Sheet metal processing is a method widely used in manufacturing and processing industries, where positioning and fixing are one of the key factors for processing accuracy and efficiency. In sheet metal processing, T Track Stopper, a small but practical positioning device, has become a very important tool.

What is T Track Stopper?

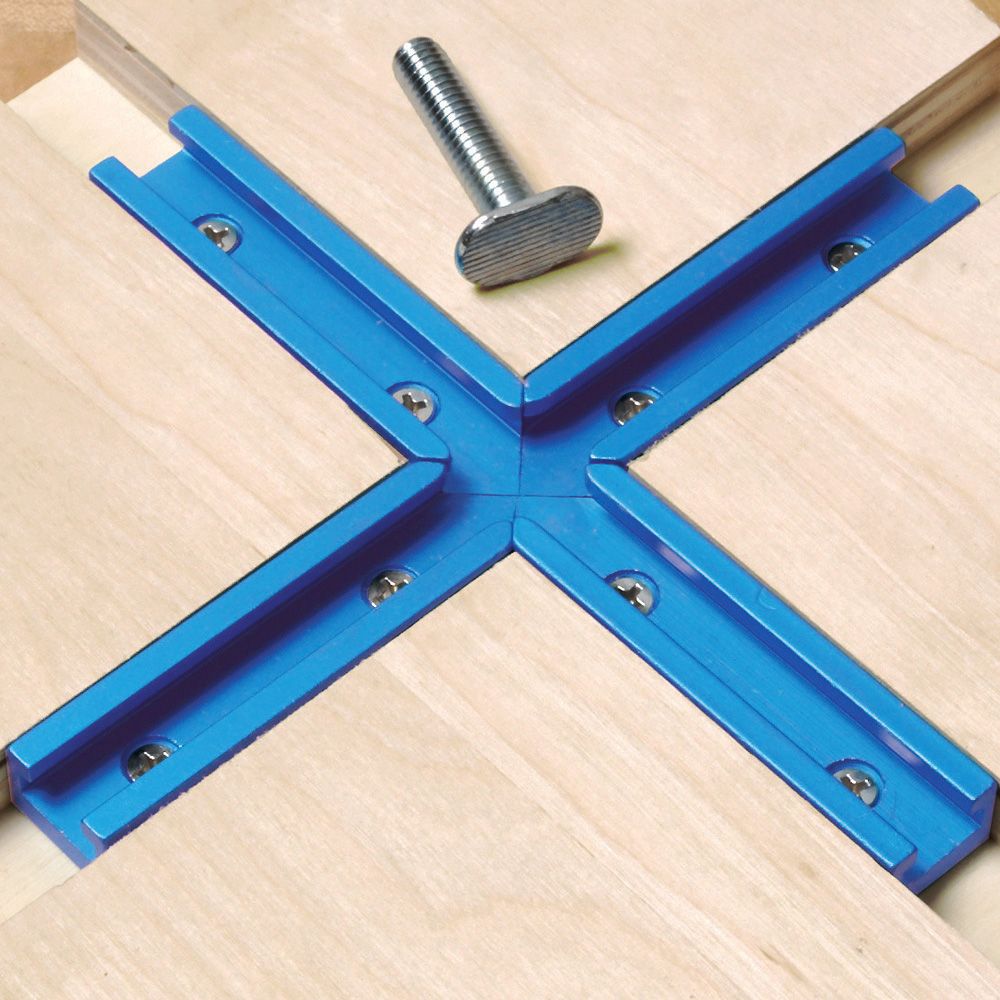

T-slot miter rail jig is a positioning device for T-track, which improves machining accuracy and efficiency by fixing and positioning items. It usually consists of stoppers and T-track fittings that keep items in place and secure during processing.

The application of T Track Stopper is very wide

In sheet metal processing, T Track Stopper is widely used. It can be used in various processing scenarios, such as sheet metal cutting, bending, punching, etc., and is especially useful for workpieces that require repeated processing. By using the T-slot miter rail jig, the processing personnel can fix the workpiece on the T-shaped track, accurately position and fix it, and avoid the deviation or falling off of the workpiece during the processing, thereby improving the processing accuracy and efficiency.

T Track Stopper also has the following advantages:

- Reliability and durability: T Track Stopper are usually made of materials such as metal and plastic, which has high strength and durability, and can withstand certain pressure and weight.

- Simple and easy to use: T-slot miter rail jig has a simple structure, easy to install and remove, convenient to store and carry, very convenient to use.

- Versatility: T Track Stopper can be used in various processing scenarios, such as sawing, drilling, planning, etc., and can accurately position and fix different types of workpieces.

When using The Stopper for sheet metal processing, it is necessary to select the appropriate specification and model according to the specific workpiece and processing project, and follow the instructions for proper installation and fixing. At the same time, you need to pay attention to safety issues to avoid hand injuries or equipment damage.

Design of the T Track Stopper

Adjustment screw: The adjustment screw is the part that adjusts the position and fixation of the stopper, and is usually made of metal. It needs to be designed with the size and shape of the stopper in mind, to be able to fit the stopper perfectly, and to adjust the position and fixation of the stopper by means of rotation.

In short, the design of T Track Stopper is carried out around the requirements and structure of T-shaped track. It needs to be designed with sufficient strength and stability taking into account the size and shape of the clamped item, while being able to fit perfectly with the T-track for precise positioning and fixing. In the process of using The Stopper, it is necessary to select the appropriate specification and model according to the specific processing project, and follow the instructions for proper installation and fixing.

Material of T track stopper

T Track Stopper is a positioning device for T-track, which can improve machining accuracy and efficiency by fixing and positioning items. A The Stopper usually consists of a stopper and a T-track fitting. Hope that helps you better understand its composition and performance.

Stoppers: Stoppers are usually made of aluminum alloy or stainless steel. These materials have excellent corrosion resistance and mechanical properties to ensure the stability and durability of the stopper.

In short, T-slot miter rail jig is a necessary positioning device for sheet metal processing, which can help processing personnel improve processing accuracy and efficiency. Its advantages lie in reliability and durability, and it is suitable for a variety of different processing scenarios. In sheet metal processing, the Stopper has become an indispensable tool, bringing a more efficient and precise processing experience to processing personnel.