The Machinist Tool Box: Organization, Efficiency, Craftsmanship

Part 1: Introduction to Machinist Tool Boxes – The Backbone of Precision Work

Level 1: What Is a Machinist Tool Box?

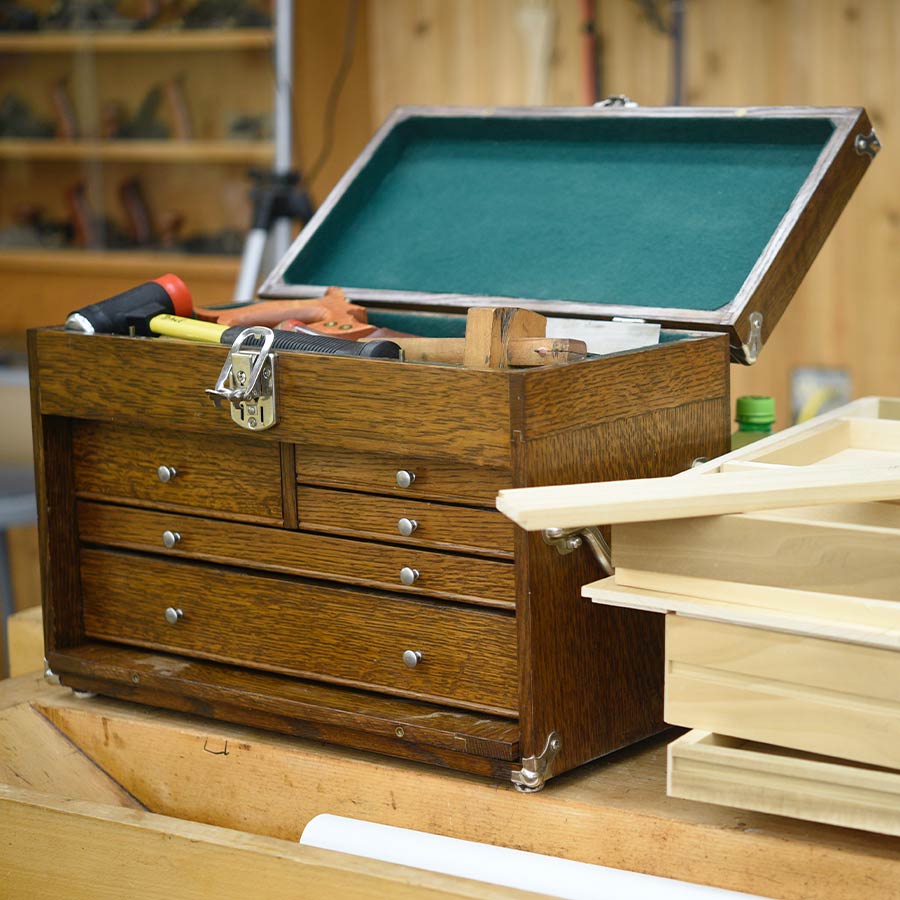

A machinist tool box is a specialized storage solution designed to house the tools, instruments, and accessories essential for machining operations. These boxes are crafted with precision in mind, offering durable construction, organized compartments, and portability to meet the needs of professional machinists, hobbyists, and tradespeople alike. From wrenches and calipers to drill bits and files, a machinist tool box ensures that every tool has its place, promoting efficiency and minimizing clutter.

- The Role of Machinist Tool Boxes in Precision Work:

Machining requires meticulous attention to detail, and having the right tools readily accessible is crucial for maintaining accuracy and productivity. A well-organized machinist tool box not only protects valuable equipment but also streamlines workflows by reducing the time spent searching for specific tools. This makes it an indispensable asset in workshops, factories, and even on-the-go repair jobs. - Why Invest in a Quality Machinist Tool Box?

For machinists, investing in a high-quality tool box is as important as acquiring the tools themselves. A sturdy, thoughtfully designed tool box safeguards expensive instruments from damage, extends their lifespan, and enhances overall job performance. Whether you’re working on intricate metalwork or heavy-duty fabrication, a reliable tool box ensures your workspace remains efficient and professional.

Level 2: Key Features of Machinist Tool Boxes

Understanding what sets machinist tool boxes apart highlights their value in both personal and professional settings.

