Power of Lathes: A Comprehensive Guide to Lathe Projects

Introduction

In the realm of woodworking and metalworking, lathes stand as indispensable tools, capable of transforming raw materials into intricate masterpieces. Whether you’re a seasoned craftsman or an aspiring woodworker, lathe projects offer an avenue to unleash creativity, hone skills, and produce functional or decorative items that enhance your home or workshop.

Understanding Lathes and Their Capabilities

Lathes are machines that rotate a workpiece, allowing a cutting tool to shape it into desired forms. They primarily function to create cylindrical or conical shapes, with the ability to perform various operations, including:

-

Turning: Removing material from the workpiece to create a smooth, rounded surface.

-

Facing: Flattening the end of a workpiece perpendicular to its axis.

-

Boring: Enlarging an existing hole or creating a new one within the workpiece.

-

Threading: Cutting helical grooves onto the workpiece to create a screw-like pattern.

-

Parting: Separating a workpiece into two distinct pieces along a defined line.

Essential Lathe Tools and Accessories

To embark on your lathe projects, you’ll need a basic set of tools and accessories:

-

Lathe Tool Rest: A support for the cutting tool, ensuring precise control and stability during operation.

-

Cutting Tools: A variety of cutting tools, including chisels, gouges, and parting tools, for different shaping tasks.

-

Chucks and Adapters: These secure the workpiece to the lathe spindle, allowing for various types of mounting.

-

Measuring Tools: Calipers, micrometers, and gauges for accurate measurement and dimension control.

-

Safety Gear: Protective glasses, gloves, and a dust mask to safeguard yourself from hazards.

Types of Lathes and Their Applications

Lathes come in various types, each suited for specific purposes:

-

Wood Lathes: Designed for shaping wooden workpieces, ideal for creating bowls, spindles, and decorative elements.

-

Metal Lathes: Precision instruments for machining metal workpieces, producing parts like gears, shafts, and bushings.

-

Mini Lathes: Compact and versatile, suitable for small-scale projects in both wood and metalworking.

Choosing the Right Lathe Project

When selecting a lathe project, consider your skill level, available tools, and desired outcome. Start with simple projects like bowls or spindles to gain confidence, then progress to more complex tasks like threading or parting.

Safety Guidelines for Lathe Operations

Safety is paramount when working on a lathe. Always follow these guidelines:

-

Secure the workpiece: Ensure the workpiece is firmly mounted in the chuck or between centers to prevent accidents.

-

Maintain proper posture: Stand with a balanced stance, knees slightly bent, and keep your hands away from rotating parts.

-

Wear appropriate PPE: Use protective glasses, gloves, and a dust mask to shield yourself from hazards.

-

Never operate the lathe while impaired: Avoid operating the lathe while under the influence of alcohol or drugs.

-

Stay alert and focused: Maintain full attention on the task at hand and avoid distractions while operating the lathe.

Basic Lathe Operations for Beginners

Start with these fundamental lathe operations to master the basics:

-

Rough Turning: Initial shaping of the workpiece to remove excess material and establish the desired form.

-

Smoothing: Refining the surface of the workpiece to eliminate irregularities and achieve a smooth finish.

-

Detailing: Adding intricate details, such as grooves, ridges, or decorative elements, to enhance the appearance.

-

Sanding: Smoothing the surface with sandpaper to achieve a polished, professional finish.

Intermediate Lathe Projects to Elevate Your Skills

Once you’ve mastered the basics, venture into these intermediate projects:

-

Creating a Pen: Combine woodturning and metalworking skills to craft a personalized pen.

-

Turning a Bowl with a Foot: Shape a wooden bowl with a decorative foot for added elegance.

-

Threading a Bolt: Learn the process of creating screw threads on a metal workpiece.

-

Making a Candle Holder: Design and turn a wooden candle holder with intricate details.

Advanced Lathe Projects for Experienced Craftsmen

For experienced woodworkers and metalworkers, these projects offer a challenge:

-

Turning a Chess Set: Create a complete chess set from wood, including intricate pieces and a board.

