Mastering the Art of Breaking Concrete with Hand Tools: Techniques, Tools, Safety, and Tips

In 2024, breaking concrete can be a daunting task, but with the right hand tools, techniques, and safety measures, it becomes a manageable project. Whether you are renovating, repairing, or redesigning a space, understanding how to effectively and safely break concrete is essential. How to break concrete with hand tools ? This comprehensive guide covers all aspects of breaking concrete with hand tools, ensuring that you can approach your project with confidence and skill.

Understanding the Basics

Why Break Concrete with Hand Tools?

Breaking concrete with hand tools might seem old-fashioned in the age of power tools, but there are several reasons why it remains a popular choice.

- Precision: Hand tools offer superior control, allowing for precision in tasks that require careful removal of concrete.

- Cost-effective: Hand tools are typically more affordable than power tools, making them accessible for DIY enthusiasts and small projects.

- Portability: They don’t require electricity, meaning you can use them anywhere without needing a power source.

- Safety: For beginners, hand tools can be safer to handle compared to heavy machinery.

Common Scenarios

Concrete breaking is necessary in various scenarios, such as:

- Home Renovations: Removing old patios, driveways, or basement floors.

- Repairs: Fixing broken or uneven slabs.

- Redesigning: Creating new paths, garden features, or flooring.

- Construction: Preparing areas for new foundations or installations.

Tools for Breaking Concrete

Essential Hand Tools

Several hand tools are indispensable for breaking concrete effectively.

- Sledgehammer: A heavy sledgehammer is a primary tool for breaking concrete. The weight and force allow you to break through even thick slabs.

- Cold Chisel: Used to score or weaken the concrete before breaking it down further with a hammer.

- Mason’s Hammer: Smaller and more precise than a sledgehammer, suitable for detailed work.

- Pry Bar or Crowbar: Essential for prying up broken pieces of concrete and securing leverage.

- Hand Guard and Gloves: Protecting your hands is crucial, so sturdy gloves and hand protection are required.

- Safety Glasses: Flying debris can cause serious injuries, making safety glasses non-negotiable.

Optional Tools for Efficiency

While the essential tools are sufficient for most projects, additional tools can enhance efficiency and ease.

- Concrete Saw: A manual concrete saw can help score concrete more efficiently.

- Pickaxe: Useful for initial breaking and prying before using a sledgehammer.

- Shovel: Helps in removing debris and clearing the work area.

Techniques for Breaking Concrete

Scoring and Weakening

Before swinging the sledgehammer, preparing the concrete makes the task easier.

- Mark Your Area: Use chalk to outline the area you want to break.

- Score the Concrete: Use a cold chisel and a mason’s hammer to score along the line. This creates a weak point where the concrete will break more easily.

- Start at the Edges: It’s often easier to start breaking at the edges and work your way inward.

Using the Sledgehammer

Swinging a sledgehammer effectively involves technique as much as strength.

- Stance and Grip: Stand with your feet shoulder-width apart. Grip the sledgehammer firmly with both hands.

- Strike with Precision: Aim each blow precisely. Start with lighter taps to further weaken the scored line, then follow with heavier strikes.

- Work in Sections: Break the concrete into manageable sections. Trying to break too large an area at once can be inefficient and exhausting.

Removing Broken Pieces

Efficient removal of broken pieces is crucial to maintaining a safe, organized work area.

- Use a Pry Bar: Insert the pry bar into the cracks and leverage pieces free.

- Shovel and Clear Debris: Use a shovel to remove smaller pieces and clear the work area regularly to avoid tripping hazards.

Safety Considerations

Personal Protective Equipment (PPE)

Safety should be your top priority when breaking concrete.

- Wear Thick Gloves: Protects your hands from blisters, cuts, and bruises.

- Safety Glasses: Essential to shield your eyes from flying debris.

- Sturdy Footwear: Wear steel-toed boots to protect your feet from falling debris.

- Ear Protection: If noise levels are high, use earplugs or earmuffs to protect your hearing.

Safe Working Habits

Adopting safe working habits can prevent accidents.

- Take Breaks: Regular breaks reduce fatigue, which can cause accidents.

- Stay Hydrated: Breaking concrete is physically demanding, so stay hydrated, especially in hot conditions.

- Use Tools Correctly: Always use tools as intended and maintain them in good condition.

- Be Aware of Your Surroundings: Keep your work area clear and be aware of other people and obstacles around you.

Emergency Preparedness

Accidents can happen, so be prepared.

- First Aid Kit: Keep a first aid kit nearby.

- Emergency Plan: Have a plan for what to do in case of an emergency, including the quickest way to contact emergency services.

Tips for Efficiency

Plan Your Work

A well-planned project is more likely to be successful.

- Clear the Area: Ensure the work area is clear of obstacles before starting.

- Gather Tools: Assemble all needed tools beforehand to avoid interruptions.

Leverage and Technique Over Strength

Relying on proper technique and leverage can make the job easier.

- Position Your Body: Use your body’s weight to increase power in your swings and prying.

- Pry Correctly: Use the length of the pry bar to your advantage by applying force at the far end.

Maintain Your Tools

Well-maintained tools perform better and last longer.

- Sharpen Blades: Regularly sharpen chisels and other cutting tools.

- Check for Wear: Inspect tools for wear and damage, replacing them if necessary.

Learn from Others

Observing and learning from others’ experiences can be invaluable.

- Watch Tutorials: Tutorials and videos can provide visual guides on techniques.

- Ask Professionals: If possible, get advice from professionals who have experience in breaking concrete.

Advanced Techniques with Hand Tools

Hand tools have been the cornerstone of craftsmanship for centuries. While many people may be familiar with basic hand tool usage, mastering advanced techniques can elevate your projects to new heights. Advanced hand tool techniques require a deeper understanding of the tools themselves, the materials you’re working with, and the methods to achieve precision and efficiency. This part explores various advanced techniques with hand tools, covering different types of tools, their applications, and essential safety measures.

Precision Cutting Techniques

Advanced Sawing Methods

Sawing is a fundamental skill, but mastering advanced techniques takes practice and knowledge.

Japanese Pull Saw Technique

Japanese pull saws cut on the pull stroke rather than the push stroke, allowing for more control and precision.

- Grip and Stance: Hold the saw handle firmly with your dominant hand and support the blade with your other hand. Position yourself so that the cut is aligned with your body.

- Controlled Motion: Use slow, deliberate pull strokes. Let the saw do the work and avoid applying too much pressure.

- Applications: Ideal for fine woodworking, cabinetry, and detailed joinery.

Coping Saw Mastery

A coping saw is perfect for intricate cuts and curves.

- Blade Tension: Ensure the blade is properly tensioned to prevent it from bending during cutting.

- Pivoting Technique: Use short, controlled strokes and pivot the saw around curves. Practice making tight corners by rotating your wrist.

- Applications: Useful for coping joints, scrollwork, and detailed fretwork.

Advanced Chiseling

Chisels are essential for shaping and detailing wood and other materials. Advanced chiseling ensures cleaner, more precise cuts.

Paring Technique

Paring involves removing thin shavings of wood to refine a surface or create a smooth finish.

- Sharp Blade: Ensure your chisel is razor-sharp. A sharper blade allows for more control and cleaner cuts.

- Controlled Pressure: Apply controlled, even pressure with your dominant hand while guiding the blade with your other hand.

- Applications: Perfect for fine woodworking, creating joinery, and refining edges.

Mortise and Tenon Chiseling

Creating mortise and tenon joints requires precision and skill.

- Layout: Mark the mortise and tenon locations accurately with a marking gauge or square.

- Mortising: Use a mortise chisel to remove material in small increments. Ensure the sides remain straight and the bottom flat.

- Tenoning: Use a sturdy bench and a sharp chisel to create clean, straight tenons that fit snugly into the mortise.

Advanced Sharpening Techniques

Maintaining Blades

A sharp blade is essential for effective hand tool usage. Advanced sharpening techniques ensure your tools remain in peak condition.

Honing Bevels

Honing creates a fine edge on chisels and plane irons.

- Honing Guide: Use a honing guide to maintain a consistent angle. This ensures an even, sharp edge.

- Sharpening Stone: Use progressively finer grit stones to create a razor-sharp bevel. Finish with a strop to polish the edge.

- Applications: Ensures precise cuts and extends the life of your tools.

Scary Sharp Method

A method that uses sandpaper mounted on a flat surface to achieve a mirror-like finish.

- Grit Progression: Start with coarse grit sandpaper and progress to finer grits. Use a flat surface, like a piece of glass or granite, to ensure even sharpening.

- Lubrication: Use water or honing oil to float away metal particles and achieve a smoother finish.

- Applications: Suitable for plane irons, chisels, and other flat-edged tools.

Sharpening Saws

Sharp saw teeth ensure efficient and clean cuts.

Filing Teeth

Regular filing maintains saw sharpness.

- Saw File: Use a triangular saw file that fits the size of your saw’s teeth.

- Consistent Angles: File each tooth at a consistent angle. Count strokes to maintain uniformity.

- Applications: Essential for maintaining crosscut and rip saws.

Setting Teeth

Setting adjusts the angle of the saw teeth to ensure a straighter cut.

