T track stopper: a good tool to improve the accuracy of sheet metal processing

T track stopper is a device for workpiece positioning and fixing, widely used in sheet metal processing, which can improve processing accuracy and efficiency. This article will discuss its role in sheet metal processing from the principles, application scenarios, and innovative applications of the T track stopper.

The principle of T track stopper

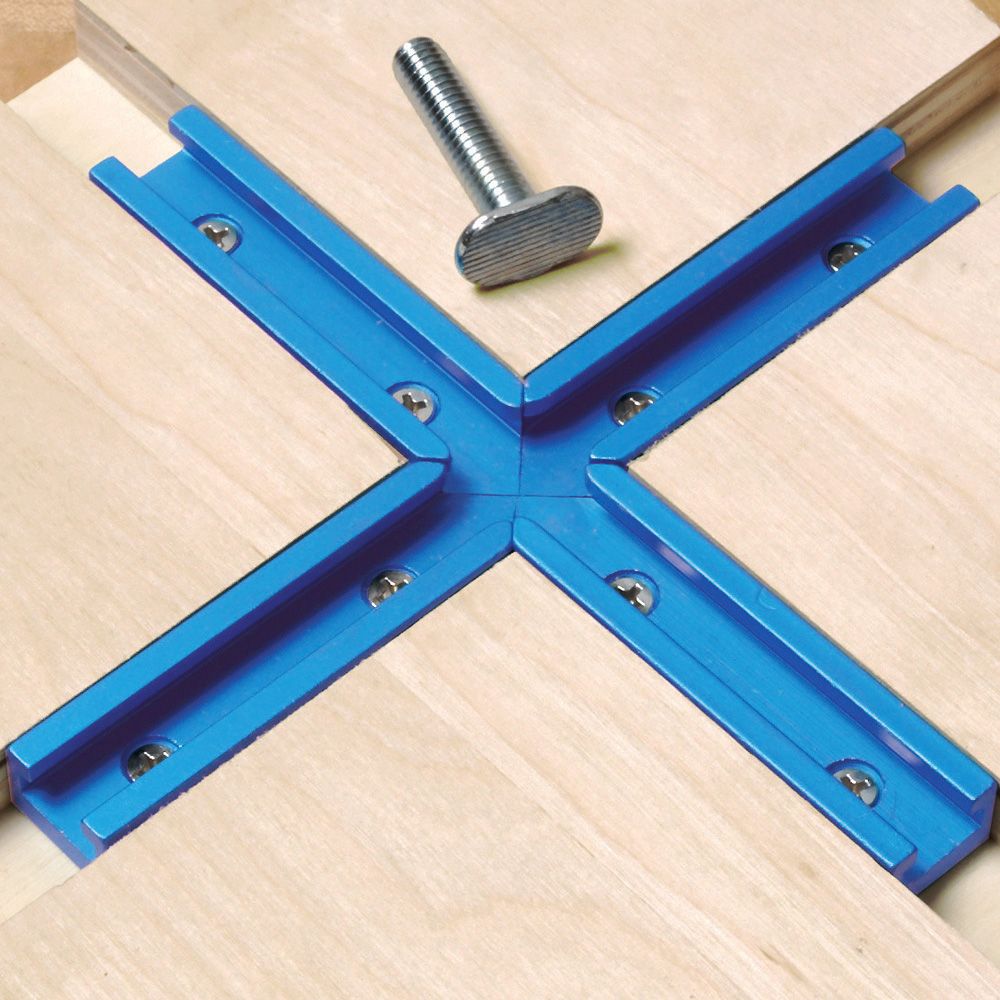

The T track stopper mainly uses the structure of the T-slot, and realizes the positioning and fixing of the workpiece by clamping the two sides of the T-slot. T-slot is a notch with a special structure, and different types of positioning devices can be installed inside the notch, such as T track stopper, etc., to realize the positioning and fixing of the workpiece.

Application scenarios of T track stopper

- Laser cutting: In the process of laser cutting, using T track stopper can improve cutting accuracy and efficiency, and avoid affecting the overall effect due to errors.

- Stamping forming: During the stamping forming process, the use of T track stopper can ensure that the workpiece will not move or deviate from the predetermined position, improving the forming accuracy and efficiency.

- Bending forming: During the bending forming process, the use of T-slot miter rail jig can ensure the positioning and fixing of the workpiece to ensure the consistency of bending angle and precision.

- Welding: During the welding process, the use of the stopper can ensure the positioning and fixing of the workpiece, avoid deformation or offset of the workpiece, and improve welding accuracy and efficiency.

Innovative application of T track stopper

In addition to being used in traditional sheet metal processing, T-slot miter rail jig has other innovative application scenarios. For example, in 3D printing, T track stopper can be used to fix and position the printing base to ensure printing accuracy and quality. In woodworking, the stopper can also be used to fix and position wooden boards to ensure processing accuracy and efficiency. In addition, T-slot miter rail jig can also be applied in pneumatic and hydraulic fields to control and fix the position of pipes and valves.

