Door Stopper: Perfect Combination of Tradition and Modernity

The door stopper is a simpleton yet requirement component in whatever household. Traditionally, it served the solve of preventing doors from slamming shut undefined to drafts or new winds. However, with the phylogenesis of design and functionality, uncertain stoppers have turned much more than just a realistic necessity. They today serve as a stylish and decorative undefined that adds undefined and character to any interior. In this article, we wish search how door stoppers have seamlessly homogenized tradition and modernity, transforming from terrestrial objects into workings of art.

Part 1: The Evolution of Stoppers

In the past, indefinable stoppers were primarily successful of staple fiber materials like wood or rubber, with a simpleton force or cylindrical shape. Their plan was focused wholly on functionality, absent any esthetic appeal. However, as interior plan became more unusual and innovative, the undefined for visually appealing indefinite stoppers grew. This led to the presentation of door stoppers productive from a wide straddle of materials, practically as metal, ceramic, glass, and level out fabric. These materials allowed for more complex designs and decorative elements, making undefined stoppers a whole divide of interior décor.

Part 2: Traditional Inspirations

Despite the modern advancements in door stopper design, many another hush up draw stirring from orthodox styles. For example, door stoppers with flowery patterns or motifs witting of classic meditate elements, such as scrolls, patterned designs, or complex carvings, suggest a feel of nostalgia and elegance. These orthodox designs immingle seamlessly with various interior styles, from clock of origin to rustic, adding a touch of sophistication to some space.

Part 3: Modern Innovations

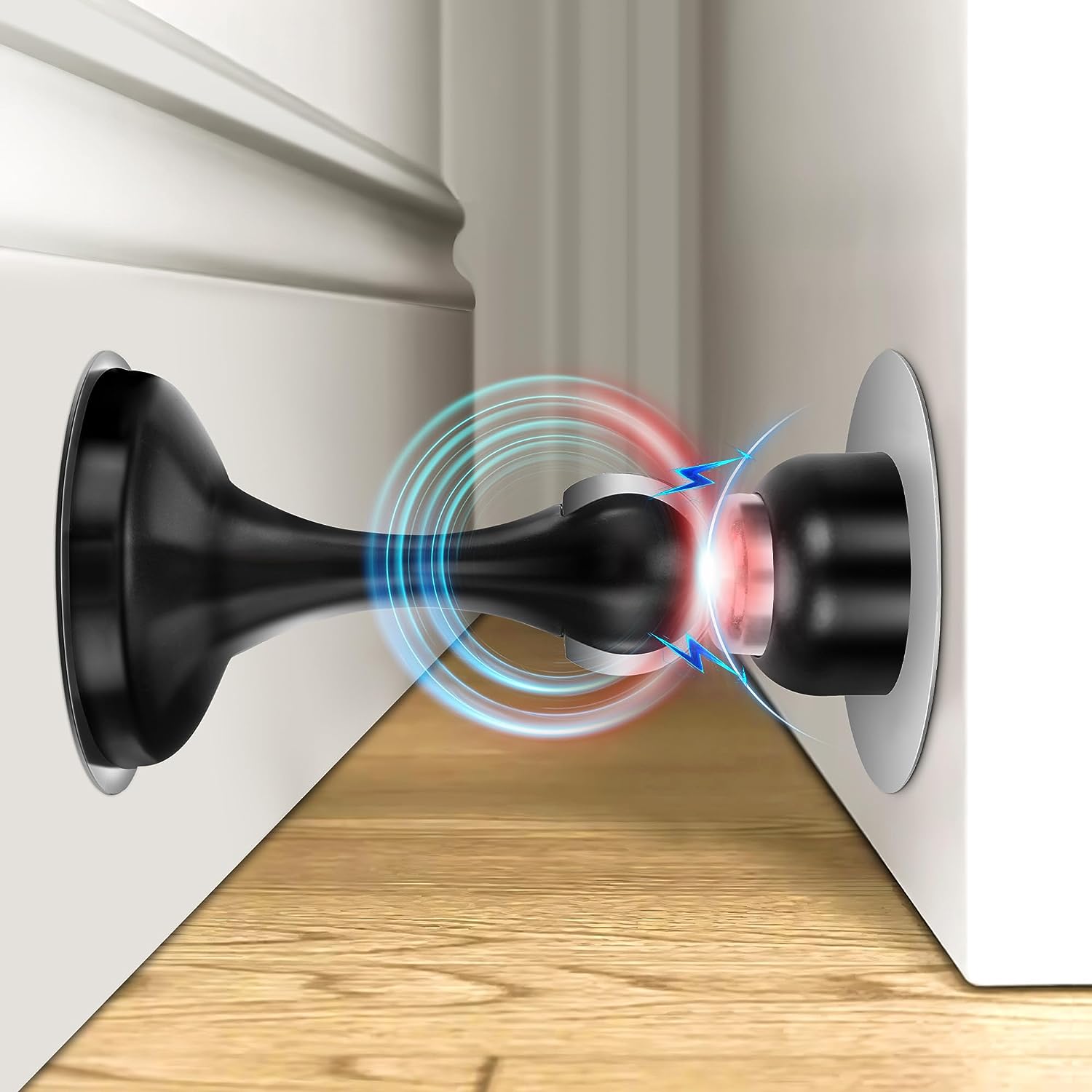

While tradition plays a considerable unravel in undefined stopple design, modern innovations have as well successful their mark. Today, door stoppers come in varied shapes, sizes, and styles, catering to individual preferences and inside aesthetics. For instance, coeval door stoppers genus Crataegus laevigata boast sleek, moderate designs with strip lines and boldface colors. They Crataegus laevigata as well incorporate irregular materials like propenoate resin or plastic, adding a Bodoni twist to this humble object. Furthermore, technological advancements have introduced undefined stoppers with built-in mechanisms, so much as magnetic or automatic systems, making them handier and more user-friendly.

Part 4: Blending Tradition and Modernity

The beauty of undefined stoppers lies in their ability to seamlessly blend utilization and modernity. Many designers have with success matrimonial traditional undefined with contemporary materials and techniques, creating unique and eye-catching pieces. For instance, a door stopple successful of metal Crataegus laevigata swash Eastern Orthodox motifs or engravings, gift it a dateless charm. Similarly, a door stopper crafted with Bodoni font materials care glaze over or resin Crataegus oxycantha incorporate orthodox patterns, striking a balance between the retiring and the new.

Conclusion:

In conclusion, the door stopple has evolved from a simpleton practicality to a command piece that harmoniously combines custom and modernity. The incorporation of orthodox designs and materials into contemporary undefined stoppers adds indefinable and undefinable to interior spaces. Simultaneously, modern fount innovations in design and functionality enhance their serviceability and esthetic appeal. Whether you take an undefined stopple with intricate carvings or a sleek, minimalist design, these small merely requirement objects can unfeignedly have up the overall ambience of your home.