- Saw Set Tool: Use a saw set to bend each tooth slightly outwards. Alternate teeth on each side for an even set.

- Applications: Prevents the saw from binding in the cut and ensures smoother operation.

Joint Creation and Assembly

Advanced Joinery Techniques

Mastering advanced joinery techniques ensures strong, precise, and aesthetically pleasing joints.

Dovetail Joints

Dovetail joints are known for their strength and beauty.

- Layout: Use a dovetail marker to mark your tails and pins accurately. Precision here is critical.

- Cutting and Fitting: Use a dovetail saw for straight, clean cuts. A coping saw helps remove waste. Test fit frequently and pare with a chisel to achieve a snug fit.

- Applications: Ideal for drawer construction, cabinetry, and fine furniture.

Box Joints

Box joints offer a strong, decorative joinery option.

- Jig Use: Create consistent box joints with a jig. Mark your wood accurately before cutting.

- Test Fits: Regularly test fit pieces to ensure a tight, precise joint.

- Applications: Common in box making, drawer construction, and decorative furniture.

Assembly Techniques

Proper assembly ensures your project remains strong and aligns correctly.

Gluing and Clamping

Proper gluing and clamping are essential for a strong, long-lasting bond.

- Glue Selection: Choose the appropriate glue for your material. Wood glue for wood, epoxy for mixed materials, etc.

- Clamping Pressure: Apply even clamping pressure to prevent distortion. Use cauls to distribute pressure evenly.

- Applications: Ensures joints remain strong and aligned, preventing movement over time.

Doweling

Doweling strengthens joints with reinforced wooden pegs.

- Accurate Drilling: Use a dowel jig to drill perfectly aligned holes.

- Dry Fit: Assemble the joint without glue first to ensure proper alignment.

- Applications: Adds strength to butt joints, miters, and edge-to-edge joins.

Surface Preparation and Finishing

Advanced Sanding Techniques

Sanding smooths surfaces and prepares them for finishing.

Progressive Grit Sanding

Using progressively finer grits achieves a smooth finish.

- Start Coarse: Begin with a coarse grit to remove large imperfections.

- Progress Gradually: Move to finer grits step-by-step, finishing with very fine grit.

- Applications: Prepares surfaces for staining, painting, or sealing.

Hand Sanding Details

Hand sanding reaches areas that machines can’t.

- Custom Shapes: Use custom-shaped sanding blocks to match the contours of your project.

- Detail Work: Focus on small areas and intricate details for a flawless finish.

- Applications: Essential for fine woodworking, curved surfaces, and detailed craftsmanship.

Finishing Techniques

Proper finishing enhances and protects your work.

Staining and Sealing

Staining adds color while sealing protects the surface.

- Test Areas: Test the stain on a scrap piece of wood to ensure the desired color.

- Even Application: Apply stain evenly with a brush or cloth, following the wood grain.

- Sealers: Use a sealer appropriate for your material to protect against moisture and wear.

- Applications: Enhances the appearance and durability of furniture, cabinetry, and woodwork.

Veneering

Adding veneer can transform ordinary wood into a high-end finish.

- Surface Prep: Smooth and clean the surface before applying veneer.

- Adhesive Selection: Use the right adhesive for your veneer and substrate.

- Pressing: Use a veneer press or clamps to ensure a smooth, even bond.

- Applications: Adds a high-end finish to furniture, cabinetry, and paneling.

Tool Maintenance and Safety

Maintenance Tips

Proper maintenance extends the life of your tools and ensures peak performance.

Cleaning and Oiling

Regular cleaning and oiling prevent rust and wear.

- Clean After Use: Wipe down tools after each use to remove dust and debris.

- Oil Metal Parts: Apply a light coat of oil to metal parts to prevent rust.

- Applications: Ensures tools remain in good working condition and prolongs their lifespan.