Application field of T track stopper

The stopper is a device for workpiece positioning and fixing, which has been widely used in many fields. Discuss the application fields of T-slot miter rail jig from the application scenarios of automobile industry, aviation industry, woodworking, metal processing and other fields.

- Automobile industry: In the automobile industry, the stopper is mainly used in many key links such as body welding, stamping forming, wheel assembly, and door processing. the use of stopper can ensure the positioning and fixing of the workpiece, thereby improving the machining accuracy and efficiency, and avoiding the overall effect being affected by errors. At the same time, the T-slot miter rail jig can also be adjusted according to different processing requirements, and has wide applicability. It is an indispensable processing tool in the automotive industry.

- Aviation industry: In the aviation industry, stopper is mainly used in many key fields such as fuselage welding and aircraft parts processing. the aviation industry has extremely high requirements on machining accuracy and efficiency. the use of the stopper can ensure the positioning and fixing of the workpiece, so as to maximize the machining accuracy and efficiency. At the same time, T-slot miter rail jig can also be adjusted to meet different processing requirements, bringing more convenience and benefits to the aviation industry.

Epilogue

The stopper is an important sheet metal processing tool, which can improve processing accuracy and efficiency and reduce processing costs. With the continuous advancement of technology and the continuous expansion of applications, it is believed that the application of T track stopper in sheet metal processing will become more and more extensive, bringing more convenience and benefits to the sheet metal processing industry. When using T-slot miter rail jig, you need to pay attention to the operation method and safety matters to ensure that it can achieve the best processing effect.

Application of T track stopper in woodworking

T-slot miter rail jig is a common positioning device, which is widely used in the field of machining. In addition to being used in traditional sheet metal processing, T track stopper is also widely used in woodworking. This article will discuss its application in woodworking processing from the types, application scenarios, and selection methods of T track stoppers.

Types of T track stoppers

According to different usage methods and control mechanisms, T track stopper can be divided into handle type, knob type, sliding type, spring type and other types.

