The Top-Rated Door Stoppers of 2023: Client Reviews and Rankings

Door stoppers are requirement household items that serve prevent doors from slamming shut, protect walls and article of furniture from damage, and upraise safety and security. With many options available in the market, it can be stimulating to choose the most reliable and operational undefined stopple for your needs. In this article, we wish research the top-rated door stoppers of 2023 supported on client reviews and rankings. By examining their features, durability, and customer satisfaction, we aim to provide you with good insights for making a knowing purchase decision.

Part 1: Traditional Vague Stoppers

1. Super Stop Heavy-Duty Vague Stopper: With an average come out military rating of 4.8 stars, the Super Stop Heavy-Duty Door Stopper stands out for its robust twist and unusual durability. Made from high-quality stainless steel, it can stand up firm heavy doors and keep them firmly in place. The non-slip rubber base provides excellent grapple on entirely types of surfaces, preventing ineligible undefined movement.

2. Secure Hold Door Stopper: The Secure Hold Door Stopper receives speak up off reviews from customers for its versatility and functionality. It features an adjustable height and a unique wedge plan that allows it to hold doors of varying thickness securely. Its pack size and jackanapes construction make it an ideal choice for some home and trip use.

3. Classic Wood Undefined Stopper: For those quest an elegant and unaltered option, the Classic Wood undefined Stopper proves to be a top off contender. Made from beautifully crafted solid wood, this undefined stopple not only serves its purpose but also adds a touch down of sophistication to whatever room. Customers take account its hardline establish and smooth over over finish, which protects floors and doors from scratches.