- Material Durability and Construction:

Most machinist tool boxes are made from robust materials like steel, aluminum, or impact-resistant polymers. Steel models offer superior strength and security, while aluminum provides lightweight portability without sacrificing durability. Polymer-based options are often corrosion-resistant, making them ideal for harsh environments. - Customizable Storage Solutions:

One of the standout features of machinist tool boxes is their ability to adapt to individual needs. Many models come with adjustable dividers, removable trays, and specialized compartments for organizing small parts, delicate instruments, and larger tools. Some even include locking mechanisms to prevent theft or unauthorized access.

Part 2: Types of Machinist Tool Boxes – Exploring Options for Every Need

Level 1: Common Categories of Machinist Tool Boxes

There are several types of machinist tool boxes available, each catering to different preferences, budgets, and applications. Below are some of the most popular categories:

- Rolling Tool Cabinets:

Rolling tool cabinets are large, mobile units equipped with drawers and shelves, designed for use in fixed workshop environments. They provide ample storage space and often feature heavy-duty casters for easy mobility around the shop floor. These cabinets are perfect for machinists who need quick access to a wide variety of tools and supplies. - Portable Tool Chests:

Portable tool chests strike a balance between capacity and convenience. Typically featuring multiple stacked drawers, these chests are compact enough to transport yet spacious enough to hold a comprehensive set of tools. Their portability makes them ideal for fieldwork or smaller workshops where space is limited.

Level 2: Specialty Tool Boxes for Unique Applications

Beyond mainstream options, specialty machinist tool boxes address niche requirements or specialized scenarios.

- Compact Tool Bags:

Tool bags are soft-sided carriers designed for light-duty tasks or travel. Made from durable canvas or ballistic nylon, they often include padded compartments and external pockets for organizing hand tools and accessories. These bags are favored by freelance machinists and technicians who require flexibility and ease of transport. - Modular Systems:

Modular tool box systems allow users to customize their setup according to changing needs. Individual components—such as drawer inserts, wall panels, and pegboards—can be rearranged or expanded over time. This adaptability makes modular systems particularly appealing for growing businesses or evolving projects.

Part 3: How Machinist Tool Boxes Enhance Productivity – Beyond Organization

Level 1: Encouraging Efficiency and Precision

Machinist tool boxes play a vital role in streamlining workflows and ensuring precision during machining operations.

- Minimizing Downtime During Tasks:

An organized tool box reduces the time spent locating specific tools, allowing machinists to focus on their work without interruptions. This increased efficiency translates into faster project completion times and higher output quality. - Protecting Tools and Equipment:

High-quality tool boxes shield delicate instruments from dust, moisture, and impacts, preserving their accuracy and functionality. For example, cushioned compartments protect fragile items like micrometers and dial indicators, while secure latches prevent accidental spills or falls.

Level 2: Supporting Professionalism and Confidence

Beyond practical benefits, machinist tool boxes contribute to fostering professionalism and self-assurance among users.

- Empowering DIY Enthusiasts and Professionals Alike:

Whether you’re a seasoned machinist or a beginner learning the craft, a well-equipped tool box instills confidence in your abilities. Knowing that all your tools are organized and within reach allows you to tackle complex projects with greater assurance. - Enhancing Workshop Aesthetics and Functionality:

A sleek, well-maintained tool box adds a touch of professionalism to any workspace. It creates a clean, organized environment that inspires creativity and discipline, encouraging users to take pride in their work.

Part 4: Practical Considerations – Choosing and Maintaining Your Machinist Tool Box

Level 1: Tips for Selecting the Right Tool Box

With so many variations available, choosing the perfect machinist tool box requires careful consideration of several factors.

- Capacity and Size Requirements:

Before purchasing a tool box, assess the number and size of tools you plan to store. Larger collections may necessitate rolling cabinets or multi-drawer chests, while smaller setups can suffice with portable cases or bags. - Mobility and Portability Needs:

Consider how frequently you’ll need to move your tool box. If portability is a priority, opt for lightweight designs with ergonomic handles or built-in wheels. Conversely, stationary setups benefit from heavier, more stable constructions.

Level 2: Maintenance and Longevity

Proper care ensures your machinist tool box remains functional and attractive over time.

- Regular Cleaning and Inspection:

Dust and debris can accumulate inside tool boxes, potentially damaging sensitive instruments. Regularly clean interior surfaces with a damp cloth and mild detergent, and inspect moving parts like drawers and hinges for signs of wear. - Preventing Rust and Corrosion:

For metal tool boxes, apply a thin layer of protective oil or wax to exposed surfaces to guard against rust. Store the box in a dry area whenever possible, and consider using silica gel packets to absorb excess moisture.