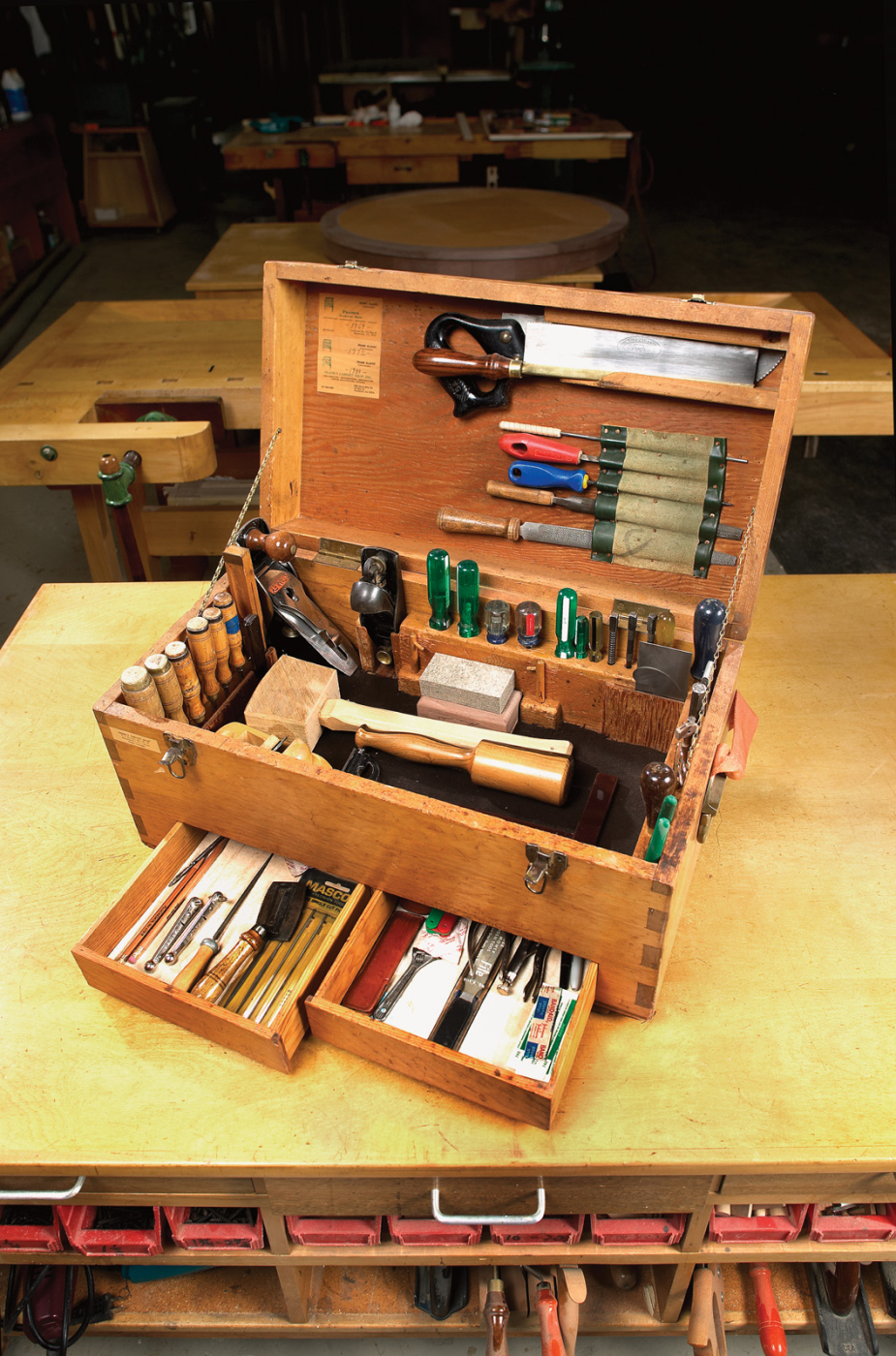

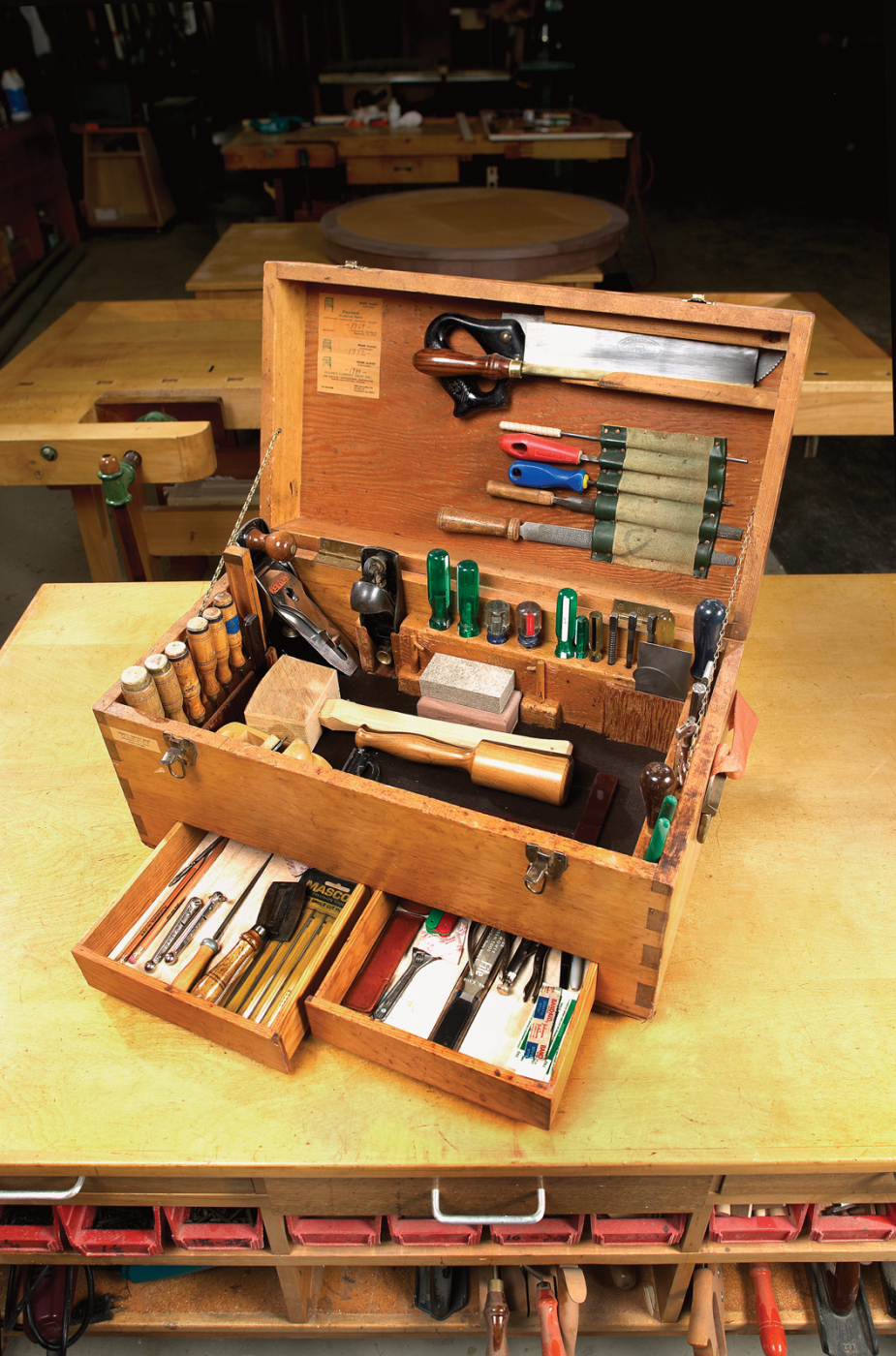

Storage Solutions

Proper storage prevents damage and prolongs tool life.

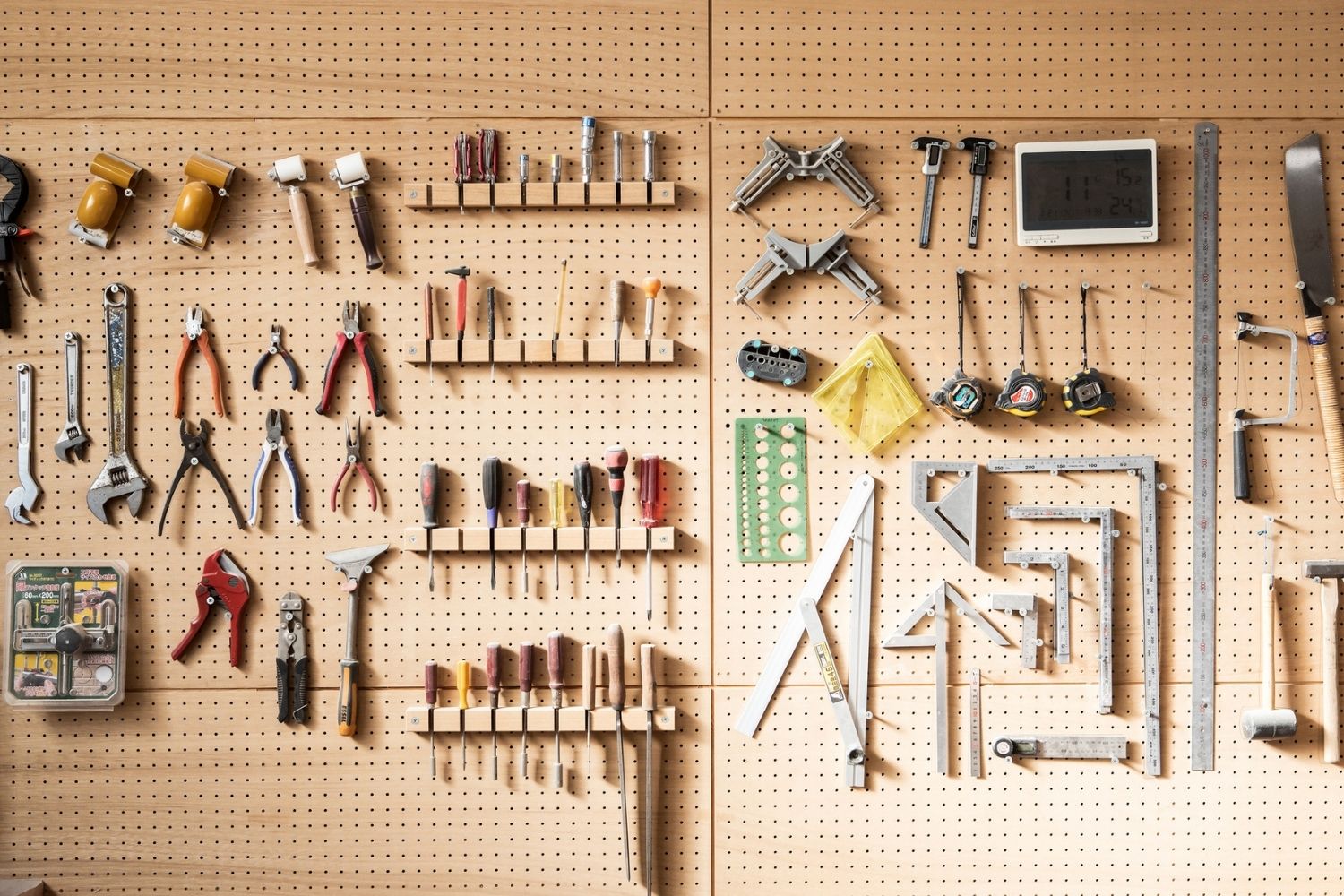

- Organized Storage: Use tool racks, pegboards, or tool chests to organize your tools.

- Controlled Environment: Store tools in a dry, climate-controlled environment to prevent rust and corrosion.

- Applications: Keeps tools organized, accessible, and in good condition.

Safety Measures

Advanced techniques often involve more complex and potentially hazardous procedures.

Proper PPE

Personal protective equipment (PPE) is essential.

- Safety Glasses: Always wear safety glasses to protect your eyes from debris.

- Hearing Protection: Use ear protection if you’re working in noisy environments.

- Gloves: Wear gloves to protect your hands from cuts and abrasions.

- Applications: Reducing the risk of injury and ensuring a safe working environment.

Safe Working Practices

Adopting safe work practices prevents accidents and injuries.

- Tool Inspection: Regularly inspect tools for damage or wear. Replace or repair as needed.

- Work Area: Keep your work area clean and organized to prevent tripping or accidents.

- Proper Techniques: Use tools as intended and follow manufacturer guidelines.

- Applications: Ensures a safe, efficient, and productive workspace.

Mastering advanced techniques with hand tools elevates your craftsmanship to professional levels. From precision cutting and advanced joinery to meticulous finishing and consistent maintenance, each aspect requires skill and attention to detail. Incorporating these advanced techniques into your work not only enhances the quality of your projects but also ensures safety and efficiency.

Investing time in learning and practicing these advanced techniques will pay off in the quality and durability of your work. Whether you’re a hobbyist or a professional, mastering the art of using hand tools is a rewarding journey that offers endless possibilities for creativity and craftsmanship.

Conclusion

Breaking concrete with hand tools is an art that combines strength, technique, and safety awareness. Mastering these aspects allows you to tackle a variety of projects effectively. From choosing the right tools to employing the best techniques and ensuring safety, every step matters in achieving a successful outcome.

By considering ergonomic practices, proper planning, and maintaining your tools, you can turn a challenging task into a manageable one. Whether you are a DIY enthusiast or a professional, understanding the intricacies of breaking concrete with hand tools will enhance your skill set and ensure your projects run smoothly and safely.

Exploring the World of Hand Tools: Definition, Types, Importance, and Advantages

Understanding Hand Tools

Hand tools are versatile and essential tools that are operated by hand, without the use of power. They are designed to assist in various tasks, ranging from simple DIY projects to professional construction work. Hand tools are typically made of durable materials such as steel or aluminum, and their design and functionality vary based on their specific purpose.

The range of hand tools available is vast and diverse, including tools such as hammers, screwdrivers, wrenches, pliers, and many more. Each hand tool serves a unique purpose and is designed to provide precision, control, and efficiency when working on specific tasks. Whether it’s tightening a bolt, driving a nail, or cutting through materials, hand tools offer the manual power necessary for these actions.

Types of Hand Tools

Hand tools encompass a wide variety of tools, each with its own distinct purpose and function. Some common types of hand tools include:

Cutting Tools: Examples include saws, utility knives, and scissors, which are designed for cutting through different materials.