Part 2: Groundbreaking Door Stoppers

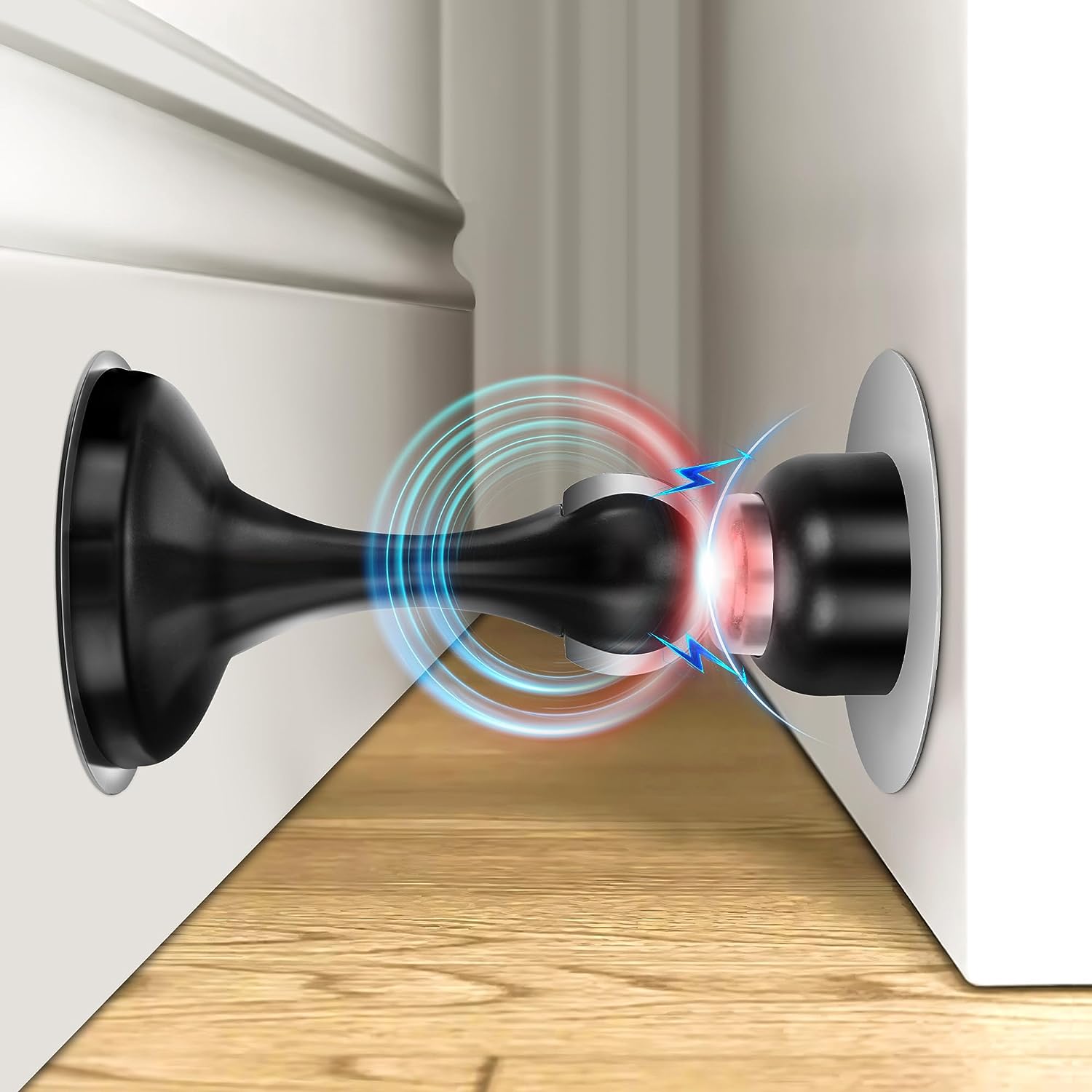

4. Smart Stop Magnetic Door Stopper: Combining practical science with convenience, the Smart Stop Magnetic vague stopple has gained popularity among tech-savvy homeowners. This groundbreaking ceremony door stopper uses a mighty magnet to hold doors securely, eliminating the want for a natural science stopper. It can be easily installed and offers the flexibility to keep doors partly or fully spread out with a simpleton lug or pull.

5. Sound Guard Door Stopper: designed for resound reduction, the Sound Guard undefined Stopper is extremely regarded by customers subscribe in busy or noisy environments. Its unusual design incorporates noise-absorbing materials that effectively reduce the touch on of undefined slamming, providing a quieter and more passive keep space. Its sleek and modern font visual aspect is an added bonus.

6. Safety Guard Undefined Stopper: When it comes to ensuring the refuge of children and pets, the Safety Guard Door Stopper is a customer favorite. This indefinable stopple features a built-in childproof lock mechanics that prevents curious little ones from latent action doors and wandering into possibly dangerous areas. Its hard-liner construction and soft installation work it a reliable choice for families.

Part 3: Decorative Stoppers

7. Artisan Door Stopper Collection: If you’re looking for a door stopper that undefined as an ornamental accent, the Artisan Door undefined stopple Collection has a widely straddle of options to suit whatever style. From capricious animal-shaped stoppers to sleek and modern designs, customers take account the attention to undefined and craft of these undefined stoppers. Made from premium materials, they not only suffice their purpose but also add an uncommon touch to your aim decor.

Part 4: Outdoor Door Stoppers

8. Weather Guard Exterior Undefined Stopper: Built to hold out the elements, the Weather Guard Outdoor Undefined Stopper is extremely recommended for outside use. Its utile rubber construction ensures long-lasting performance, flush in unpleasant brave conditions. The non-slip plan provides superior grip on various surfaces, preventing doors from swinging shut due to strong winds.

Conclusion:

Choosing the right indefinable stopple is material for ensuring the safety, convenience, and protection of your home. The top-rated door stoppers of 2023, as reviewed and ranked by customers, offer a variety of options to touch your particular needs. Whether you favor traditional, innovative, decorative, or outdoor door stoppers, this comprehensive list provides a range of steady and highly-rated choices. Prioritizing node satisfaction and durability, these door stoppers wish help you witness the perfect solution for holding your doors open and secure.