood product. And the needs of the processing project to choose the appropriate specification and model.

T Track Stopper: An essential positioning device for sheet metal processing

Sheet metal processing is a method widely used in manufacturing and processing industries, where positioning and fixing are one of the key factors for processing accuracy and efficiency. In sheet metal processing, T Track Stopper, a small but practical positioning device, has become a very important tool.

What is T Track Stopper?

T-slot miter rail jig is a positioning device for T-track, which improves machining accuracy and efficiency by fixing and positioning items. It usually consists of stoppers and T-track fittings that keep items in place and secure during processing.

The application of T Track Stopper is very wide

In sheet metal processing, T Track Stopper is widely used. It can be used in various processing scenarios, such as sheet metal cutting, bending, punching, etc., and is especially useful for workpieces that require repeated processing. By using the T-slot miter rail jig, the processing personnel can fix the workpiece on the T-shaped track, accurately position and fix it, and avoid the deviation or falling off of the workpiece during the processing, thereby improving the processing accuracy and efficiency.

T Track Stopper also has the following advantages:

- Reliability and durability: T Track Stopper are usually made of materials such as metal and plastic, which has high strength and durability, and can withstand certain pressure and weight.

- Simple and easy to use: T-slot miter rail jig has a simple structure, easy to install and remove, convenient to store and carry, very convenient to use.

- Versatility: T Track Stopper can be used in various processing scenarios, such as sawing, drilling, planning, etc., and can accurately position and fix different types of workpieces.

When using The Stopper for sheet metal processing, it is necessary to select the appropriate specification and model according to the specific workpiece and processing project, and follow the instructions for proper installation and fixing. At the same time, you need to pay attention to safety issues to avoid hand injuries or equipment damage.

Design of the T Track Stopper

Adjustment screw: The adjustment screw is the part that adjusts the position and fixation of the stopper, and is usually made of metal. It needs to be designed with the size and shape of the stopper in mind, to be able to fit the stopper perfectly, and to adjust the position and fixation of the stopper by means of rotation.

In short, the design of T Track Stopper is carried out around the requirements and structure of T-shaped track. It needs to be designed with sufficient strength and stability taking into account the size and shape of the clamped item, while being able to fit perfectly with the T-track for precise positioning and fixing. In the process of using The Stopper, it is necessary to select the appropriate specification and model according to the specific processing project, and follow the instructions for proper installation and fixing.

Material of T track stopper

T Track Stopper is a positioning device for T-track, which can improve machining accuracy and efficiency by fixing and positioning items. A The Stopper usually consists of a stopper and a T-track fitting. Hope that helps you better understand its composition and performance.

Stoppers: Stoppers are usually made of aluminum alloy or stainless steel. These materials have excellent corrosion resistance and mechanical properties to ensure the stability and durability of the stopper.

In short, T-slot miter rail jig is a necessary positioning device for sheet metal processing, which can help processing personnel improve processing accuracy and efficiency. Its advantages lie in reliability and durability, and it is suitable for a variety of different processing scenarios. In sheet metal processing, the Stopper has become an indispensable tool, bringing a more efficient and precise processing experience to processing personnel.

T track stopper: a sharp tool to improve machining accuracy

With the development of manufacturing and processing industries, people’s requirements for machining accuracy are getting higher and higher. How to fix and position items during processing is one of the important factors affecting processing accuracy and efficiency. At this time, T Track Stopper, a small but practical positioning device, becomes a very important tool.

What is T Track Stopper?

T Track Stopper is a positioning device for T-track, which improves machining accuracy and efficiency by fixing and positioning items. It usually consists of stoppers and T-track fittings that keep items in place and secure during processing.

Advantages of T Track Stopper

The T-slot miter rail jig Stopper is very convenient to use, you only need to install it on the T-shaped track, adjust the position of the stopper and the control of the handle, and you can precisely position and fix the items. It can be used in a variety of different processing scenarios, such as sawing, drilling, planning, etc., and is especially useful for woodworking projects and metalworking projects that require repetitive processing.

The advantage of T track stopper lies not only in improving machining accuracy and efficiency, but also in its reliability and durability. It is usually made of materials such as metal and plastic, has high strength and durability, and can withstand certain pressure and weight. At the same time, the T Track Stopper has a simple structure, easy to install and disassemble, and convenient to store and carry.

When using T Track Stopper, it is necessary to select the appropriate specification and model according to the specific processing project, and follow the instructions for proper installation and fixing. At the same time, you need to pay attention to safety issues to avoid hand injuries or equipment damage.

Design of the T Track Stopper

The design of the T Track Stopper is based on the structure and requirements of the T-shaped track. It usually consists of stoppers and T-track fittings that improve the positioning and securing of items during machining. The following describes the design of the T Track Stopper in detail.

- Stopper: The stopper is the main component of the T-slot miter rail jig and is usually made of metal. Its shape is like a pair of pliers, which can clamp objects and fix them on the T-shaped track by means of handles or screws. The design of the stopper needs to take into account the size and shape of the item to be clamped. And be strong and stable enough to ensure that the item does not move or fall out during processing.

- T-Track Fitting: T-Track Fitting is the part used to support and hold the stopper, usually made of plastic or metal. Its design needs to take into account the size and shape of the stopper. So that it can fit perfectly with the stopper. Ensuring that the stopper slides and stays in place on the track. At the same time. The material of the The fittings needs to have sufficient strength and durability to withstand the pressure and weight during processing.

- Handle: The handle is the part that controls the movement and fixation of the stopper and is usually made of plastic or metal. The design of the handle needs to take into account ergonomics and user habits. So that the position and fixation of the stopper can be easily controlled. Thereby improving the efficiency and accuracy of processing.

In a word, The Stopper is a very practical positioning device. Which can help processing personnel improve processing accuracy and efficiency. Its advantages lie in reliability and durability, and it is suitable for a variety of different processing scenarios. In the manufacturing and processing industry, The Stopper has become an indispensable tool. Bringing more efficient and precise processing experience to processing personnel.