Driving Tools: Screwdrivers, impact drivers, and nut drivers fall into this category, used for driving and tightening screws, bolts, and nuts.

Pliers and Wrenches: These tools provide grip and leverage, used for holding, twisting, or turning objects.

Striking Tools: Hammers, mallets, and axes are used for striking, driving, or breaking objects.

Measuring Tools: Tape measures, rulers, and levels are essential for accurate measurements and ensuring precise work.

Each type of hand tool has its own unique design and features, tailored to specific tasks and applications. Having a diverse collection of hand tools allows individuals to tackle different projects with ease and efficiency.

Importance of Hand Tools

Hand tools play a crucial role in various industries and everyday life. Their importance lies in their versatility, accessibility, and convenience. Here are some reasons why hand tools are essential:

Versatility: Hand tools can be used in a wide range of applications, making them highly versatile tools. They can be utilized for simple household repairs, woodworking, plumbing, electrical work, and more. Their adaptable nature makes them indispensable in many industries.

Accessibility: Hand tools are readily available and accessible to everyone. Whether it’s a homeowner, a professional tradesperson, or a DIY enthusiast, hand tools are essential for tackling projects of any scale. They are often affordable, allowing individuals to build their tool collection over time.

Precision and Control: Hand tools offer a level of precision and control that is sometimes difficult to achieve with power tools. Especially when working on delicate or intricate tasks, hand tools allow for greater finesse and accuracy, ensuring high-quality craftsmanship.

Advantages of Hand Tools

Hand tools provide several advantages that make them valuable assets in any toolkit:

Portability: Unlike power tools that require a power source, hand tools are portable and can be easily carried to various locations. This makes them ideal for on-the-go tasks or working in remote areas where access to electricity may be limited.

Safety: Hand tools generally have a lower risk of accidents compared to power tools. They do not rely on electrical or gas power, reducing the likelihood of electrical shocks or explosions. However, it is still crucial to use hand tools correctly and follow safety guidelines.

Skill Development: Working with hand tools allows individuals to develop essential skills such as hand-eye coordination, precision, and problem-solving abilities. These skills can be applied not only in specific tasks but also in other areas of life.

In conclusion, hand tools are versatile, essential tools that offer precision, control, and convenience. With various types available, they can be used for a wide range of applications. Hand tools are important for their versatility, accessibility, and the advantages they provide, including portability, safety, and skill development. Whether it’s a small repair at home or professional construction work, hand tools are indispensable in the world of craftsmanship and DIY projects.

Milwaukee Made in USA Hand Tools: Uncompromising Quality

Commitment to Quality

Milwaukee’s Made in USA hand tools are a testament to their unwavering commitment to quality. From the initial design phase to the manufacturing process, every step is meticulously executed to ensure that each tool meets the highest standards. Milwaukee understands the importance of producing reliable and durable tools that professionals and enthusiasts can rely on. By manufacturing their hand tools in the USA, Milwaukee has complete control over the production process, allowing them to maintain the highest level of quality and consistency.

The commitment to quality extends to the materials used in Milwaukee’s hand tools. They carefully select premium raw materials to ensure the durability and longevity of their products. The rigorous quality control measures implemented at every stage of production guarantee that only the finest hand tools reach the market. This dedication to excellence sets Milwaukee apart and solidifies their reputation as a brand that delivers uncompromising quality.

American Craftsmanship

Milwaukee takes great pride in their American craftsmanship. By manufacturing their hand tools in the USA, they support local communities and provide job opportunities for skilled workers. This commitment to American manufacturing not only ensures the highest quality but also contributes to the overall economic growth of the country.

Milwaukee’s American craftsmen and craftswomen bring years of experience and expertise to the production of each hand tool. Their attention to detail, precision, and passion for their craft are evident in the final product. By investing in American manufacturing, Milwaukee showcases their belief in the skills and capabilities of American workers, driving innovation and fostering a sense of pride in their hand tools.

Investing in Local Communities

By producing their hand tools in the USA, Milwaukee actively invests in local communities. Their manufacturing facilities create jobs and support the local economy. This investment not only benefits the workers directly employed by Milwaukee but also has a ripple effect throughout the community.

The presence of Milwaukee’s manufacturing facilities contributes to a stronger local supply chain. Local suppliers and vendors are given opportunities to collaborate with Milwaukee, further boosting economic growth in the area. Additionally, the jobs created by Milwaukee provide stability and a source of income for families, which in turn supports local businesses and services.

Environmental Responsibility

Milwaukee’s commitment to manufacturing their hand tools in the USA aligns with their dedication to environmental responsibility. By producing tools locally, they reduce the carbon footprint associated with transportation and minimize the environmental impact of their operations.

Manufacturing in the USA allows Milwaukee to implement sustainable practices more effectively. They can monitor and control their energy consumption, waste management, and recycling efforts more closely. Milwaukee’s commitment to environmental responsibility extends beyond their manufacturing process and into the design of their tools. They strive to create products that are more energy-efficient and environmentally conscious, further reducing their ecological footprint.

In conclusion, Milwaukee’s Made in USA hand tools embody uncompromising quality and American craftsmanship. By manufacturing their tools in the USA, Milwaukee demonstrates their commitment to delivering the highest level of quality and consistency. This commitment not only benefits customers by providing reliable and durable tools but also supports local communities and the American economy. Moreover, Milwaukee’s American manufacturing practices align with their environmental responsibility goals, reducing their carbon footprint and promoting sustainability. With Milwaukee Made in USA hand tools, professionals and enthusiasts can trust in the quality, craftsmanship, and environmental consciousness of their tools.

The Milwaukee Hand Tools Warranty: Unmatched Assurance, Reliability and Customer Satisfaction

Unparalleled Assurance:

Guaranteeing Customer Satisfaction

Milwaukee’s warranty program provides an exceptional level of assurance to customers. If any defects or malfunctions occur during normal use, Milwaukee pledges to repair or replace the tool, ensuring that customers can continue their work without interruptions. This guarantee of satisfaction demonstrates Milwaukee’s commitment to standing behind the quality and performance of their hand tools.

Customers can have peace of mind knowing that their investment in Milwaukee hand tools is protected. The warranty coverage extends for a specific period, typically ranging from one to five years, depending on the product. During this time, if any issues arise due to manufacturing defects or faulty materials, Milwaukee will stand behind their product and ensure that customers receive a fully functional and reliable tool. This unmatched assurance allows customers to rely on their Milwaukee hand tools with confidence, knowing that they are built to withstand the rigors of demanding worksites and heavy use.

Reliable Support:

Assistance at Every Step

In addition to repairs and replacements, Milwaukee offers reliable support to customers. Their team of knowledgeable professionals is readily available to provide assistance and support at every step of the process. Whether customers have questions, need troubleshooting advice, or require guidance on tool maintenance, Milwaukee’s customer support is there to help.

Milwaukee understands that customers may encounter challenges or need guidance to maximize the performance of their hand tools. With their commitment to customer satisfaction, Milwaukee’s support team is dedicated to ensuring that customers have a seamless experience. They can rely on the expertise and assistance provided by Milwaukee’s professionals, who can offer insights on using the tools effectively and efficiently, as well as provide recommendations for tool maintenance to prolong their lifespan.

Peace of Mind:

Trusting in Quality and Performance

The Milwaukee Hand Tools Warranty goes beyond just providing repairs and replacements. It offers customers peace of mind, knowing that their investment is backed by a trusted brand. Milwaukee’s commitment to excellence is evident in their stringent quality control processes, guaranteeing that each hand tool meets or exceeds industry standards.

By backing their hand tools with a comprehensive warranty, Milwaukee offers customers peace of mind. They can trust in the quality and performance of their Milwaukee hand tools, knowing that the brand stands behind their products. This peace of mind allows customers to focus on their tasks, whether they are professionals working on job sites or DIY enthusiasts completing projects in their own workshops.

Unmatched Customer Satisfaction:

A Reputation Built on Reliability

Milwaukee has built a long-standing reputation for manufacturing high-quality hand tools. Their warranty program is a testament to this reliability and dedication. It demonstrates their commitment to customer satisfaction and ensures that customers have a positive experience with their Milwaukee hand tools.

By offering an unmatched warranty, Milwaukee solidifies their reputation as a trusted brand in the hand tool industry. They understand the importance of reliability and durability in completing projects efficiently and effectively. With their unparalleled assurance, reliable support, peace of mind, and unmatched customer satisfaction, Milwaukee continues to be a top choice for professionals and DIY enthusiasts alike.

Unparalleled Assurance:

Guaranteeing Customer Satisfaction

Milwaukee’s warranty program provides an exceptional level of assurance to customers. If any defects or malfunctions occur during normal use, Milwaukee pledges to repair or replace the tool, ensuring that customers can continue their work without interruptions. This guarantee of satisfaction demonstrates Milwaukee’s commitment to standing behind the quality and performance of their hand tools.

