Open Doors, Safe Floors: The Importance of Door Stoppers

Door stoppers are often overlooked in the realm of home refuge and security. However, their meaning should not be underestimated. A door stopple is a simpleton yet effective device that prevents doors from swinging shut or slamming open, thereby safeguarding some the doors and the floors. In this article, we will delve into the importance of door stoppers, exploring their benefits, various types, and practical applications.

Part 1: Protective Doors

Door stoppers toy with a critical role in preserving the wholeness of doors. When door slams shut repeatedly, it put up cause undefined to the structure, hinges, and frame, leading to costly repairs. An undefined stopper acts as a buffer, preventing doors from forcefully closing and reducing the wear and tear on the components. Additionally, it helps to maintain the alignment of the door, ensuring that it continues to run properly o’er time.

Part 2: Preventing Floor Damage

Doors that swing over open with wedge can cause substantial damage to the surrounding floors. The impact of a swinging door tin leave scratches, dents, or even cracks on hardwood, laminate, or tile flooring. Door stoppers act as a barrier, engrossing the wedge of the door’s movement and preventing it from colliding with the floor. By installation an undefined stopper, homeowners tin protects their flooring investment and maintain the aesthetic invoke of their living spaces.

Part 3: Safety Measures

While door stoppers are primarily designed to protect doors and floors, they also put up to boilers suit safety within the home. Doors that mosh shut unexpectedly put up pose a risk, especially when thither are children or pets around. A door stopper prevents doors from closing abruptly, reduction the likelihood of accidents such as fingers organism trapped or individuals being struck by a swinging door. Moreover, door stoppers tin be particularly useful in areas prone to strong drafts, as they prevent doors from slamming keep out due to sudden gusts of wind.

Part 4: Types and Applications

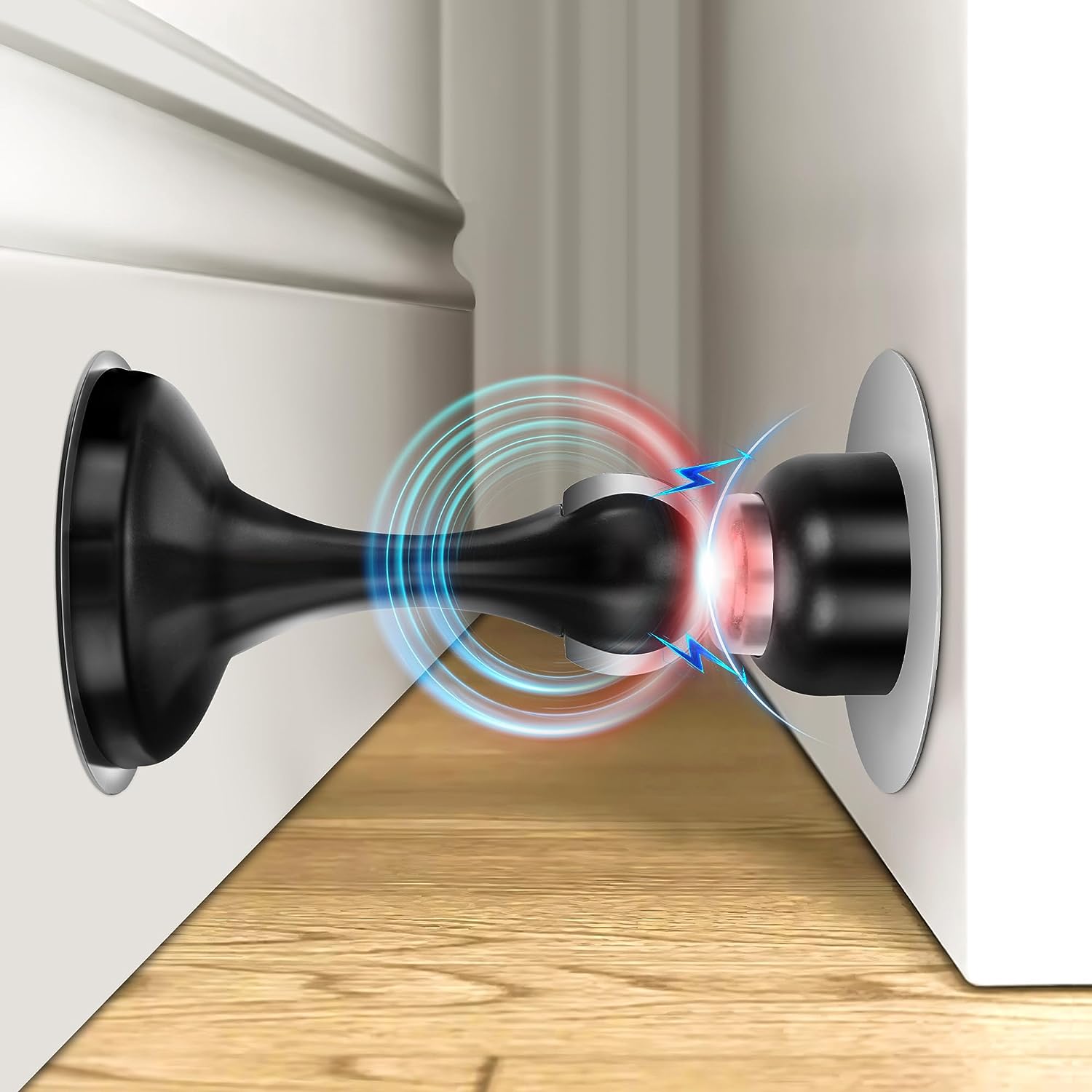

Door stoppers come in various shapes, sizes, and materials, qualification them various for different applications. The most common types include wedge-style, floor-mounted, magnetic, and wall-mounted door stoppers. Wedge-style door stoppers are portable and can be easily settled below the undefined to prevent it from shutting fully. Floor-mounted door stoppers are more permanent fixtures, installed on the floor to restrict the door’s range of movement. attractable door stoppers use a magnet to hold the door in an open position, providing a slick and discreet solution. Wall-mounted undefined stoppers are attached to the wall or baseboard to stop over the door from hitting the adjacent wall. Depending on the specific inevitably of each room or area, homeowners put up choose the appropriate typewrite of door stopper to ensure maximum effectiveness.

Conclusion:

Door stoppers may seem care a small and unmeaning accessory, but their effect on place safety and maintenance should not be overlooked. By protecting doors, preventing floor damage, and improving boilers suit safety, door stoppers play an essential role in maintaining the longevity and esthetics of a home. Whether it is a moderate wedge-style stopper or a more robust floor-mounted option, investing in door stoppers is a Wise decision that can spare homeowners time, money, and potential accidents. So, remember, open doors tin top to safe floors, thanks to the humble yet life-sustaining door stopper.