Advantages and application scenarios of T track stopper

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. Compared with traditional positioning devices, T-slot miter rail jig has many advantages and can be applied in various scenarios. This article will introduce the advantages and application scenarios of the stopper in detail, hoping to help you better understand and use stopper.

Advantages of T track stopper

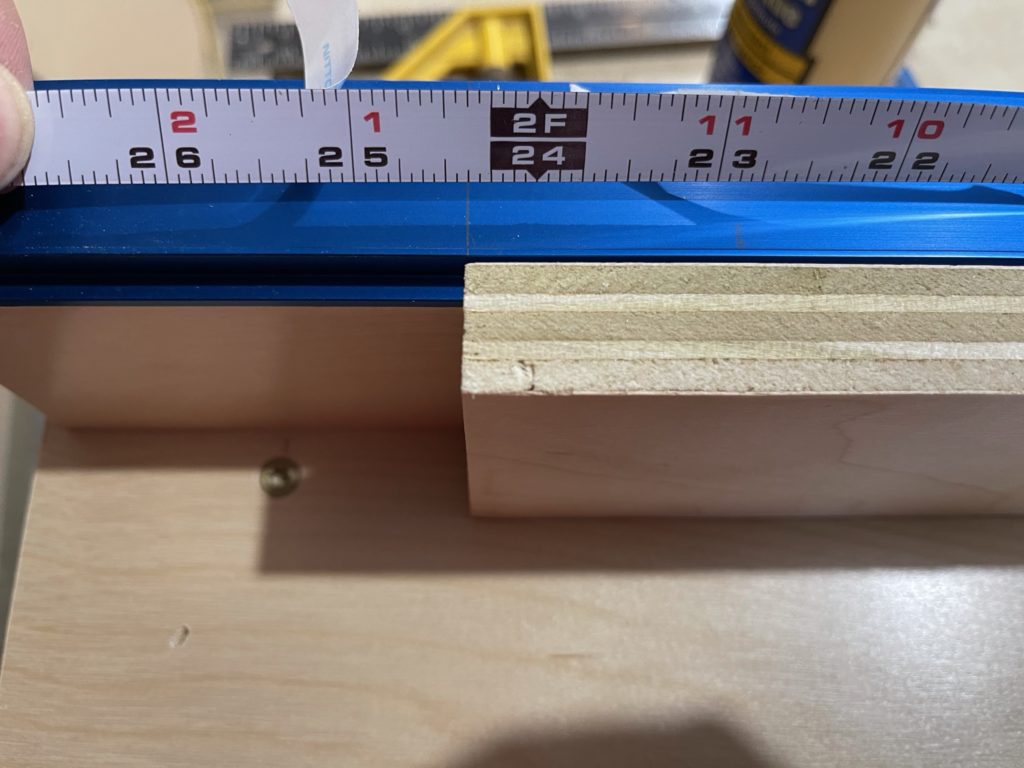

- Precise positioning: the stopper can achieve precise positioning by fixing and positioning the workpiece, avoiding the overall effect being affected by errors.