Customers can have peace of mind knowing that their investment in Milwaukee hand tools is protected. The warranty coverage extends for a specific period, typically ranging from one to five years, depending on the product. During this time, if any issues arise due to manufacturing defects or faulty materials, Milwaukee will stand behind their product and ensure that customers receive a fully functional and reliable tool. This unmatched assurance allows customers to rely on their Milwaukee hand tools with confidence, knowing that they are built to withstand the rigors of demanding worksites and heavy use.

Reliable Support:

Assistance at Every Step

In addition to repairs and replacements, Milwaukee offers reliable support to customers. Their team of knowledgeable professionals is readily available to provide assistance and support at every step of the process. Whether customers have questions, need troubleshooting advice, or require guidance on tool maintenance, Milwaukee’s customer support is there to help.

Milwaukee understands that customers may encounter challenges or need guidance to maximize the performance of their hand tools. With their commitment to customer satisfaction, Milwaukee’s support team is dedicated to ensuring that customers have a seamless experience. They can rely on the expertise and assistance provided by Milwaukee’s professionals, who can offer insights on using the tools effectively and efficiently, as well as provide recommendations for tool maintenance to prolong their lifespan.

Peace of Mind:

Trusting in Quality and Performance

The Milwaukee Hand Tools Warranty goes beyond just providing repairs and replacements. It offers customers peace of mind, knowing that their investment is backed by a trusted brand. Milwaukee’s commitment to excellence is evident in their stringent quality control processes, guaranteeing that each hand tool meets or exceeds industry standards.

By backing their hand tools with a comprehensive warranty, Milwaukee offers customers peace of mind. They can trust in the quality and performance of their Milwaukee hand tools, knowing that the brand stands behind their products. This peace of mind allows customers to focus on their tasks, whether they are professionals working on job sites or DIY enthusiasts completing projects in their own workshops.

Conclusion:

The Milwaukee Hand Tools Warranty is a symbol of unmatched assurance, reliability, support, peace of mind, and customer satisfaction. With their commitment to quality and excellence, Milwaukee stands behind their hand tools, ensuring that customers can confidently invest in their products. The comprehensive warranty program guarantees repairs or replacements for any defects or malfunctions, providing unparalleled assurance.

Milwaukee’s reliable customer support further enhances the experience, offering assistance and guidance when needed. This level of support ensures that customers have a seamless experience and can maximize the performance of their Milwaukee hand tools. With the peace of mind that comes from trusting in Milwaukee’s quality and performance, customers can rely on their hand tools to tackle any task.

Exploring the Best Hand Tools Made in the USA: Quality, Craftsmanship, Durability, Innovation

Introduction:

When it comes to hand tools, those made in the USA have long been synonymous with quality, craftsmanship, durability, innovation, and excellent customer support. In this comprehensive passage, we will explore the key perspectives associated with the best hand tools made in the USA. We will delve into the significance, benefits, and characteristics that make these tools stand out in the market. By examining these perspectives, we can gain a deeper understanding of why hand tools made in the USA are highly regarded and sought after.

1. Quality:

Uncompromising Standards and Precision Engineering

Hand tools made in the USA are known for their exceptional quality. Manufacturers in the USA adhere to stringent quality control processes and standards to ensure that each tool meets or exceeds expectations. They prioritize precision engineering and pay meticulous attention to detail throughout the manufacturing process.

From the selection of high-quality materials to the precision machining and finishing, every step is carried out with utmost care. Manufacturers in the USA understand that the quality of a hand tool directly impacts its performance and longevity. By focusing on quality, these tools provide users with the confidence and assurance that they can rely on their tools to get the job done right.

In addition to the manufacturing process, hand tools made in the USA are often subjected to rigorous testing before they are released to the market. This ensures that they meet the highest standards of performance, durability, and safety. Manufacturers understand that their reputation depends on the quality of their products, and they take pride in delivering tools that consistently meet or exceed customer expectations.

2. Craftsmanship:

Skilled Artistry and Attention to Detail

Craftsmanship is a hallmark of hand tools made in the USA. Skilled artisans and craftsmen take pride in their work and exhibit a high level of expertise in creating these tools. Each tool is carefully crafted, often by hand, with a keen eye for detail and a commitment to excellence.

Hand tools made in the USA often incorporate traditional techniques that have been passed down through generations. These techniques, combined with modern manufacturing processes, result in tools that embody both heritage and innovation. The craftsmen who create these tools possess a deep understanding of the materials, design principles, and ergonomic considerations required to produce top-quality products.

The craftsmanship behind these tools ensures that they not only perform well but also possess a certain aesthetic appeal. The attention to detail is evident in the design, ergonomics, and finishing touches of these tools, making them a pleasure to use. Manufacturers in the USA understand that a well-crafted tool not only enhances productivity but also elevates the overall user experience.

3. Durability:

Built to Last and Withstand Heavy Use

Durability is a critical aspect of hand tools made in the USA. These tools are designed to withstand the rigors of heavy use and demanding work environments. Manufacturers in the USA understand the importance of creating tools that can endure challenging tasks without compromising their performance.

Hand tools made in the USA are often constructed using high-quality materials, such as hardened steel, which enhances their strength and resistance to wear and tear. These materials are carefully selected to ensure that they provide optimal performance and durability. The manufacturing processes employed ensure that the tools are robust and can withstand repeated use without losing their functionality.

Furthermore, manufacturers in the USA often subject their tools to rigorous testing and quality control measures to ensure their durability. They understand that their customers rely on their tools for their livelihoods and need tools that can withstand the demands of their work. By creating durable tools that can withstand heavy use, manufacturers in the USA provide peace of mind to users, knowing that their tools will not fail them when they need them the most.

4. Innovation:

Continuous Improvement and Adaptation to User Needs

Innovation is a driving force behind hand tools made in the USA. Manufacturers in the USA strive to stay at the forefront of industry advancements and technology. They continuously seek ways to improve their tools, incorporating innovative features and design elements that enhance performance, ergonomics, and user experience.

Through research and development, these manufacturers listen to user feedback and adapt their tools to meet evolving needs. They actively engage with professionals and enthusiasts in various industries to understand the challenges they face and develop solutions that address those challenges. This customer-centric approach ensures that hand tools made in the USA are not only technologically advanced but also practical and user-friendly.

Innovation in hand tools made in the USA goes beyond incorporating new features. It also involves improving existing designs and materials to optimize performance. Manufacturers invest in the latest technologies and manufacturing processes to create tools that are more efficient, lightweight, and versatile. By embracing new technologies and materials, these tools continue to push the boundaries of what is possible, enabling users to work more efficiently and effectively.

5. Support:

Exceptional Customer Service and Warranty Programs

Hand tools made in the USA are backed by exceptional customer support and warranty programs. Manufacturers understand the importance of standing behind their products and ensuring customer satisfaction.

When purchasing hand tools made in the USA, customers can expect prompt and knowledgeable customer service. Manufacturers are readily available to address any inquiries, provide technical support, and assist with any issues that may arise. They understand that a reliable and responsive customer support team is essential for building trust and maintaining a positive relationship with customers.

Additionally, these tools often come with robust warranty programs, showcasing the manufacturer’s confidence in their product’s quality and durability. Manufacturers in the USA understand that accidents or defects can occur, even with the highest quality hand tools. Therefore, they offer warranties that cover repairs or replacements for a specified period.

Conclusion:

Hand tools made in the USA are highly regarded for their quality, craftsmanship, durability, innovation, and customer support. These tools embody the values and principles that have become synonymous with American manufacturing excellence. By prioritizing quality, craftsmanship, durability, innovation, and customer support, manufacturers in the USA have created a reputation for producing some of the best hand tools in the market.

Essential Hand Tools List for Every DIY Enthusiast: Building, Repairing, and Creating

Introduction:

When it comes to tackling DIY projects, having a well-stocked toolbox is essential. While power tools often take the spotlight, a comprehensive hand tools list is equally important for various tasks, from simple repairs to intricate woodworking projects. In this guide, we will explore the essential hand tools that are indispensable for any DIY enthusiast. Whether you are a seasoned craftsman or just starting your DIY journey, this list will ensure that you have the necessary tools to confidently tackle any project.

Measuring and Marking Tools:

Precision and Accuracy at Your Fingertips

Accurate measurements and markings are the foundation of any successful DIY project. The hand tools list begins with a tape measure. A retractable tape measure with a sturdy locking mechanism and clear markings is a must-have tool for measuring length and distance. Whether you’re measuring the dimensions of a room or marking the position for a new piece of furniture, a tape measure will be your go-to tool.

Another essential tool is the combination square. This versatile tool features a ruler and a square, making it perfect for measuring angles and marking straight lines with precision. The combination square is indispensable for tasks such as checking the squareness of corners or marking cut lines on wood or metal.

For marking measurements on rough surfaces like wood or concrete, carpenter’s pencils are perfect. These flat-sided pencils are durable and designed for clear markings on various materials. They are easy to grip and won’t roll away when you set them down, ensuring accurate and consistent markings.

To mark straight lines over long distances, a chalk line is ideal. This tool consists of a string coated with chalk dust and a reel mechanism for easy deployment and retraction. By snapping the string against a surface, you can create temporary markings that can guide your cuts, installations, or other alignment tasks.