-

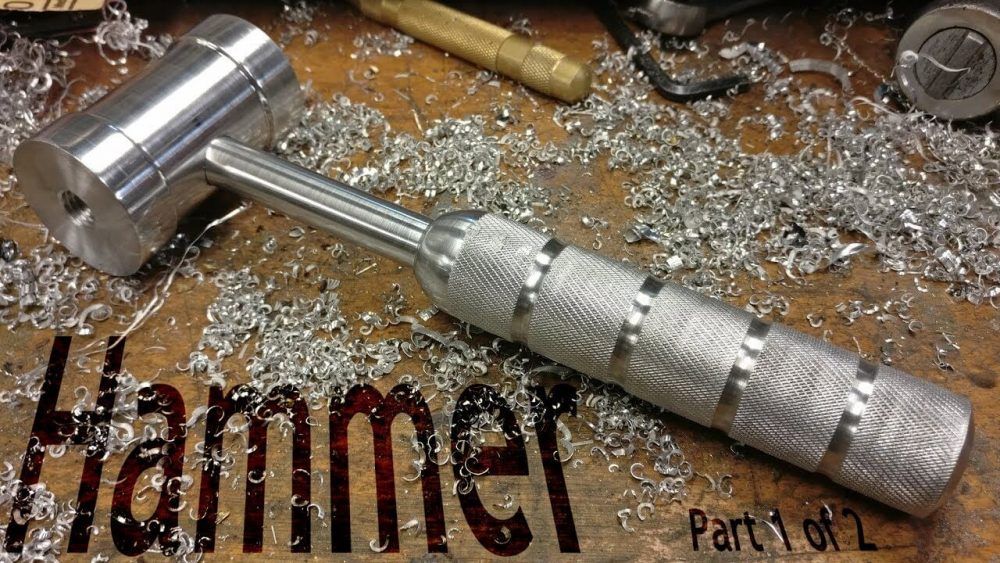

Machining a Gear: Produce a functional gear from metal using precise lathe techniques.

-

Turning an Intricate Spindle: Shape a complex spindle with multiple decorative elements and varying diameters.

-

Creating a Custom Table Lamp: Design and turn a unique table lamp from wood or metal.

-

Resources for Learning Lathe Techniques

Embarking on lathe projects can be an exciting yet daunting experience. Here are some resources to enhance your learning journey:

- Books and Online Tutorials: Numerous books and online tutorials cater to woodturning and metalworking, offering detailed instructions, project ideas, and safety tips.

- Lathe Forums and Communities: Online forums and communities connect aspiring and experienced lathe enthusiasts, allowing for knowledge sharing, troubleshooting assistance, and project inspiration.

- Woodworking or Metalworking Classes: Consider enrolling in woodworking or metalworking classes to gain hands-on experience and personalized guidance under the supervision of a skilled instructor.

- YouTube Channels: Many YouTube channels dedicated to woodworking and metalworking offer instructional videos featuring lathe techniques, project demonstrations, and valuable tips.

Maintenance and Care for Your Lathe

Just like any tool, proper care is crucial to ensure your lathe’s longevity and optimal performance. Here are some maintenance practices:

- Cleaning and Lubrication: Regularly clean your lathe to remove wood shavings, metal debris, and dust buildup. Follow the manufacturer’s instructions for lubricating moving parts to prevent friction and wear.

- Sharpening Cutting Tools: Maintain sharp cutting tools for efficient and clean cuts. Learn how to sharpen your lathe tools using a sharpening stone or invest in a sharpening jig.

- Belt Maintenance: Inspect and replace lathe belts if they show signs of wear or damage. Proper belt tension is crucial for smooth operation.

- Storage: When not in use, store your lathe in a clean, dry environment to prevent rust and dust accumulation. Cover the lathe to protect it from dust and debris.

Safety Beyond the Basics: Advanced Safety Techniques for Experienced Users

As you progress in your lathe projects, consider incorporating these advanced safety techniques:

- Using Outboard Tools: Learn the safe use of outboard tools, such as steady rests and follower rests, to provide additional support and stability during specific turning operations.

- Dust Collection Systems: Implement a dust collection system on your lathe to minimize dust inhalation and maintain a clean work environment.

- Sharpening Techniques for Specific Tools: Mastering sharpening techniques for different lathe tools, like skew chisels and parting tools, ensures optimal cutting performance and reduces the risk of accidents.

- Advanced Workholding Techniques: With experience, explore advanced workholding techniques like chucking techniques and using centers for longer workpieces. Always prioritize safe and secure workpiece mounting.

The Future of Lathe Technology: Embracing Innovation

The realm of lathe technology is constantly evolving, introducing exciting advancements for woodworkers and metalworkers alike. Here’s a glimpse into what the future holds:

- CNC Lathes: Computer Numerical Control (CNC) lathes offer increased precision and automation for complex projects.

- Digital Readouts: Digital readouts provide real-time data on speed, feed rates, and tool positions, enhancing control and accuracy.

- Variable Speed Drives: Variable speed drives offer a wider range of speeds, allowing for optimal tool selection and efficient cutting across different materials.

- Safety Features: Advanced lathes may incorporate built-in safety features, such as automatic shut-off mechanisms in case of emergencies.

These advancements, along with continued exploration and innovation, promise to enhance the capabilities and safety of lathes, further empowering woodworkers and metalworkers to create their masterpieces.