Part 5: Behind the Scenes – The Making of Machinist Tool Boxes

Level 1: The Development Process

Creating machinist tool boxes involves meticulous planning and execution to ensure safety, performance, and aesthetic appeal.

- Concept Development:

Designers collaborate with engineers, machinists, and end-users to develop concepts that balance visual design with functional performance. Inspiration comes from observing common challenges faced in workshops and identifying market gaps. - Testing and Refinement:

Once a prototype is developed, rigorous testing ensures consistency in strength, ergonomics, and ease of use. Feedback loops refine the product until it meets the brand’s exacting standards.

Level 2: Manufacturing Techniques

Advanced manufacturing techniques enable brands to produce high-quality machinist tool boxes at scale while maintaining precision and consistency.

- Material Selection and Treatment:

Premium materials like stainless steel, aluminum alloys, and reinforced polymers undergo stringent quality checks. Special treatments protect against corrosion, fatigue, or breakage, ensuring longevity. - Quality Assurance:

Final inspections include stress tests, finish evaluations, and dimensional checks to guarantee compliance with industry standards. Only products that pass all quality checks are approved for distribution, ensuring customer satisfaction.

Accessories That Enhance Your Machinist Tool Box Experience

Level 1: Essential Accessories for Everyday Use

Certain accessories can significantly improve the functionality and enjoyment of your machinist tool box.

- Drawer Liners and Foam Inserts:

Use non-slip drawer liners or custom-cut foam inserts to keep tools securely in place and prevent scratches or rattling. Always check compatibility before purchasing additional components. - Locking Mechanisms and Security Features:

Upgrade your tool box with advanced locking systems, such as combination locks or biometric scanners, to protect valuable tools from theft or tampering.

Level 2: Creative Enhancements

Take your machinist tool box experience to the next level with these creative additions.

- LED Lighting Kits:

Install LED strips or spotlights inside your tool box for better visibility, especially when working in low-light conditions. This customization fosters ownership and pride among users. - Interactive Storytelling Tools:

Augmented reality apps or QR codes linked to multimedia content can enrich the tool box’s narrative, providing insights into its creation, history, and cultural significance.

By understanding what makes machinist tool boxes exceptional, exploring diverse designs, leveraging expert tips, and embracing future innovations, you can fully unlock their potential. Whether you’re seeking affordability, craftsmanship, or symbolism, these tool boxes offer endless possibilities—one step closer to achieving precision and excellence!

Conclusion: Embracing the Versatility of Machinist Tool Boxes

Level 1: Celebrating Innovation and Reliability

Machinist tool boxes embody the perfect blend of functionality and craftsmanship, offering endless possibilities for enhancing productivity and organization. Their ability to adapt to changing needs underscores their universal appeal.

- A Universal Solution:

Whether you’re a professional machinist, a hobbyist, or a technician, machinist tool boxes cater to diverse skill levels and requirements. Their versatility ensures they remain relevant across industries and generations. - Inspiring Future Innovations:

As technology advances and consumer demands evolve, machinist tool boxes will continue to inspire creativity. Smart integrations, sustainable practices, and inclusive designs promise exciting developments in the years to come.

Level 2: Looking Ahead – Trends Shaping the Industry

With ongoing advancements in sustainability, inclusivity, and technology, the future of machinist tool boxes holds immense potential for growth and reinvention.

- Eco-Friendly Initiatives:

Manufacturers are increasingly prioritizing eco-conscious practices, such as using recyclable materials, reducing packaging waste, and designing products with extended lifespans. These efforts resonate with environmentally aware consumers seeking guilt-free purchases. - Tech-Enhanced Features:

Imagine smart tool boxes equipped with RFID tags to track inventory, digital locks for enhanced security, or integrated charging stations for power tools. Such innovations would redefine how users interact with their equipment, blending functionality with cutting-edge technology.

The Wiper Arm Removal Tool: Simplifying Maintenance Tasks

Part 1: Introduction to Wiper Arm Removal Tools – Why They Matter

Level 1: What Is a Wiper Arm Removal Tool?

A wiper arm removal tool is a specialized automotive device designed to safely and efficiently remove windshield wiper arms from their mounting points. These tools are essential for car owners, mechanics, and DIY enthusiasts who need to replace or repair wiper arms without causing damage to the vehicle’s windshield or wiper system. By providing leverage and precision, wiper arm removal tools ensure that the process is both quick and hassle-free.