Cutting and Shaping Tools:

Cutting and Shaping Tools for Every Project

Cutting and shaping tools are essential for various DIY projects. The hand tools list includes a handsaw, which is versatile for cutting wood. Look for one with a comfortable grip and sharp teeth. Handsaws come in different sizes and tooth configurations, each suitable for specific tasks. From crosscut saws to rip saws and back saws, choose the one that best suits your needs.

A utility knife is indispensable for precision cutting, scoring materials, and opening packages. Look for one with retractable blades for safety and convenience. Utility knives often have replaceable blades, allowing you to maintain a sharp edge for clean and accurate cuts over time. Whether you’re trimming wallpaper, cutting through carpet, or scoring drywall, a utility knife is a handy tool to have by your side.

Chisels are another essential tool for cutting and shaping. They come in various sizes and types, such as beveled edge chisels, mortise chisels, and paring chisels. Chisels are perfect for removing waste material, creating clean and precise joints, or shaping wood. They require sharpening and proper handling to maintain their effectiveness.

For intricate cuts and curves, a coping saw allows for precise control and flexibility. Its thin, replaceable blades can be maneuvered through tight spaces and allow for intricate and detailed cuts. Coping saws are commonly used in woodworking projects, especially for cutting out intricate shapes or making decorative cuts.

A file set is essential for smoothing rough edges, shaping metal, or fine-tuning woodworking projects. Files come in various shapes and sizes, each designed for specific tasks. From flat files to round files, half-round files, and needle files, there’s a file for every shaping and finishing need. These tools are perfect for removing burrs, refining edges, or achieving the desired shape and smoothness in your workpieces.

Fastening Tools:

Essential Tools for Secure Connections

Securing materials together is crucial for any DIY project. The hand tools list includes screwdrivers, both flathead and Phillips head, in various sizes to cover most screw applications. Screwdrivers are essential for driving screws into wood, metal, or other materials. Look for screwdrivers with comfortable handles and magnetic tips for easy handling and improved control.

A claw hammer is a classic tool for driving nails and removing them. Look for one with a comfortable grip and balanced weight. A hammer with a smooth face is ideal for driving nails without marring the surface, while the claw on the opposite end allows for easy nail removal. Whether you’re framing a wall, building furniture, or hanging pictures, a claw hammer will be your trusted companion.

A staple gun is versatile for upholstery projects or securing fabric. It allows for quick and efficient fastening of materials, such as fabric, insulation, or thin wood panels. Electric or pneumatic staple guns are available for heavy-duty applications, while manual staple guns are suitable for lighter tasks. Ensure you choose the right staples for your specific project, as different materials and thicknesses may require different staple sizes.

C-clamps are indispensable for holding objects together while glue dries or for securing materials during cutting or drilling. They come in a variety of sizes and clamping capacities, allowing you to hold different-sized objects securely in place. C-clamps are commonly used in woodworking, metalworking, and even during home improvement projects. Whether you’re gluing two pieces of wood together or need to hold a workpiece steady while you make precise cuts, C-clamps are a reliable choice.

Pliers are versatile tools for gripping, twisting, or cutting wires, as well as holding objects firmly in place. They come in various types, such as needle-nose pliers, slip-joint pliers, and locking pliers. Needle-nose pliers are ideal for tight spaces or intricate work, while slip-joint pliers offer adjustable jaw positions for different-sized objects. Locking pliers, also known as Vise-Grips, have a locking mechanism that allows them to clamp onto materials and hold them securely. Pliers are invaluable for tasks like bending wires, pulling nails, or gripping and turning objects.

Shaping and Finishing Tools:

Essential Tools for a Polished Finish

To refine your DIY projects and achieve a professional-looking finish, the hand tools list includes sanding blocks and sandpaper for smoothing surfaces and removing imperfections. Sanding blocks provide a stable surface for sandpaper, allowing you to apply even pressure and achieve consistent results. Sandpaper comes in various grits, ranging from coarse to fine. Coarser grits are suitable for removing material quickly or smoothing rough surfaces, while finer grits are ideal for achieving a smooth finish and preparing surfaces for painting or staining.

Planes are used to shave off thin layers of wood, creating smooth, even surfaces. They are commonly used in woodworking to remove rough spots, level joints, or shape edges. Planes come in different types, such as block planes, bench planes, and shoulder planes, each designed for specific applications. Ensure that you keep the blade of your plane sharp for optimal performance.

Rasps and files are perfect for shaping wood or removing excess material. They come in various shapes and coarseness, allowing you to refine curves, smooth rough edges, or create intricate designs. Rasps have larger teeth and are more aggressive, while files have finer teeth and are better suited for smoothing and finishing. Whether you’re working on a woodworking project or shaping metal, having a set of rasps and files in different sizes and shapes will be invaluable.

Wire brushes are ideal for removing rust, paint, or dirt from surfaces. They come in various types, such as wire hand brushes and wire cup brushes, each suited for different applications. Wire hand brushes are perfect for smaller areas or tight spaces, while wire cup brushes can be attached to power tools for faster and more efficient cleaning. Wire brushes are often used when preparing surfaces for painting or when restoring old tools and equipment.

Paintbrushes and rollers are essential for applying paint or finishes. Choose a variety of brush sizes and roller types based on project requirements. Paintbrushes come in different bristle materials, such as natural or synthetic, each offering different performance characteristics. Rollers are available in various sizes and nap lengths, allowing you to achieve different textures and finishes. Ensure that you clean your brushes and rollers thoroughly after each use to extend their lifespan and maintain their performance.

Conclusion:

A well-equipped toolbox filled with the essential hand tools from this comprehensive list is a DIY enthusiast’s best friend. Each tool plays a crucial role in different stages of a project, ensuring accuracy, precision, and a professional finish. Remember to invest in high-quality tools and familiarize yourself with proper usage. With your toolbox filled with these essential hand tools, you’ll be well-prepared to confidently tackle any DIY project that comes your way. Whether you’re measuring, cutting, fastening, shaping, or finishing, the right hand tools will make your projects efficient, enjoyable, and successful. So, equip yourself with these essential tools and let your creativity and skills shine as you embark on your DIY adventures.

Dirty Hand Tools: Rugged, Reliable, and Built to Tackle the Toughest Jobs

Unparalleled Durability and Construction

Heavy-Duty Materials for Long-Lasting Performance

Dirty Hand Tools, a renowned brand in the industry, is known for producing tools that are built to last. With a strong commitment to quality and durability, their products are designed to withstand the most demanding conditions. The company uses heavy-duty materials and employs solid construction techniques to ensure that their tools can handle frequent use and tough jobs without compromising performance. From power tools to outdoor equipment, Dirty Hand Tools offers a comprehensive range of rugged tools that can withstand the test of time and provide exceptional results.

When it comes to durability, Dirty Hand Tools is unmatched. Their tools are engineered with robust components and reinforced structures to withstand heavy usage and extreme conditions. For instance, their chainsaws are constructed with high-quality materials that can endure the rigors of cutting through dense wood. Their log splitters are built with sturdy frames and powerful hydraulic systems that can effortlessly split even the toughest logs. These durable tools are designed to be reliable workhorses, ensuring that users can confidently tackle any task at hand.

Reliability in Any Environment

Engineered to Perform in Extreme Conditions

Dirty Hand Tools understands the importance of reliability when it comes to tackling tough jobs. Their products are engineered to deliver consistent performance, regardless of the environment. Whether you’re working in scorching heat, freezing cold, or wet conditions, Dirty Hand Tools’ tools are designed to keep performing at their best. With high-quality components and advanced engineering, these tools are built to withstand the challenges of any job site. Professionals and homeowners alike can rely on Dirty Hand Tools to deliver unbeatable performance, no matter the conditions.

To ensure reliability, Dirty Hand Tools conducts rigorous testing and quality control measures at every stage of the manufacturing process. From the selection of materials to the final assembly, each tool undergoes stringent checks to ensure it meets the brand’s high standards. This meticulous attention to detail ensures that every Dirty Hand Tools product performs reliably, providing peace of mind to users who depend on their tools day in and day out.

A Wide Range of Tools for Every Job

From Cutting to Clearing, We Have You Covered

Dirty Hand Tools recognizes that different jobs require different tools. That’s why they offer a comprehensive range of products to cater to various needs, whether you’re a professional tradesperson or a dedicated homeowner. Their diverse lineup includes power tools such as chainsaws, log splitters, pressure washers, and generators, designed to tackle demanding tasks efficiently and effectively.

For outdoor enthusiasts and homeowners, Dirty Hand Tools provides a wide array of equipment to handle landscaping and maintenance tasks. Their lineup includes lawn mowers, wood chippers, edgers, and more, all designed to make outdoor projects easier and more efficient. With features like adjustable cutting heights, ergonomic handles, and powerful engines, Dirty Hand Tools ensures that users can achieve professional-level results in their own backyard.

User-Friendly Design for Enhanced Performance

Comfort and Control for Effortless Operation

Dirty Hand Tools understands that comfort and ease of use are essential for maximum performance. With a strong emphasis on ergonomic design, their tools are built to be user-friendly and comfortable to operate. The brand incorporates features such as cushioned handles, adjustable grips, and well-placed controls to enhance the overall user experience.