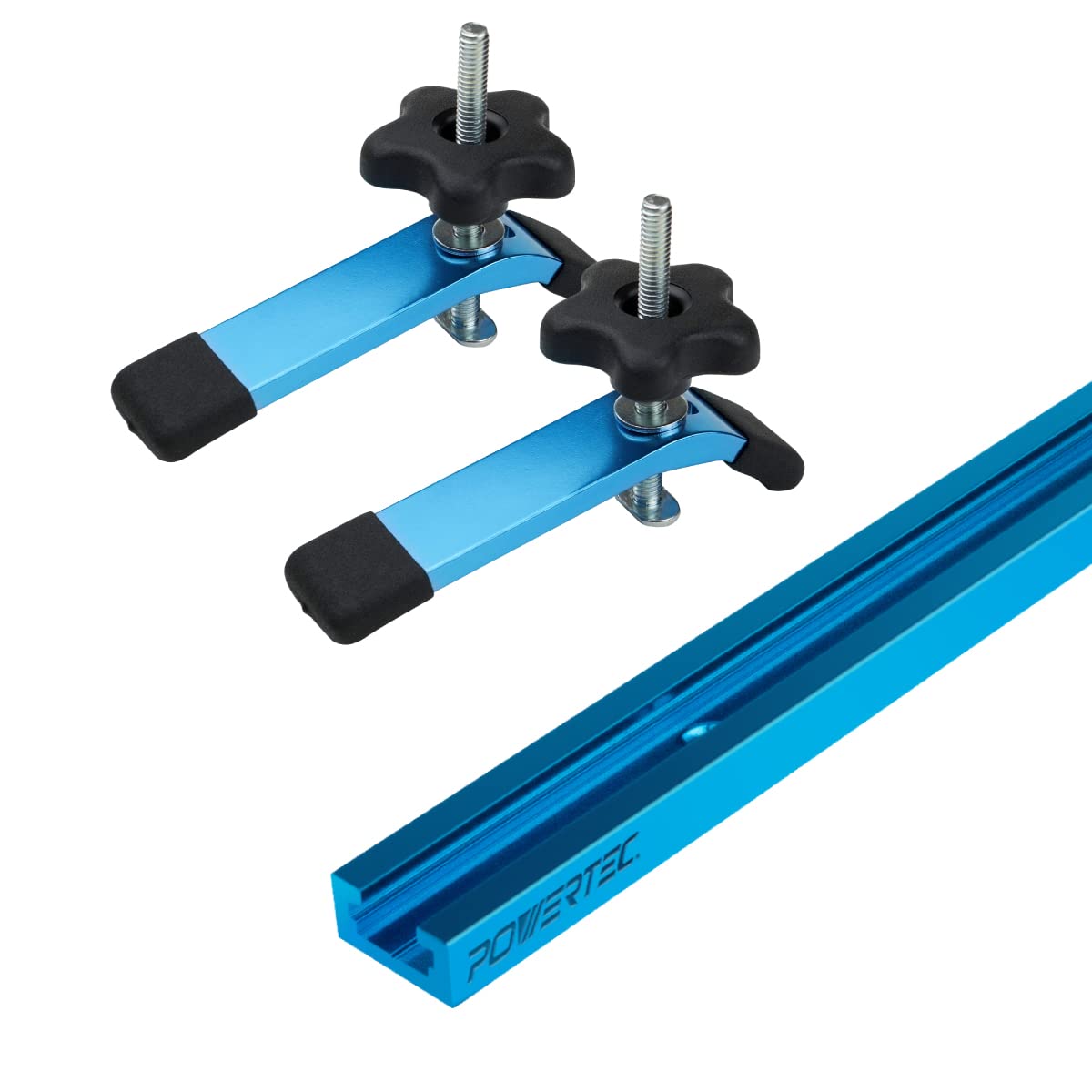

- The handle-type T track stopper uses a handle to adjust the position and fixing degree of the workpiece. the handle-type T-slot miter rail jig is easy to operate and is suitable for scenes that require frequent adjustment of the position and degree of fixation of the workpiece.

- Knob type the stopper uses a knob to adjust the position and degree of fixation of the workpiece. the knob-type the stopper is easy to operate and is suitable for scenes that require frequent adjustment of the position and degree of fixation of the workpiece.

- Sliding T-slot miter rail jig uses a sliding block to adjust the position and fixing degree of the workpiece. the sliding stopper is more reliable and suitable for scenarios where workpieces need to be stably fixed.

- The spring type the stopper uses a spring to control the degree of fixation. the spring-type T-slot miter rail jig is adjustable in degree of fixation and has strong applicability.

Application scenarios of T track stopper

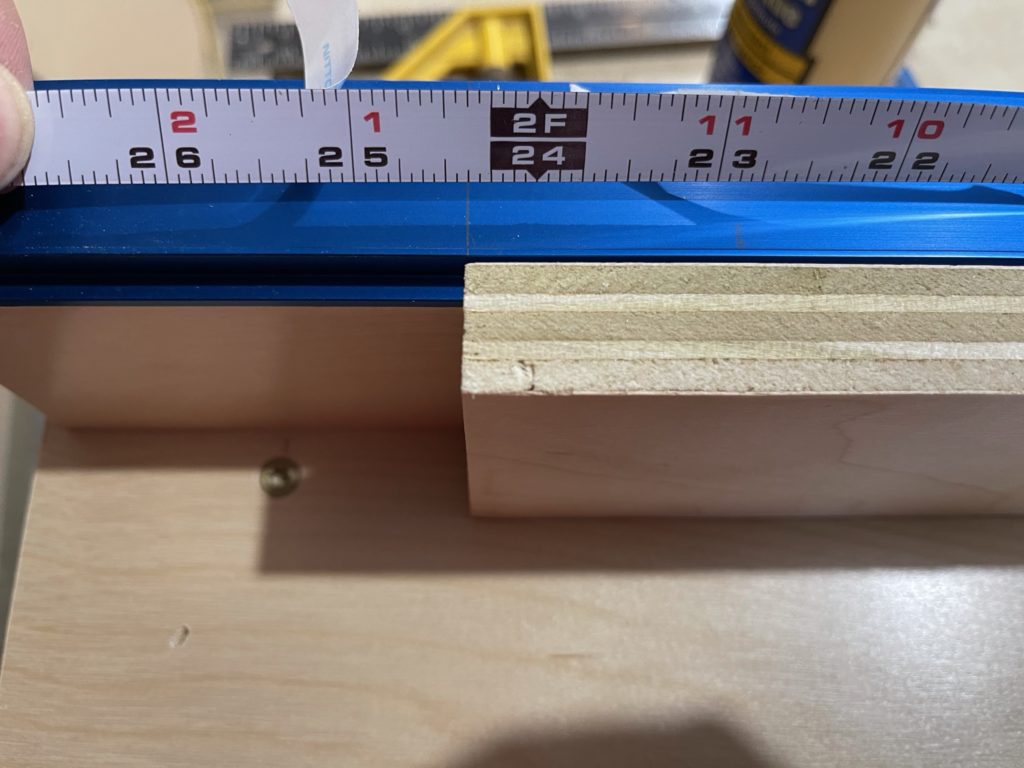

- Plank positioning: In woodworking, the stopper can be used to position and fix planks to ensure processing accuracy and efficiency. For example, the use of T-slot miter rail jig can fix the wood board on the cutting machine to avoid affecting the cutting quality due to the instability of the wood board.

- Processing accuracy control: In woodworking processing, the stopper can be used to control processing accuracy. For example, when using woodworking tools for cutting, drilling, etc., the T track stopper can be used to fix the workpiece to avoid deviation or damage to the workpiece due to improper operation.

- Chamfering: In woodworking, T-slot miter rail jig can also be used for chamfering. For example, when chamfering, stopper can be used to fix the angle to ensure the accuracy and consistency of chamfering.

- Mold making: In woodworking, the stopper can also be used for mold making. For example, when making arched doors and window frames, T-slot miter rail jig can be used to fix and position molds to ensure the accuracy and consistency of mold making.