- The Importance of Proper Wiper Arm Maintenance:

Windshield wipers play a critical role in ensuring visibility during inclement weather. Over time, however, wiper arms can become worn, misaligned, or damaged, compromising their effectiveness. Replacing these components requires careful handling to avoid scratching the windshield or damaging the wiper motor assembly. A wiper arm removal tool simplifies this task by offering a controlled method for detachment. - Why Use a Dedicated Tool?

Attempting to remove wiper arms with makeshift tools or brute force can lead to costly repairs. For instance, prying off an arm improperly might crack the windshield or strip the wiper arm threads. A dedicated removal tool minimizes these risks, making it an indispensable addition to any toolkit.

Level 2: Key Features of Wiper Arm Removal Tools

Understanding what sets wiper arm removal tools apart highlights their value in automotive maintenance.

- Design Variations and Compatibility:

Wiper arm removal tools come in various designs, including puller-style, fork-style, and universal adapters. Each type caters to specific vehicle models and wiper arm configurations. Some tools feature adjustable jaws or interchangeable heads to accommodate different sizes and shapes. - Durability and Ease of Use:

High-quality wiper arm removal tools are typically made from durable materials like hardened steel or reinforced plastic. Ergonomic handles and non-slip grips enhance user comfort, while corrosion-resistant coatings ensure longevity even under harsh conditions.

Part 2: Types of Wiper Arm Removal Tools – Exploring Options for Every Need

Level 1: Common Categories of Wiper Arm Removal Tools

There are several types of wiper arm removal tools available on the market, each tailored to specific applications and preferences. Below are some of the most popular categories:

- Puller-Style Tools:

Puller-style tools use a screw mechanism to apply even pressure and gently lift the wiper arm away from its mounting post. This design is particularly effective for vehicles with tight-fitting wiper arms, as it reduces the risk of slippage or damage. - Fork-Style Tools:

Fork-style tools consist of a U-shaped metal piece that slides under the base of the wiper arm. Once positioned, the tool acts as a lever to pry the arm loose. These tools are simple, affordable, and widely compatible with many vehicle makes and models.

Level 2: Specialty Tools for Unique Challenges

Beyond mainstream options, specialty wiper arm removal tools address niche requirements or complex scenarios.

- Universal Adapters:

Some tools include universal adapters or modular components that allow them to work across multiple vehicle brands and wiper arm designs. These versatile solutions are ideal for professional mechanics or individuals maintaining multiple vehicles. - Pneumatic-Assisted Tools:

For heavy-duty applications, pneumatic-assisted wiper arm removal tools provide additional power and precision. These tools are commonly used in commercial garages where efficiency and reliability are paramount.

Part 3: How Wiper Arm Removal Tools Enhance Your Maintenance Routine – Beyond Convenience

Level 1: Encouraging Safety and Efficiency

Wiper arm removal tools play a vital role in streamlining automotive maintenance tasks while prioritizing safety and accuracy.

- Preventing Damage During Removal:

Using a proper tool ensures that the delicate surfaces of your windshield and wiper system remain unharmed. This not only saves money on potential repairs but also extends the lifespan of your vehicle’s components. - Simplifying Complex Repairs:

Replacing wiper arms often involves navigating cramped spaces or dealing with rusted parts. A dedicated removal tool provides the leverage needed to overcome resistance without straining yourself or damaging surrounding areas.

Level 2: Supporting Professionalism and Confidence

Beyond practical benefits, wiper arm removal tools contribute to fostering confidence and professionalism among users.

- Empowering DIY Enthusiasts:

With the right tool, even novice car owners can tackle wiper arm replacements independently. This sense of accomplishment encourages further exploration into automotive maintenance and fosters self-reliance. - Enhancing Workshop Productivity:

For professional mechanics, having reliable wiper arm removal tools improves workflow efficiency. Tasks that once required significant effort and time can now be completed swiftly, allowing technicians to focus on more complex repairs.

Part 4: Practical Considerations – Choosing and Using Wiper Arm Removal Tools

Level 1: Tips for Selecting the Right Tool

With so many variations available, choosing the perfect wiper arm removal tool requires thoughtful consideration of several factors.

- Vehicle Compatibility:

Before purchasing a tool, verify its compatibility with your vehicle’s make and model. Consult your owner’s manual or online resources to determine the type of wiper arm attachment used in your car. - Material Quality and Build:

Opt for tools made from high-grade materials that resist wear and tear. Look for features like heat-treated steel, anti-corrosion coatings, and ergonomic designs that enhance usability and durability.