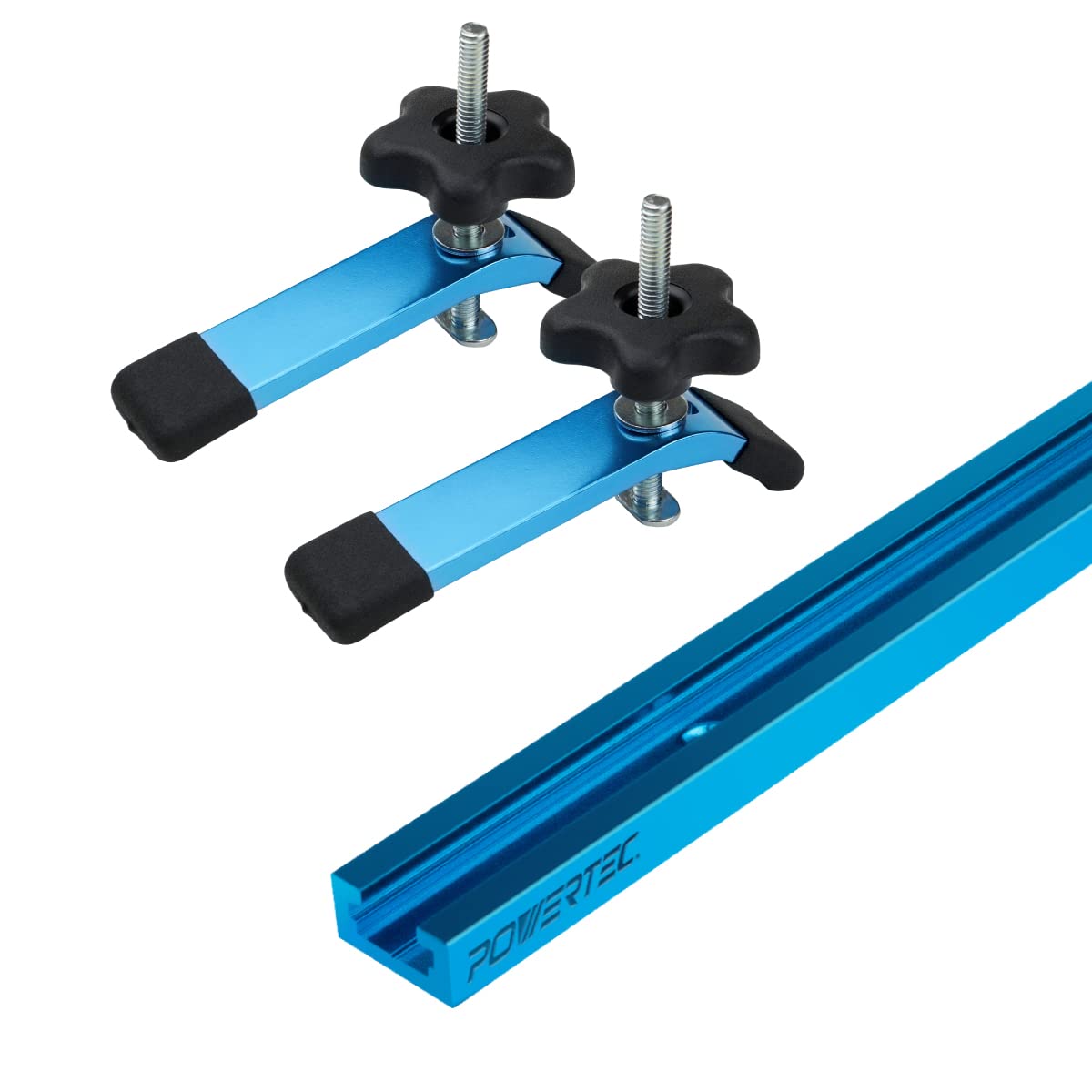

- High stability: T track stopper adopts control mechanisms such as fixed blocks, adjustment rods, handles, knobs, sliding blocks, etc., which can realize stable fixing of workpieces and avoid workpieces from moving or shaking.

- Easy to operate: T-slot miter rail jig is easy to operate. It needs to adjust the position and fixing degree of the workpiece through control mechanisms such as handles, knobs, and sliders. It is suitable for different operating requirements and processing scenarios.

- Wide range of applications: the stopper can be applied to various scenarios such as making furniture, making models, and doing DIY projects, and is suitable for different workpieces and processing needs.

- Cost saving: stopper can improve machining accuracy and efficiency by fixing and positioning workpieces, reduce machining costs and improve production efficiency.

Application scenarios of T track stopper

- Making furniture: When making furniture, the stopper and T-shaped track can be used to fix and position the workpiece, improving processing accuracy and efficiency. For example, when making cabinet doors, drawers and other furniture parts, you can use T track stopper to achieve precise positioning and fixing.

- Model making: When making models, T-slot miter rail jigs and T-shaped tracks can be used to precisely position the workpiece to avoid affecting the overall effect due to errors. For example, to make aircraft models, car models, etc., you can use stopper to achieve precise positioning and fixing of workpieces.