Comfortable and well-designed tools not only improve efficiency but also reduce the risk of fatigue and injury. Dirty Hand Tools prioritizes user safety by minimizing hand strain and discomfort, enabling users to tackle tough jobs for extended periods without compromising their well-being. The brand’s commitment to user-centric design ensures that their tools not only get the job done efficiently but also contribute to a pleasant and productive working experience.

Safety First

Protecting Users and Promoting Peace of Mind

Dirty Hand Tools places a strong emphasis on safety, recognizing that accidents can happen even in the most controlled environments. Their products are designed with multiple safety features to protect both the user and the tool itself. For example, their chainsaws are equipped with chain brakes and kickback protection systems that instantly halt the chain’s movement in case of a kickback. Additionally, their log splitters have built-in shields to protect users from flying debris during the splitting process.

These safety features are integral to the design of Dirty Hand Tools’ products, providing users with peace of mind and reducing the risk of accidents. By prioritizing safety, Dirty Hand Tools ensures that their tools can be used with confidence, enabling users to focus on the task at hand without unnecessary concerns about their well-being.

Exceptional Customer Service

Going Above and Beyond for Customer Satisfaction

Dirty Hand Tools is committed to providing exceptional customer service, further enhancing their reputation as a trusted brand. They stand behind the quality of their products by offering comprehensive warranties, ensuring customer satisfaction and peace of mind. In case of any issues or inquiries, their dedicated support team is readily available to assist and provide technical support, offering a hassle-free experience to customers.

Moreover, Dirty Hand Tools values customer feedback and continually strives to improve and innovate based on their input. By actively listening to their customers, the brand ensures that their products meet the evolving needs and expectations of users. This customer centric approach creates a strong bond between Dirty Hand Tools and its customer base, fostering long-lasting relationships built on trust and satisfaction.

Dirty Hand Tools’ commitment to exceptional customer service is evident in their efficient and reliable distribution network. They work closely with authorized dealers and retailers to ensure that their products are readily available to customers, both online and in brick-and-mortar stores. This ensures that customers can easily access the tools they need, backed by the support and expertise of knowledgeable professionals.

In Conclusion

In addition to their extensive range of tools, Dirty Hand Tools also offers a variety of accessories and replacement parts to enhance the functionality and longevity of their products. From chainsaw chains and log splitter wedges to mower blades and pressure washer nozzles, customers can find everything they need to keep their Dirty Hand Tools in optimal condition. By providing these accessories and parts, Dirty Hand Tools demonstrates their commitment to delivering a comprehensive solution for all their customers’ needs.

Dirty Hand Tools also recognizes the importance of sustainability and environmental responsibility. They actively work to minimize their carbon footprint and promote sustainable practices throughout their operations. From using energy-efficient manufacturing processes to sourcing materials from responsible suppliers, Dirty Hand Tools considers the environmental impact of their products and strives to reduce it wherever possible. This commitment to sustainability aligns with the growing demand for eco-friendly solutions and further solidifies Dirty Hand Tools’ position as a socially and environmentally responsible brand.

Furthermore, Dirty Hand Tools understands the value of ongoing innovation. They invest in research and development to continuously improve their products and introduce new technologies that enhance performance and efficiency. By staying at the forefront of advancements in the industry, Dirty Hand Tools ensures that their customers have access to the latest tools and features, enabling them to tackle even the toughest jobs with ease.

Klein Hand Tools: The Epitome of Quality, Precision, Reliability, and Versatility

Introduction:

Klein Hand Tools have emerged as the industry standard for excellence in the realm of hand tools. With a rich history spanning over a century, Klein has established itself as a trusted and respected brand known for its unwavering commitment to producing tools of the highest quality, precision, reliability, and versatility. Professionals and enthusiasts from various industries have come to rely on Klein Hand Tools to deliver superior performance and exceptional results. In this passage, we will delve into the key aspects that contribute to the enduring success of Klein Hand Tools, highlighting their dedication to quality, precision, reliability, and versatility.

Quality –

Exceeding Expectations through Superior Craftsmanship

At the core of Klein Hand Tools is an unwavering commitment to quality that sets them apart from their competitors. Klein painstakingly selects top-grade materials and employs skilled artisans who possess a keen attention to detail. This meticulous approach ensures that every tool produced by Klein meets and exceeds the highest standards of quality. Each tool undergoes rigorous testing and inspection to guarantee its durability, longevity, and exceptional performance. Professionals who choose Klein Hand Tools can be confident that they are investing in instruments that will withstand the test of time and consistently deliver outstanding results.

Klein Hand Tools exemplify the epitome of quality in every aspect of their design and manufacturing process. By using only the finest materials, Klein ensures the longevity and durability of their tools. With skilled craftsmen at the helm of production, each tool is meticulously created and refined to meet the highest standards of quality. Additionally, Klein Hand Tools undergo stringent testing procedures to ensure they can withstand the demands of professionals across various industries. This unwavering commitment to quality not only differentiates Klein from its competitors but also instills a sense of confidence among users, knowing they have chosen tools that will consistently perform at an exceptional level.

Precision –

Achieving Unparalleled Accuracy and Perfection

Precision is paramount when it comes to hand tools, and Klein Hand Tools excel in this aspect. The company recognizes the importance of accuracy in a multitude of tasks and has engineered their tools to deliver unparalleled precision. Each tool is meticulously designed and calibrated to ensure optimal performance. Klein’s precision-engineered cutting edges, finely-tuned measuring mechanisms, and ergonomic designs all contribute to their ability to consistently deliver precise results. By prioritizing precision, Klein empowers professionals to achieve excellence in their work, resulting in increased productivity and customer satisfaction.

Klein Hand Tools are renowned for their precision, which is evident in every aspect of their design and functionality. Whether it’s a cutting tool or a measuring instrument, Klein ensures that each tool is meticulously calibrated and tested to deliver accurate results consistently. This commitment to precision has made Klein Hand Tools the trusted choice of professionals in fields such as electrical work, plumbing, and carpentry. By providing tools that prioritize accuracy, Klein Hand Tools enable professionals to execute their tasks with confidence, knowing that their tools will consistently deliver precise and reliable results.

Reliability –

Tools You Can Depend on for Consistent Performance

Reliability is a perspective that resonates strongly with users of Klein Hand Tools. Professionals understand the significance of having tools they can rely on to complete tasks efficiently and effectively. Klein Hand Tools are meticulously engineered and rigorously tested to withstand demanding work environments. The company’s commitment to reliability ensures that professionals can trust Klein Hand Tools to consistently deliver exceptional results, avoiding costly delays and mistakes. With Klein Hand Tools, professionals can have peace of mind, knowing they have tools they can depend on to get the job done.

Klein Hand Tools are synonymous with reliability, earning the trust of professionals across various industries and trades. Klein’s dedication to reliability is evident in their rigorous testing procedures, ensuring that each tool can withstand the demands of the job. Impact tests, endurance tests, and rigorous quality checks are just a few of the measures Klein Hand Tools undergo to guarantee their durability and reliability. By choosing Klein, professionals can be confident that their tools will perform consistently, enabling them to complete their tasks efficiently and effectively, without the fear of tool failure.

Versatility –

A Comprehensive Solution for Every Task

Klein Hand Tools‘ versatility further solidifies their position as the industry leader. The company offers a diverse range of tools, catering to the unique requirements of different industries and applications. Whether it’s electrical work, plumbing installations, or general maintenance tasks, Klein provides specialized tools designed to meet the specific needs of each trade. This versatility allows professionals to rely on Klein Hand Tools as a comprehensive solution for their tool needs. By offering a vast selection of tools, Klein ensures that users can find the perfect instrument to tackle any task they encounter.

Klein Hand Tools not only provide a diverse range of tools but also prioritize user-friendly features that enhance versatility. Ergonomic handles, interchangeable components, and adjustable mechanisms are just a few examples of the thoughtful design elements that make Klein Hand Tools adaptable to a wide range of tasks and working conditions. This versatility allows professionals to streamline their toolset and eliminates the need for multiple specialized tools. Whether it’s a multi-purpose tool that combines several functions into one or a tool with adjustable settings to accommodate different tasks, Klein Hand Tools provide a comprehensive solution that saves time, space, and effort. This versatility ensures that professionals can rely on Klein Hand Tools to tackle any task that comes their way, making them a trusted and indispensable companion in the workshop or job site.

Innovation –

Staying Ahead of Evolving Needs and Technologies

Innovation serves as a driving force behind Klein Hand Tools’ continued success. The company recognizes the importance of staying ahead of evolving needs and emerging technologies within various industries. Klein invests in research and development to create new tools and improve existing ones, ensuring that their product line remains relevant and adaptable to the changing demands of professionals. By actively seeking ways to enhance performance, efficiency, and safety, Klein Hand Tools continue to be at the forefront of innovation in the hand tool industry.

Klein Hand Tools’ commitment to innovation is evident in their constant pursuit of improved designs and functionalities. The company collaborates with industry professionals and experts to understand emerging trends and challenges, enabling them to develop tools that address specific needs. Whether it’s integrating new materials for enhanced durability, implementing advanced ergonomics for improved user comfort, or incorporating cutting-edge technologies for increased efficiency, Klein Hand Tools consistently push the boundaries of innovation. Professionals who choose Klein can be confident that they are equipping themselves with tools that incorporate the latest advancements in the industry.