Level 2: Techniques for Safe and Effective Use

Mastering the correct usage of a wiper arm removal tool ensures optimal results and prevents accidents.

- Proper Positioning and Alignment:

Always position the tool securely before applying force. Misalignment can cause uneven pressure, leading to damage or incomplete removal. Double-check that all components are firmly seated before proceeding. - Avoiding Common Mistakes:

Over-tightening screws or applying excessive force can result in stripped threads or bent wiper arms. Work slowly and steadily, using only the amount of pressure necessary to disengage the part.

Part 5: Behind the Scenes – The Making of Wiper Arm Removal Tools

Level 1: The Development Process

Creating wiper arm removal tools involves meticulous planning and execution to ensure safety, performance, and aesthetic appeal.

- Concept Development:

Engineers collaborate with designers, mechanics, and end-users to develop concepts that balance visual design with functional performance. Inspiration comes from observing common challenges faced during wiper arm removal and identifying market gaps. - Testing and Refinement:

Once a prototype is developed, rigorous testing ensures consistency in strength, ergonomics, and ease of use. Feedback loops refine the product until it meets the brand’s exacting standards.

Level 2: Manufacturing Techniques

Advanced manufacturing techniques enable brands to produce high-quality wiper arm removal tools at scale while maintaining precision and consistency.

- Material Selection and Treatment:

Premium materials like stainless steel, aluminum alloys, and reinforced polymers undergo stringent quality checks. Special treatments protect against corrosion, fatigue, or breakage, ensuring longevity. - Quality Assurance:

Final inspections include stress tests, finish evaluations, and dimensional checks to guarantee compliance with industry standards. Only products that pass all quality checks are approved for distribution, ensuring customer satisfaction.

Accessories That Enhance Your Wiper Arm Removal Experience

Level 1: Essential Accessories for Everyday Use

Certain accessories can significantly improve the functionality and enjoyment of your wiper arm removal tool.

- Protective Covers and Guards:

Use protective covers or guards to shield your windshield and surrounding areas during removal. Always check compatibility before purchasing additional components. - Lubricants and Cleaning Solutions:

Rust inhibitors or penetrating oils help loosen stuck bolts or corroded parts. These solutions ensure smooth operation and prevent future sticking.

Level 2: Creative Enhancements

Take your wiper arm removal experience to the next level with these creative additions.

- Customizable Handles and Grips:

Add custom handles, grips, or tassels to personalize your tool further. This customization fosters ownership and pride among users. - Interactive Storytelling Tools:

Augmented reality apps or QR codes linked to multimedia content can enrich the tool’s narrative, providing insights into its creation, history, and cultural significance.

By understanding what makes wiper arm removal tools exceptional, exploring diverse designs, leveraging expert tips, and embracing future innovations, you can fully unlock their potential. Whether you’re seeking affordability, craftsmanship, or symbolism, these tools offer endless possibilities—one step closer to hassle-free maintenance!

Conclusion: Embracing the Versatility of Wiper Arm Removal Tools

Level 1: Celebrating Innovation and Reliability

Wiper arm removal tools embody the perfect blend of functionality and ingenuity, offering endless possibilities for efficient and safe automotive maintenance. Their ability to adapt to changing needs underscores their universal appeal.

- A Universal Solution:

Whether you’re a seasoned mechanic or a first-time car owner, wiper arm removal tools cater to diverse skill levels and requirements. Their versatility ensures they remain relevant across generations and industries. - Inspiring Future Innovations:

As technology advances and consumer demands evolve, wiper arm removal tools will continue to inspire creativity. Smart integrations, sustainable practices, and inclusive designs promise exciting developments in the years to come.

Level 2: Looking Ahead – Trends Shaping the Industry

With ongoing advancements in sustainability, inclusivity, and technology, the future of wiper arm removal tools holds immense potential for growth and reinvention.

- Eco-Friendly Initiatives:

Manufacturers are increasingly prioritizing eco-conscious practices, such as using recyclable materials, reducing packaging waste, and promoting longevity through durable designs. These efforts resonate with environmentally aware consumers seeking guilt-free purchases. - Tech-Enhanced Features:

Imagine smart wiper arm removal tools equipped with sensors that detect alignment issues or provide real-time feedback during operation. Such innovations would redefine how users interact with their tools, blending functionality with cutting-edge technology.