T track stopper selection method

When selecting a stopper, the following factors need to be considered:

- Processing method: According to different processing methods, choose different types of T-slot miter rail jig. For example, when cutting, it is recommended to choose a sliding the stopper to ensure the stability of the board. When chamfering, it is recommended to choose the knob type stopper to ensure the accuracy of the angle.

- Workpiece size: According to different workpiece sizes, select the appropriate T-slot miter rail jig size. For example, when machining large-sized workpieces, it is recommended to choose a large-sized the stopper to ensure stability.

- Processing requirements: According to different processing requirements, select the appropriate the stopper. For example, when making molds, it is necessary to choose a T-slot miter rail jig that can fix and position the mold to ensure the accuracy of mold making.

Epilogue

T track stopper has an important application in woodworking processing, which can improve the precision and efficiency of woodworking processing and reduce processing costs. With the continuous advancement of technology and the continuous expansion of applications, it is believed that the application of T track stopper in woodworking processing will become more and more extensive, bringing more convenience and benefits to the woodworking processing industry.

Application of T track stopper in sheet metal processing

T-slot miter rail jig is a common positioning device that plays a vital role in sheet metal processing. In addition to providing stable positioning and fixing effects during processing, the stopper has other application scenarios. This article will discuss its application in sheet metal processing from the aspects of innovative application, automated production, and customized processing of stopper.

Innovative application of T track stopper

The application of the stopper is not limited to traditional sheet metal processing, and its application in other fields is becoming more and more extensive. For example, in 3D printing, stopper can be used to fix and position the printing base to ensure printing accuracy and quality. In woodworking, T-slot miter rail jig can also be used to fix and position wooden boards to ensure processing accuracy and efficiency. In addition, stopper can also be applied in pneumatic and hydraulic fields to control and fix the position of pipes and valves.

Automated production of T track stopper

With the development of automation technology, more and more sheet metal processing manufacturers have begun to adopt automated production lines to improve production efficiency and reduce costs. In an automated production line, T-slot miter rail jig can be used in conjunction with robotic arms, conveyor belts and other equipment to achieve automated positioning and fixing operations. For example, by cooperating with the robot arm, T track stopper can realize automatic parts assembly, welding and other operations to improve production efficiency and quality.

Customized processing of T track stopper

With the changing needs of consumers, more and more sheet metal processing manufacturers have begun to provide customized processing services to meet the individual needs of customers. In customized processing, T-slot miter rail jig can be used to locate and fix special workpieces provided by customers to ensure processing accuracy and efficiency. In addition, the stopper can also be used in conjunction with advanced equipment such as laser cutting and CNC stamping to achieve customized processing operations.

Precautions

When installing the Stopper, you need to pay attention to the following:

- Choose the appropriate T-slot miter rail jig size and model.

- When installing T Track Stopper and T-shaped track, you need to strictly follow the instructions to ensure correct and firm installation.

- When fixing the Stopper, it is necessary to ensure that the position of the T-slot miter rail jig is correct and stable to prevent it from loosening or moving during use.

- When adjusting the position of the T Track Stopper, it is necessary to pay attention to the strength of the handle and whether the workpiece can be firmly fixed on the T-shaped track.

How to install T track stopper?

In short, the installation method of T-slot miter rail jig is very simple, just follow the instructions. Through the correct installation method, the stability and safety of the Stopper can be ensured, and the machining accuracy and efficiency can be improved. When using T Track Stopper, you need to pay attention to the installation method and precautions, and follow the instructions for use.

Pay attention to the environment

When using the stopper, you need to pay attention to the usage environment. T-slot miter rail jig needs to be placed in a dry, ventilated and temperature-friendly environment, away from moisture, heat or cold. At the same time, when using the T track stopper, it is necessary to avoid using it in harsh environments such as dust, humidity or high temperature, so as to avoid affecting the use effect and service life.

Epilogue

In sheet metal processing, T-slot miter rail jig can not only provide stable positioning and fixing effects, but also has other innovative applications, automated production, customized processing and other applications. With the continuous advancement of technology and the continuous expansion of applications, it is believed that the application of T track stopper in sheet metal processing will become more and more extensive, bringing more convenience and benefits to the sheet metal processing industry.

Precautions for using T track stopper

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. When using the T track stopper, some usage precautions need to be observed to ensure safe and effective use. This article will introduce the precautions for using T-slot miter rail jig in detail, hoping to help you better understand and use the stopper.

Choose the right T track stopper

Before using T-slot miter rail jig, you need to choose a suitable stopper. the stopper can be divided into handle type, knob type, sliding type, spring type and other types according to different control mechanisms. When selecting a T-slot miter rail jig, it is necessary to select a suitable the stopper according to the processing requirements and the characteristics of the workpiece to ensure the best use effect.

Correctly install the T track stopper

Before installing the T-slot miter rail jig, the and the stopper need to be cleaned first. When installing, it is necessary to ensure that the stopper is placed in the correct groove, and adjust the position and degree of fixation according to the size of the workpiece and processing requirements to ensure processing accuracy and efficiency. If it is found that the T track is uneven or the T-slot miter rail jig is abnormal, it needs to be stopped in time and repaired or replaced.

Be safe

When using the stopper, you need to pay attention to safety. When processing, it is necessary to wear safety protection equipment such as gloves and goggles to avoid accidental injuries. When using the stopper, you need to be careful not to touch the knife to avoid accidental injury. At the same time, when operating the T-slot miter rail jig, it is necessary to pay attention to the operating specifications and follow the operating procedures to avoid safety accidents.

Pay attention to maintenance

When using the stopper, attention needs to be paid to maintenance to ensure service life and stability. During use, it is necessary to pay attention to cleaning the T-shaped track and the stopper to avoid dust and impurities from affecting the working effect. At the same time, regular inspection and maintenance of the T-slot miter rail jig is required, including cleaning and lubrication control mechanisms, etc. If the stopper is found to be abnormal, it needs to be repaired or replaced in time.

Pay attention to the environment

When using the stopper, you need to pay attention to the usage environment. T-slot miter rail jig needs to be placed in a dry, ventilated and temperature-friendly environment, away from moisture, heat or cold. At the same time, when using the T track stopper. It is necessary to avoid using it in harsh environments such as dust. Humidity or high temperature. So as to avoid affecting the use effect and service life.

How to install T track stopper?

Adjust the T-slot miter rail jig position

After the Stopper is secured. A position adjustment is required to ensure that the stopper is positioned above the desired position on the workpiece. When adjusting the position of the Stopper, you need to pay attention to the following points:

- Make sure the handle of the T-slot miter rail jig is released.

- Adjust the position of the stopper until the workpiece is in the correct and stable position.

- Fix the stopper and adjust the handle strength to ensure that the workpiece can be firmly fixed on the T-rail.

In a word, when using stopper, you need to pay attention to choose the appropriate the stopper. Install the T-slot miter rail jig correctly. Pay attention to safety. Maintenance and use environment. So as to ensure safe and effective use. When using the stopper, it is necessary to abide by the relevant operating procedures and operating procedures to avoid accidents.

Advantages and application scenarios of T track stopper

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. Compared with traditional positioning devices, T-slot miter rail jig has many advantages and can be applied in various scenarios. This article will introduce the advantages and application scenarios of the stopper in detail, hoping to help you better understand and use stopper.

Advantages of T track stopper

- Precise positioning: the stopper can achieve precise positioning by fixing and positioning the workpiece, avoiding the overall effect being affected by errors.

- High stability: T track stopper adopts control mechanisms such as fixed blocks, adjustment rods, handles, knobs, sliding blocks, etc., which can realize stable fixing of workpieces and avoid workpieces from moving or shaking.

- Easy to operate: T-slot miter rail jig is easy to operate. It needs to adjust the position and fixing degree of the workpiece through control mechanisms such as handles, knobs, and sliders. It is suitable for different operating requirements and processing scenarios.

- Wide range of applications: the stopper can be applied to various scenarios such as making furniture, making models, and doing DIY projects, and is suitable for different workpieces and processing needs.

- Cost saving: stopper can improve machining accuracy and efficiency by fixing and positioning workpieces, reduce machining costs and improve production efficiency.

Application scenarios of T track stopper

- Making furniture: When making furniture, the stopper and T-shaped track can be used to fix and position the workpiece, improving processing accuracy and efficiency. For example, when making cabinet doors, drawers and other furniture parts, you can use T track stopper to achieve precise positioning and fixing.

- Model making: When making models, T-slot miter rail jigs and T-shaped tracks can be used to precisely position the workpiece to avoid affecting the overall effect due to errors. For example, to make aircraft models, car models, etc., you can use stopper to achieve precise positioning and fixing of workpieces.

- Do DIY projects: When doing DIY projects, the stopper and the can be used to help DIY enthusiasts complete various processing projects more easily. For example, to make simple furniture, DIY lamps, etc., you can use T-slot miter rail jig to quickly locate and fix the workpiece.

- Machining: In machining, stopper can be applied to various processing scenarios, such as drilling, cutting, etc. By accurately positioning and fixing the workpiece, the machining accuracy and efficiency can be improved.

- Woodworking processing: In woodworking processing, the stopper can be applied to making furniture, making wooden tools and other scenes. By accurately positioning and fixing the workpiece, the machining accuracy and efficiency can be improved.

How to install T track stopper?

Fix the Stopper: After the Stopper is inserted into the T-shaped track, fix the T-slot miter rail jig in the T-shaped track with screws or other fixing parts. When fixing the T Track Stopper, you need to pay attention to the following points:

- Make sure the length and diameter of the fixing part matches the T-track, not too long or too short.

- When fixing the Stopper, it is necessary to ensure that the position of the T-slot miter rail jig is correct and stable to prevent it from loosening or moving during use.