Customer Satisfaction –

Building Relationships Based on Trust

Customer satisfaction is at the core of Klein Hand Tools’ ethos. The company understands that building strong relationships with their customers is essential for long-term success. Klein Hand Tools not only prioritize excellence in their products but also provide exceptional customer service. From providing informative product guides and tutorials to offering prompt assistance with inquiries and warranty claims, Klein ensures that their customers are supported throughout their tool ownership journey. By prioritizing customer satisfaction, Klein Hand Tools foster a loyal customer base, creating a community of professionals who trust and endorse their products.

Klein Hand Tools’ commitment to customer satisfaction extends beyond the sale of their tools. The company understands that professionals rely on their tools daily and may encounter issues or have questions. As such, Klein provides comprehensive customer support, allowing users to seek assistance whenever needed. Whether it’s troubleshooting, repairs, or inquiries about tool usage, Klein’s dedicated support team is readily available to address customer concerns. This commitment to excellent customer service further strengthens the trust and loyalty that professionals place in Klein Hand Tools.

Conclusion:

Klein Hand Tools have rightfully earned their reputation as the epitome of quality, precision, reliability, and versatility in the hand tool industry. From their unwavering commitment to producing tools of exceptional quality to their precision-engineered designs that deliver accurate results, Klein Hand Tools consistently exceed the expectations of professionals across various trades. With reliability ingrained in their manufacturing process and an extensive range of versatile tools, Klein ensures that professionals have the tools they can depend on for consistent performance in any task. Through their dedication to innovation and customer satisfaction, Klein Hand Tools continue to lead the industry, adapting to evolving needs and technologies while building lasting relationships with their user base. To put it simply, Klein Hand Tools are a testament to the pursuit of excellence and the embodiment of trust for professionals who demand the best in their tools.

Hand Tools Safety: Exploring Perspectives on Awareness, Proper Usage, Personal Protective Equipment

Introduction:

Hand tool safety is of paramount importance in any work environment or DIY project. Accidents and injuries can be prevented by taking the necessary precautions and following best practices. In this comprehensive passage, we will explore the topic of hand tool safety from five distinct perspectives: awareness, proper usage, personal protective equipment (PPE), maintenance, and training. By examining these perspectives, we can gain a deeper understanding of the significance, benefits, and best practices associated with ensuring hand tool safety.

1. Awareness:

Recognizing Hazards to Prevent Accidents

The importance of awareness cannot be overstated when it comes to hand tool safety. Being aware of potential hazards associated with hand tools is crucial for preventing accidents. It involves recognizing potential dangers and taking proactive measures to mitigate risks.

Promoting a culture of awareness is vital in creating a safe work environment. Individuals should be encouraged to identify and report potential hazards, such as slippery surfaces, sharp edges, or unstable materials. Regular inspections of tools, workspaces, and surrounding areas can help identify potential risks. By being aware of potential hazards, individuals can take appropriate measures to prevent accidents and maintain a safe working environment.

Awareness also extends to understanding the limitations of hand tools. Each tool has its own specifications and intended use. Using a tool inappropriately or for tasks it is not designed for can lead to accidents and injuries. Individuals must be aware of the proper tool for each job and use it accordingly.

Another crucial aspect of awareness is understanding the importance of focus and concentration while using hand tools. Distractions can lead to mistakes and accidents. By being fully present and attentive to the task at hand, individuals can minimize the risk of errors and injuries.

2. Proper Usage:

Following Guidelines for Safe Operation

The proper usage of hand tools is essential for maintaining a safe work environment. Each hand tool is designed for specific tasks and has its limitations. Understanding the intended purpose and following manufacturer’s guidelines is key to preventing accidents and injuries.

Individuals should familiarize themselves with the correct operation and handling of each hand tool they use. This involves reading and understanding the tool’s instruction manual, safety guidelines, and any specific warnings. Using hand tools inappropriately or for tasks they are not designed for can lead to accidents and tool failure. Adhering to proper usage guidelines ensures the safe and efficient operation of hand tools.

It is also important to consider the ergonomics of using hand tools. Improper ergonomics can lead to muscle strain, fatigue, and repetitive strain injuries. Individuals should learn and apply the proper techniques for holding and using hand tools to minimize the risk of physical discomfort or long-term injuries.

Proper usage also encompasses taking precautions when using power tools. Power tools can be more dangerous than manual hand tools due to their higher speed and power. Understanding how to safely operate and control power tools is essential to prevent accidents and injuries.

3. Personal Protective Equipment (PPE):

Ensuring Worker Safety

The use of personal protective equipment (PPE) is crucial for hand tool safety. PPE helps protect individuals from potential hazards, such as flying debris, sharp edges, or chemical exposure. Employers have a responsibility to provide the necessary PPE to workers and ensure that it is properly fitted and in good condition.

Common PPE items for hand tool safety include safety glasses, gloves, hearing protection, and steel-toed boots. The specific PPE required may vary depending on the tasks performed and the potential hazards present. It is essential for workers to understand the importance of wearing PPE consistently and to be vigilant in its use. Wearing the appropriate PPE not only reduces the risk of injuries but also promotes a safety-conscious culture in the workplace.

Safety glasses are essential for protecting the eyes from debris, dust, or sparks that may be generated while using hand tools. Gloves provide hand protection and improve grip when handling tools, reducing the risk of cuts or abrasions. Hearing protection, such as earplugs or earmuffs, should be used in loud environments to prevent hearing damage. Steel-toed boots provide foot protection from falling objects or accidental impacts.

Proper fitting and maintenance of PPE is crucial for its effectiveness. PPE should fit comfortably and securely without impairing movement or functionality. Regular inspections should be conducted to ensure that PPE is in good condition, and any damaged or worn-out items should be replaced immediately.

4. Maintenance:

Keeping Tools in Safe Working Condition

Regular maintenance of hand tools is crucial for ensuring their safe operation. Tools that are worn, damaged, or defective can pose significant risks to users. Regular inspections and maintenance help identify potential hazards before they lead to accidents.

Individuals should routinely check their hand tools for signs of wear, damage, or defects. This includes inspecting handles for cracks or splinters, checking cutting edges for dullness or chips, and verifying that adjustable parts are functioning correctly. Any damaged or malfunctioning tools should be immediately removed from service and either repaired or replaced.

Proper tool storage is also an important aspect of maintenance. Tools should be stored in designated areas, secured to prevent falling, and protected from exposure to moisture, extreme temperatures, or corrosive substances. The storage area should be clean and organized, allowing easy access to tools while minimizing the risk of accidental contact or damage.

Regular cleaning and lubrication of tools can also prolong their lifespan and ensure safe operation. Cleaning tools after use helps remove debris and buildup that can affect their functionality. Lubricating moving parts, such as hinges or joints, reduces friction and allows for smooth operation. Additionally, rust prevention measures should be taken, especially for tools that may come into contact with moisture.

Individuals should also be aware of the proper disposal of damaged or broken tools. These tools should not be used or stored, as they can pose a safety risk. Additionally, they should be disposed of following appropriate regulations and guidelines to minimize environmental impact.

5. Training:

Providing Education and Skill Development

Comprehensive training programs are essential for ensuring safe hand tool usage. Proper training educates workers and DIY enthusiasts on correct tool handling, safety procedures, and risk mitigation strategies. It empowers individuals with the knowledge and skills necessary to work safely and prevent accidents.

Training should cover various aspects of hand tool safety, including hazard identification, safe work practices, emergency response, and the proper use of PPE. The content of the training should be tailored to the specific tasks and tools individuals will be working with. Employers should invest in ongoing training to keep workers updated on new tools, technologies, and safety regulations.

Training programs should not only focus on theoretical knowledge but also include practical exercises that allow individuals to apply their skills in a controlled environment. Hands-on training sessions can simulate real-life work scenarios, allowing individuals to practice using tools safely and efficiently. Regular refresher courses and assessments can help reinforce hand tool safety practices and ensure that individuals stay up to date with best practices.

Furthermore, training should emphasize the importance of communication and teamwork in maintaining a safe work environment. Encouraging open dialogue and collaboration among team members promotes a safety-conscious culture, where everyone looks out for each other’s well-being. Training sessions could include role-playing exercises or group discussions to enhance communication skills related to hand tool safety.

Conclusion:

Hand tool safety is a critical aspect of any work environment or DIY project. By considering the perspectives of awareness, proper usage, personal protective equipment, maintenance, and training, individuals can create a comprehensive approach to hand tool safety. Raising awareness of potential hazards, following proper usage guidelines, wearing appropriate PPE, conducting regular maintenance, and providing comprehensive training are all key elements in ensuring hand tool safety.

A culture of safety, combined with proper education and training, is crucial for preventing accidents and injuries. Employers and individuals must prioritize hand tool safety and take proactive measures to minimize risks. By implementing the practices discussed in this passage, individuals can work confidently and efficiently, knowing that their well-being is protected. Hand tool safety is not only about personal protection but also about creating a safe and productive work environment for everyone involved.

Hand Tools on Essentiality, Versatility, Expertise, Safety, and Technological Advancements

Introduction: