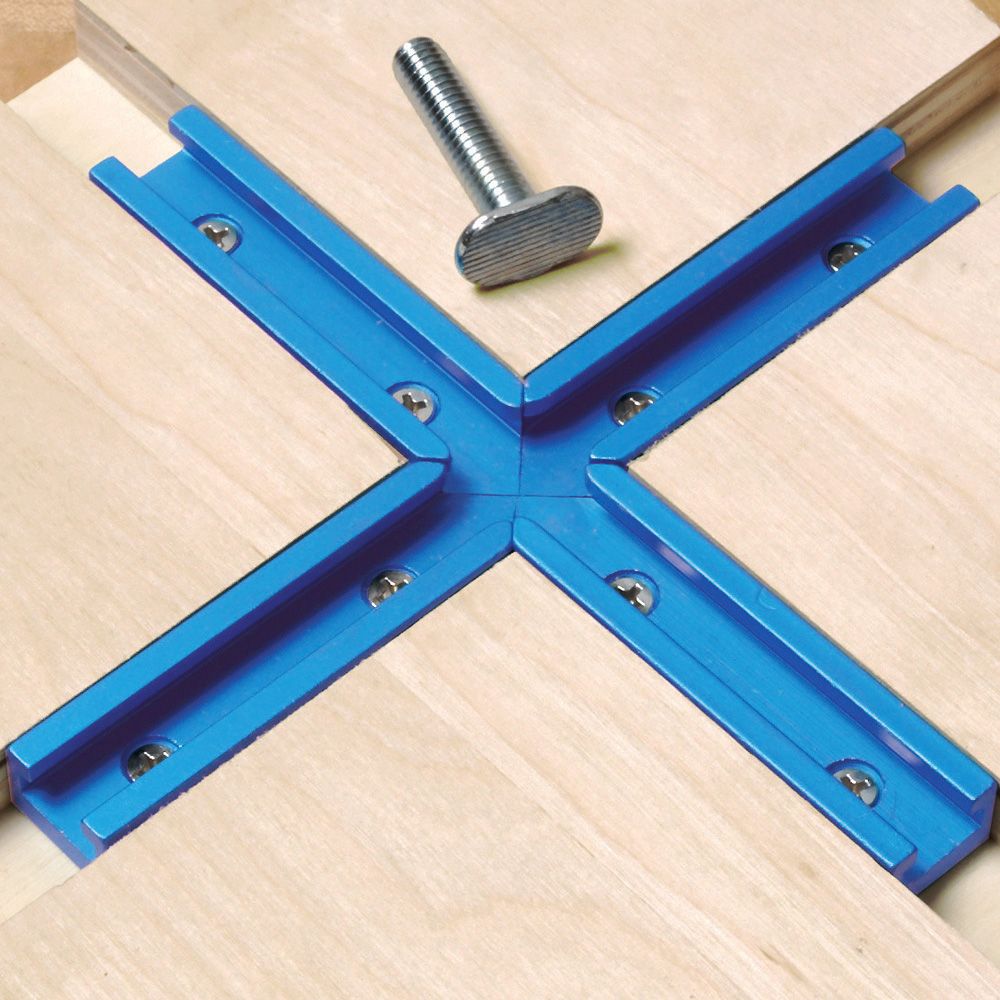

The stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. In the use of stopper, it is very important to cooperate with the T-slot miter rail jig. This article will introduce the use of T track stopper and the in detail, hoping to help you better understand and use the stopper.

Principle of T track stopper and T track

The stopper can be used in conjunction with the T-shaped track, and the workpiece can be fixed and positioned through the groove of the T-shaped track, thereby improving machining accuracy and efficiency.

T-rails are usually made of aluminum and have a T-shaped section that can be joined by slots to create tracks of different lengths. In the T track, the groove can be used to place the stopper, so as to fix and position the workpiece.

T-slot miter rail jig is usually made of metal or plastic, and the position and fixing degree of the workpiece can be fixed and adjusted through control mechanisms such as handles, knobs, and sliding blocks. When using the stopper, it needs to be placed in the groove in the T-shaped track, and the position and fixation degree of the workpiece can be fixed and adjusted through control mechanisms such as handles, knobs, and sliders, so as to achieve precise positioning and fixing of the workpiece.

Advantages and disadvantages of T track stopper and T track

The combination of T-slot miter rail jig and T track has the following advantages and disadvantages:

- Advantage:

- Precise positioning: the precise positioning and fixing of the workpiece can be achieved through the combined use of the stopper and the T-shaped track.

- Improve processing efficiency: Through the combined use of the stopper and T-shaped track, the processing efficiency can be improved and the workpiece can be prevented from sliding or tilting during processing.

- Simple and easy to use: the use of T-slot miter rail jig and is easy to understand and does not require complicated operation skills.

- Shortcoming:

- Need to be used together:Stopper and T-shaped track need to be used together, if there is a problem with one of them, it will affect the entire machining process.

- Not suitable for all workpieces: the stoppers and T-tracks are suitable for most workpieces, but for some special shaped workpieces, other positioning devices may be required.

- Higher cost: the cost of T-slot miter rail jig and T-shaped track is higher, which may be a certain pressure for some users with limited budget.

How to care and maintain the stopper and T track?

In order to ensure the normal use of the stopper and the T-shaped track, regular maintenance and maintenance are required:

- Cleaning: Regularly clean the and T-slot miter rail jig to avoid dust and impurities from affecting the working effect.

- Lubrication: Use oil or grease regularly to keep the stopper and the running smoothly.

- Adjustment: Regularly adjust the position and degree of fixation of the stopper to ensure machining accuracy and efficiency.

- Inspection: Regularly inspect the and T-slot miter rail jig for damage or malfunction.

Summarize

The combination of stopper and it can improve machining accuracy and efficiency, and is suitable for making furniture, models, and DIY projects. When using the stoppers and T-shaped tracks, you need to pay attention to issues such as cooperative use, adjustment of position and degree of fixation, care and maintenance, in order to achieve the best results. Although the cost of T-slot miter rail jig and the is higher, its advantages are obvious for machining projects that require high precision and high efficiency.