In short, the stopper has the advantages of precise positioning, high stability, easy operation, wide application range, cost saving, etc., and can be applied in various scenarios. When using the stopper, you need to pay attention to safety and maintenance, so as to better realize the processing and production of workpieces.

The structure and components of T track stopper

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. In the use of T-slot miter rail jig, it is very important to understand its structure and components, so as to better understand and use T track stopper. This article will introduce the structure and components of the stopper in detail, hoping to help you better understand and use T-slot miter rail jig.

Components of the T track stopper

stopper consists of the following components:

- Positioning Blocks: Positioning blocks, usually made of metal or plastic, hold and position workpieces through grooves in the T-track.

- Fixing block: the fixing block is usually composed of control mechanisms such as handles, knobs, and sliding blocks, and a fixing plate made of metal or plastic. the position and degree of fixation of the workpiece can be fixed and adjusted through control mechanisms such as handles, knobs, and sliding blocks.

- Adjusting rod: the adjusting rod is usually made of metal or plastic, which can be used to adjust the position and fixing degree of the fixing block, so as to realize the precise positioning and fixing of the workpiece.

- Handle: the handle is usually made of plastic or rubber and can be used to tighten or loosen the fixing block and adjust the position and fixing degree of the workpiece.

- Knobs: Knobs are usually made of metal and can be used to adjust the position and fixing degree of the fixing block, so as to realize the precise positioning and fixing of the workpiece.

- Sliding block: the sliding block is usually made of metal or plastic, and the position and fixing degree of the workpiece can be adjusted through the sliding mechanism.

- Spring: the spring is usually made of steel, and can realize the fastening of the fixed block by providing opposing force and rebound force.

- Fixing plate: the fixing plate is usually made of metal or plastic and can be used to fix the various components of the T-slot miter rail jig.

Type of T track stopper

The stopper can be divided into the following types according to different control mechanisms:

- Handle-type T-slot miter rail jig: Handle-type T track stopper usually adopts a handle control mechanism, and the position and fixing degree of the workpiece can be adjusted through the handle. the handle-mounted stopper is easy to operate and is suitable for smaller and lighter workpieces.

- Knob type T-slot miter rail jig: Knob type the stopper usually adopts a knob control mechanism, and the position and fixing degree of the workpiece can be adjusted through the knob. Knob-type the stopper is more precise and stable for larger and heavier workpieces.

- Sliding T-slot miter rail jig: Sliding stopper usually adopts a sliding block control mechanism, and the position and fixing degree of the workpiece can be adjusted through the sliding block. the sliding the stopper is easy to operate and is suitable for smaller and lighter workpieces.

- Spring-type T-slot miter rail jig: Spring-type T track stopper usually adopts a spring control mechanism, which can realize the fastening of the fixed block by providing reverse force and rebound force. the spring-loaded the stopper is easy to operate and is suitable for smaller and lighter workpieces.

According to different processing requirements and workpiece characteristics, different types of T-slot miter rail jigs can be selected to better realize the positioning and fixing of workpieces.

In short, understanding the structure and components of the stopper can better understand and use stopper, and improve machining accuracy and efficiency. When using T-slot miter rail jig, you need to pay attention to safety and maintenance, so as to better realize the processing and production of workpieces.

The use of T track stopper and T track

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. In the use of stopper, it is very important to cooperate with the T-slot miter rail jig. This article will introduce the use of T track stopper and the in detail, hoping to help you better understand and use the stopper.

Principle of T track stopper and T track

The stopper can be used in conjunction with the T-shaped track, and the workpiece can be fixed and positioned through the groove of the T-shaped track, thereby improving machining accuracy and efficiency.

T-rails are usually made of aluminum and have a T-shaped section that can be joined by slots to create tracks of different lengths. In the T track, the groove can be used to place the stopper, so as to fix and position the workpiece.

T-slot miter rail jig is usually made of metal or plastic, and the position and fixing degree of the workpiece can be fixed and adjusted through control mechanisms such as handles, knobs, and sliding blocks. When using the stopper, it needs to be placed in the groove in the T-shaped track, and the position and fixation degree of the workpiece can be fixed and adjusted through control mechanisms such as handles, knobs, and sliders, so as to achieve precise positioning and fixing of the workpiece.

Advantages and disadvantages of T track stopper and T track

The combination of T-slot miter rail jig and T track has the following advantages and disadvantages:

- Advantage:

- Precise positioning: the precise positioning and fixing of the workpiece can be achieved through the combined use of the stopper and the T-shaped track.

- Improve processing efficiency: Through the combined use of the stopper and T-shaped track, the processing efficiency can be improved and the workpiece can be prevented from sliding or tilting during processing.

- Simple and easy to use: the use of T-slot miter rail jig and is easy to understand and does not require complicated operation skills.

- Shortcoming:

- Need to be used together:Stopper and T-shaped track need to be used together, if there is a problem with one of them, it will affect the entire machining process.

- Not suitable for all workpieces: the stoppers and T-tracks are suitable for most workpieces, but for some special shaped workpieces, other positioning devices may be required.

- Higher cost: the cost of T-slot miter rail jig and T-shaped track is higher, which may be a certain pressure for some users with limited budget.

How to care and maintain the stopper and T track?

In order to ensure the normal use of the stopper and the T-shaped track, regular maintenance and maintenance are required:

- Cleaning: Regularly clean the and T-slot miter rail jig to avoid dust and impurities from affecting the working effect.

- Lubrication: Use oil or grease regularly to keep the stopper and the running smoothly.

- Adjustment: Regularly adjust the position and degree of fixation of the stopper to ensure machining accuracy and efficiency.

- Inspection: Regularly inspect the and T-slot miter rail jig for damage or malfunction.

Summarize

The combination of stopper and it can improve machining accuracy and efficiency, and is suitable for making furniture, models, and DIY projects. When using the stoppers and T-shaped tracks, you need to pay attention to issues such as cooperative use, adjustment of position and degree of fixation, care and maintenance, in order to achieve the best results. Although the cost of T-slot miter rail jig and the is higher, its advantages are obvious for machining projects that require high precision and high efficiency.

How to choose the T track stopper that suits you

T track stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. When choosing a T-slot miter rail jig that suits you, you need to consider a variety of factors, such as project type, workpiece size, processing requirements, etc. This article will introduce in detail how to choose a stopper that suits you, hoping to help you better understand and choose a stopper.

Learn about the types of T track stoppers

Before choosing a T track stopper, you need to understand the different types of the stoppers. Generally, T-slot miter rail jigs can be divided into the following categories:

- Handle-type stopper: the handle-type the stopper controls the position and fixing degree of the workpiece through the handle, which is suitable for small workpieces and projects that require high machining accuracy.

- Sliding T-slot miter rail jig: the sliding the stopper controls the position and fixing degree of the workpiece through the slider, which is suitable for large workpieces and projects that require high processing efficiency.

- Self-locking T track stopper: the self-locking T-slot miter rail jig can control the position and fixing degree of the workpiece through the self-locking mechanism, and is suitable for various processing projects.

- Knob-type T track stopper: Knob-type the stopper can control the position and fixing degree of the workpiece through the knob, which is suitable for projects that require high processing accuracy and efficiency.

Consider project type and workpiece size

When choosing the T-slot miter rail jig that suits you, you need to consider the type of project and the size of the workpiece. For example, when making furniture, it is necessary to choose a suitable the stopper, which is suitable for large workpieces and projects that require high processing accuracy. When making models, you need to choose a stopper that is suitable for small workpieces and requires high machining accuracy.

For different workpiece sizes, different types of T-slot miter rail jigs also need to be selected. If the workpiece is small, you need to choose a handle type or self-locking the stopper to ensure machining accuracy. And if the workpiece is large, you need to choose a sliding or knob T track stopper to improve processing efficiency.

Consider processing needs

When choosing the T-slot miter rail jig that suits you, you also need to consider the processing requirements. For example, when drilling holes, it is necessary to choose a stopper that can accurately position and fix the workpiece to ensure that the drilling position is accurate.

When performing cutting and other processing, it is necessary to choose a stopper that can stably fix the workpiece to prevent the workpiece from sliding or tilting during processing. If multiple machining operations are required, you need to choose a T-slot miter rail jig that can quickly adjust the position and degree of fixation to improve machining efficiency.

Choose a reputable brand

When choosing a T track stopper, you also need to choose a reputable brand. By choosing a reputable brand, you can guarantee the quality and performance of the stopper, and avoid processing errors or accidents caused by the use of bad brand T-slot miter rail jigs.

Consider price and value for money

Finally, when choosing a stopper that suits you, you also need to consider price and cost performance. Price is an important factor for many users, so there is a tradeoff between price and performance. Choosing a stopper with reasonable price and high-cost performance can guarantee the processing quality and efficiency while saving costs.

Summarize

To choose the T-slot miter rail jig that suits you, you need to consider many factors, such as project type, workpiece size, processing requirements, brand reputation and price, etc. By understanding the types and characteristics of T track stoppers, combined with your own processing needs and budget, you can choose a stopper that suits you, so as to improve processing accuracy and efficiency.

T track stopper: Add precision to your woodworking projects

T-slot miter rail jig is a positioning device for The, which can improve machining accuracy and efficiency by fixing and positioning workpieces. Whether you are a professional woodworker or a DIY enthusiast, you can use the T track stopper to improve work efficiency and machining precision. This article will introduce the features, advantages and usage methods of T track stopper in detail to help you better understand and use this tool.

How to use T track stopper?

The usage of T track stopper is as follows:

- Determine the position of the workpiece: place the workpiece to be processed on the workbench, and fix the workpiece on the T-shaped track by adjusting the position of the T track stopper and the handle control. Make sure that the position of the workpiece is correct and stable.

- Perform machining operations: By using machining tools, perform required machining operations such as drilling, cutting, etc.

- Adjust the position of the T-slot miter rail jig: When a new processing operation is required on the workpiece, the position of the stopper needs to be adjusted to ensure that the workpiece can be positioned and fixed accurately.