- Do DIY projects: When doing DIY projects, the stopper and the can be used to help DIY enthusiasts complete various processing projects more easily. For example, to make simple furniture, DIY lamps, etc., you can use T-slot miter rail jig to quickly locate and fix the workpiece.

- Machining: In machining, stopper can be applied to various processing scenarios, such as drilling, cutting, etc. By accurately positioning and fixing the workpiece, the machining accuracy and efficiency can be improved.

- Woodworking processing: In woodworking processing, the stopper can be applied to making furniture, making wooden tools and other scenes. By accurately positioning and fixing the workpiece, the machining accuracy and efficiency can be improved.

How to install T track stopper?

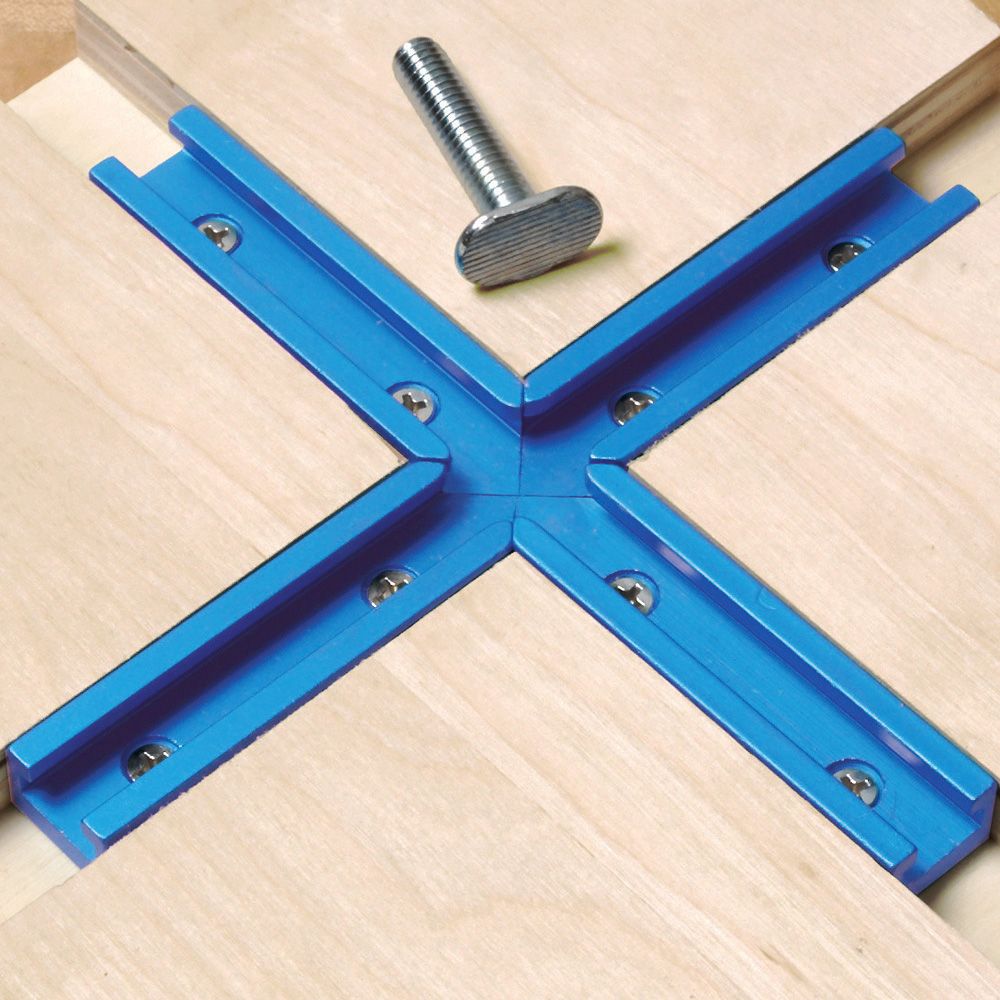

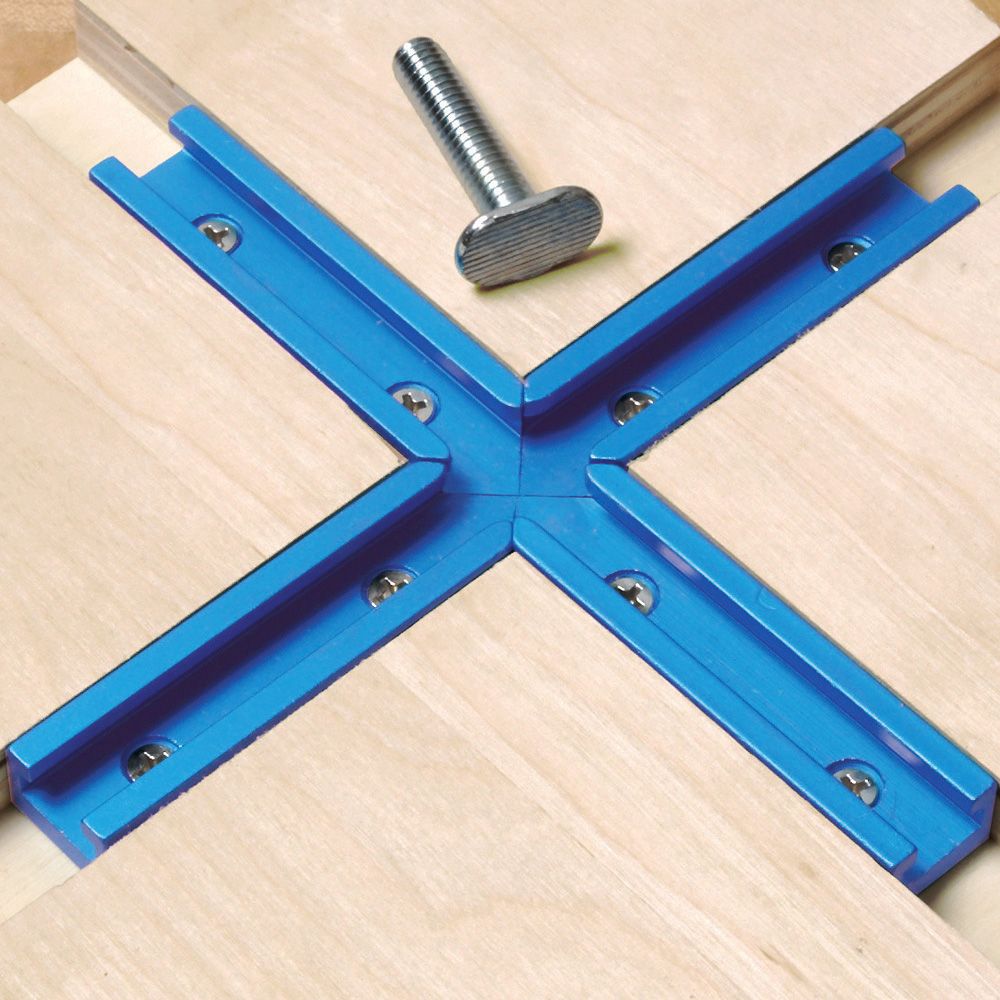

Fix the Stopper: After the Stopper is inserted into the T-shaped track, fix the T-slot miter rail jig in the T-shaped track with screws or other fixing parts. When fixing the T Track Stopper, you need to pay attention to the following points:

- Make sure the length and diameter of the fixing part matches the T-track, not too long or too short.

- When fixing the Stopper, it is necessary to ensure that the position of the T-slot miter rail jig is correct and stable to prevent it from loosening or moving during use.

In short, the stopper has the advantages of precise positioning, high stability, easy operation, wide application range, cost saving, etc., and can be applied in various scenarios. When using the stopper, you need to pay attention to safety and maintenance, so as to better realize the processing and production of workpieces.