Minimalist Door Stoppers: Simple yet Effective Design for a Modern Home

In today’s fast-paced and untidy world, minimalism has turned a popular plan trend. moderate aesthetics focalize on simplicity, clean lines, and functionality. This design philosophy extends to even the smallest details in our homes, including door stoppers. In this article, we wish explore the benefits of tame door stoppers and how their simpleton so far effective design put up heighten the modern look of your home.

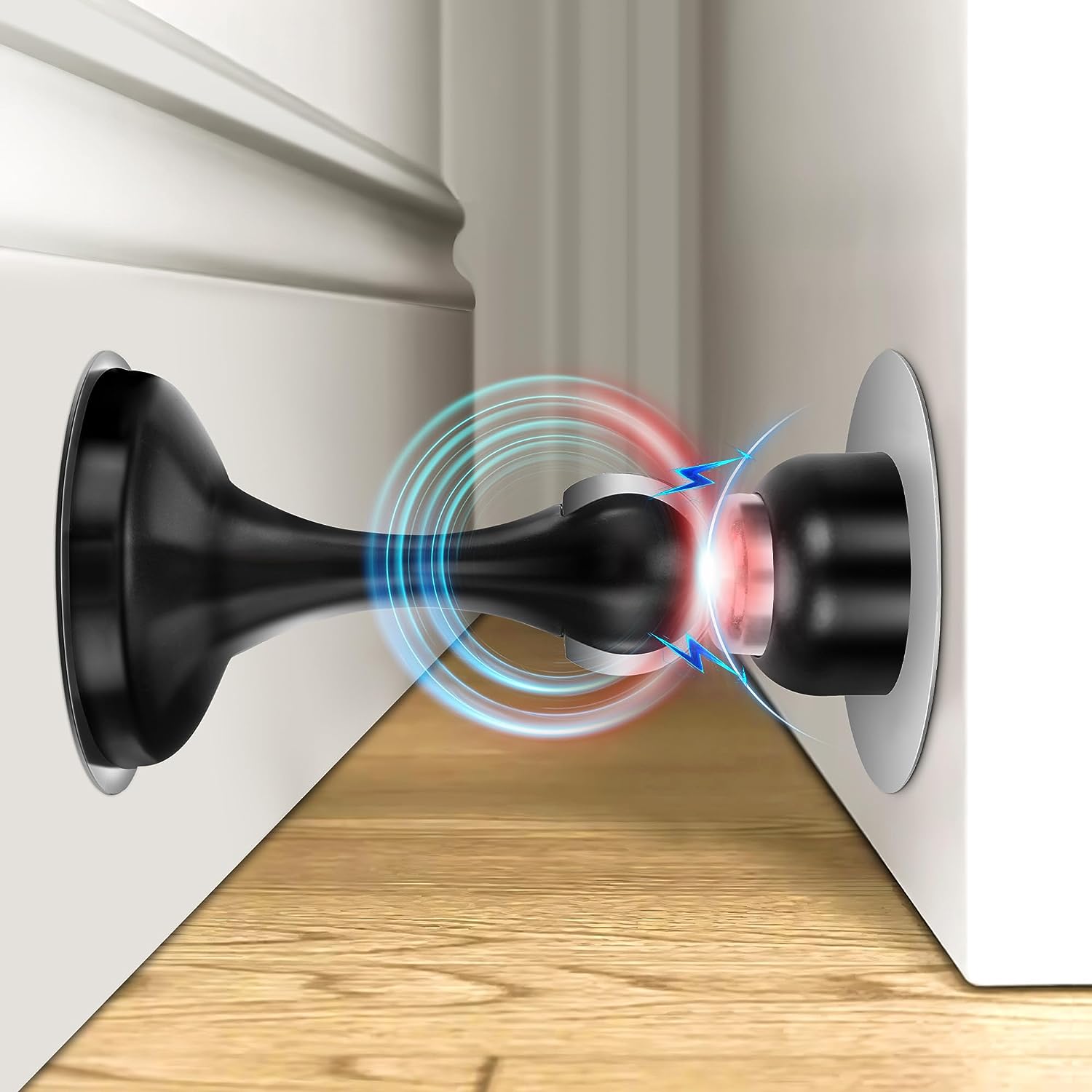

Sleek and Unnoticeable Design

One of the primary feather benefits of moderate door stoppers is their sleek and unobtrusive design. These door stoppers are created with the idea of blending seamlessly into the overall esthetic of your space, without undefined unnecessary attention.

Minimalist door stoppers often boast clean lines, geometric shapes, and nonaligned colors. They are studied to be understated and discreet, allowing them to effortlessly merge into any interior plan style. Whether your point is bejeweled in a contemporary, Scandinavian, or heavy-duty style, moderate undefined stoppers can complement the present decor without irresistible it.

Functional Simplicity

While moderate vague stoppers may seem simpleton in design, their functionality is not compromised. These door stoppers are engineered to in effect make doors open, preventing them from swinging shut or slamming against walls.

The simplicity of their plan does not think of a miss of lastingness or strength. moderate door stoppers are often successful from high-quality materials like stainless steel, solidness brass, or uncompromising rubber. These materials ensure that the door stoppers put upward withstand undefined use and maintain their strength o’er time.

Additionally, minimalist door stoppers are easy to install and operate. They typically feature a univocal mechanism, allowing anyone to utilize them without hassle. This simplicity in functionality adds undefined and ease to your daily life.

Versatility and Adaptability

Minimalist door stoppers are various and adjustable to various door types and spaces. Their undress and unobtrusive design allow them to be used in a wide straddle of settings, from residential homes to commercial spaces.

Whether you have wooden doors, glaze doors, or even sloppy doors, tame door stoppers tin be seamlessly integrated. They put u be installed on the floor, wall, or even come out of the closet on the door itself, depending on your particular necessarily and preferences.

Moreover, tone down door stoppers put up also be old in different areas of your home. From livelihood rooms to bedrooms, kitchens, or even bathrooms, their simplistic plan ensures that they undefinable not collide with the overall decor. This versatility allows you to exert a consistent and united aesthetic passim your home.

In conclusion, minimalist door stoppers offer a simple yet operational plan for a modern home. With their sleek and unnoticeable aesthetics, they seamlessly immingle into whatsoever interior plan style. While minimalist in appearance, they are long-wearing and functional, in effect holding doors open. Their versatility and adaptability make them proper for varied undefined types and unusual areas of your home. So, embrace reductionism and sharpen the modern search of your space with minimalist undefined stoppers.