- Check the processing quality: After the processing is completed, it is necessary to check the processing quality to ensure that the workpiece meets the requirements.

Application scenarios of T track stopper

T-slot miter rail jig can be applied to the following scenarios:

- Making furniture: When making furniture, T track stopper can ensure the precise positioning and fixing of workpieces, improving processing efficiency and quality.

- Model making: When making models, The stopper can precisely locate small parts to avoid affecting the overall effect due to errors.

- For DIY projects: When it comes to DIY projects, the T-slot miter rail jig can help DIY enthusiasts complete various processing projects more easily.

Precautions for T track stopper

When using The stopper, you need to pay attention to the following:

- Select the appropriate T-slot miter rail jig size and model.

- When installing the stopper and T-shaped track, it is necessary to strictly follow the instructions to ensure correct and firm installation.

- When fixing the T track stopper, it is necessary to ensure that the position of the T-slot miter rail jig is correct and stable to prevent it from loosening or moving during use.

- When adjusting the position of the T track stopper, it is necessary to pay attention to the strength of the handle and whether the workpiece can be firmly fixed on the.

- When using the The stopper, you need to wear proper safety gear, such as goggles, earplugs, etc., to ensure safety.

In the process of processing, it is necessary to pay attention to the safe use and maintenance of tools at all times to avoid accidents caused by improper use.

Install T Track Stopper

The installation method of The Stopper usually has the following steps:

Insert the T Track Stopper into the T-Track: First, insert the T-slot miter rail jig into the T-Track and make sure the stopper is positioned over the desired location of the workpiece. When inserting the The Stopper, you need to ensure that the insertion position is correct to avoid damage to the Stopper.

Summarize

T-slot miter rail jig is a practical tool that can help woodworkers and DIY enthusiasts to improve work efficiency and processing precision. Through correct installation and use, T track stopper can improve processing quality and safety, and reduce processing errors and accidents. When using the stopper, you need to pay attention to safety and maintenance, and follow the instructions for use. I believe that with the application of T-slot miter rail jig, your woodworking projects will become more precise and efficient.

Fixing method and adjustment method of T track stopper

The Stopper is a positioning device for T-track, which can improve machining accuracy and efficiency by fixing and positioning items. When using T Track Stopper, the correct fixing method and adjustment method are very important, which can ensure the precise positioning and fixing of the workpiece, thereby improving processing efficiency and quality. In this article, we will introduce the fixing method and adjustment method of T-slot miter rail jig, hoping to help you use T Track Stopper better.

Fixing method of T Track Stopper

There are usually two ways to fix the T-slot miter rail jig:

Handle fixing method: The handle fixing method is a common fixing method. By rotating the handle, the workpiece can be clamped. When using the handle fixing method, you need to pay attention to the following points:

Make sure the handle turns smoothly and should not be too tight or too loose.

When clamping the workpiece, it is necessary to properly adjust the force of the handle to ensure that the workpiece can be firmly fixed on the T-shaped track.

Screw fixing method: screw fixing method is a firmer fixing method, which is suitable for workpieces that require precision machining. When using the screw fixing method, you need to pay attention to the following points:

Make sure the length and diameter of the screws match the T-track, not too long or too short.

When fixing the workpiece, it is necessary to properly adjust the strength of the screw to ensure that the workpiece can be firmly fixed on the T-shaped track.

How to adjust the T Track Stopper?

The adjustment methods of T Track Stopper are usually as follows

- Adjust stop position

When using the T-slot miter rail jig, if the position of the workpiece is not correct, the position of the stopper needs to be adjusted. When adjusting the position of the stopper, pay attention to the following points:

- Make sure the handle of the Stopper is released.

- Adjust the position of the stopper until the workpiece is in the correct and stable position.

- Fix the stopper and adjust the handle strength to ensure that the workpiece can be firmly fixed on the T-rail.

- Adjust handle strength

Using the The Stopper, it is necessary to properly adjust the strength of the handle to ensure that the workpiece can be firmly fixed on the T-shaped track. Adjusting the strength of the handle, you need to pay attention to the following points:

- Make sure the handle rotates smoothly.

- Adjust the handle strength until the workpiece is securely seated on the T-rail, but not too tight or too loose.

- Replacement parts

Using the T-slot miter rail jig, if the stopper or other accessories are damaged or worn, they need to be replaced in time to ensure the normal use of the T Track Stopper. Replacing accessories, pay attention to the following points:

- Make sure that the size and model of the new accessories match the original ones.

- When replacing accessories, you need to follow the instructions to ensure correct and stable installation.

In short, the fixing method and adjustment method of The Stopper are very important, which can ensure the precise positioning and fixing of the workpiece, thereby improving the processing efficiency and quality. When using T-slot miter rail jig, you need to choose the appropriate specification and model according to the specific processing project and wood product, and pay attention to the fixing method and adjustment method during use. By using the T Track Stopper correctly, the workpiece processing efficiency can be improved, the processing safety can be enhanced. And the processing quality can be improved.