T track stopper is a positioning device for T-shaped track, which can improve machining accuracy and efficiency by fixing and positioning workpieces. When choosing a T-slot miter rail jig that suits you, you need to consider a variety of factors, such as project type, workpiece size, processing requirements, etc. This article will introduce in detail how to choose a stopper that suits you, hoping to help you better understand and choose a stopper.

Learn about the types of T track stoppers

Before choosing a T track stopper, you need to understand the different types of the stoppers. Generally, T-slot miter rail jigs can be divided into the following categories:

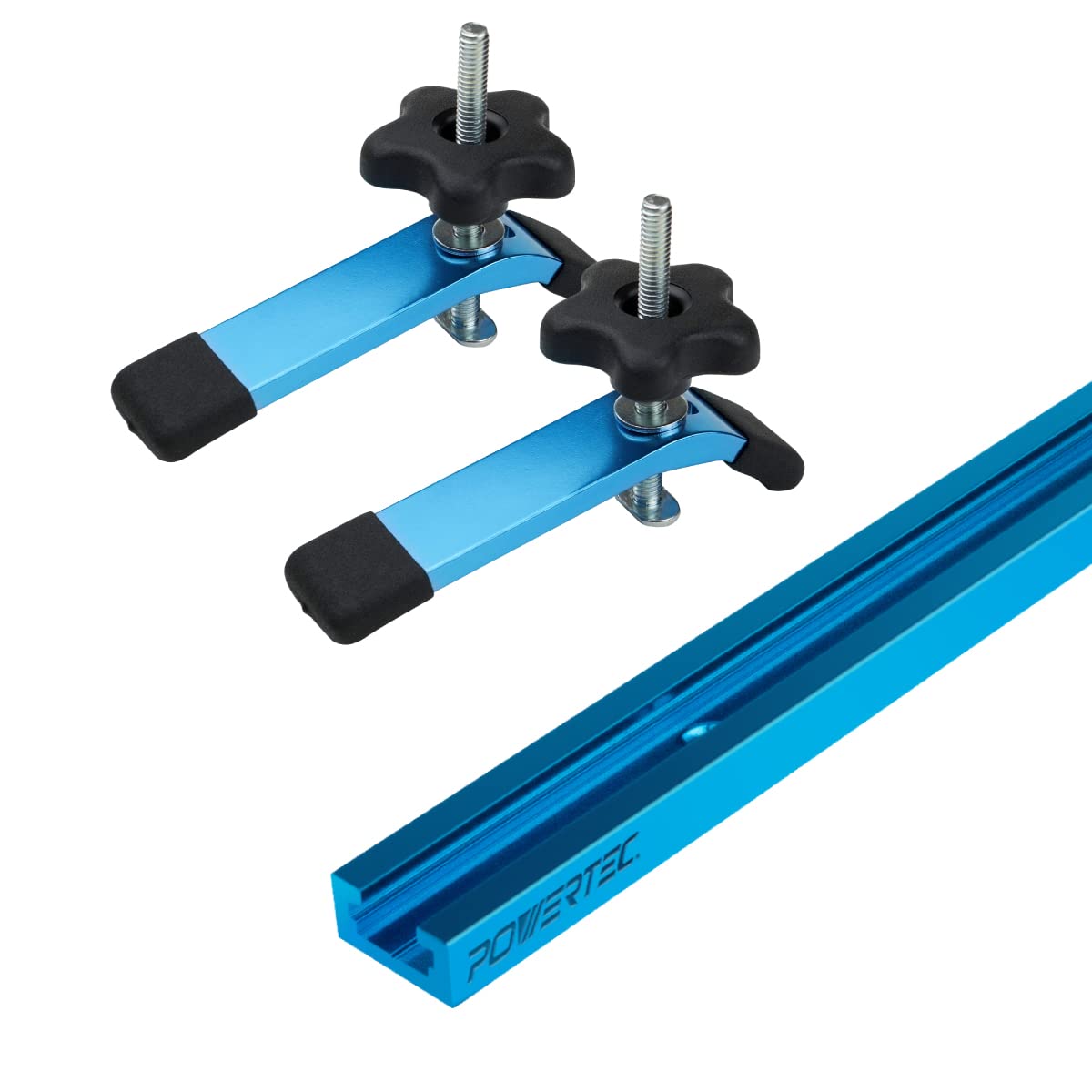

- Handle-type stopper: the handle-type the stopper controls the position and fixing degree of the workpiece through the handle, which is suitable for small workpieces and projects that require high machining accuracy.

- Sliding T-slot miter rail jig: the sliding the stopper controls the position and fixing degree of the workpiece through the slider, which is suitable for large workpieces and projects that require high processing efficiency.

- Self-locking T track stopper: the self-locking T-slot miter rail jig can control the position and fixing degree of the workpiece through the self-locking mechanism, and is suitable for various processing projects.

- Knob-type T track stopper: Knob-type the stopper can control the position and fixing degree of the workpiece through the knob, which is suitable for projects that require high processing accuracy and efficiency.

Consider project type and workpiece size

When choosing the T-slot miter rail jig that suits you, you need to consider the type of project and the size of the workpiece. For example, when making furniture, it is necessary to choose a suitable the stopper, which is suitable for large workpieces and projects that require high processing accuracy. When making models, you need to choose a stopper that is suitable for small workpieces and requires high machining accuracy.

For different workpiece sizes, different types of T-slot miter rail jigs also need to be selected. If the workpiece is small, you need to choose a handle type or self-locking the stopper to ensure machining accuracy. And if the workpiece is large, you need to choose a sliding or knob T track stopper to improve processing efficiency.

Consider processing needs

When choosing the T-slot miter rail jig that suits you, you also need to consider the processing requirements. For example, when drilling holes, it is necessary to choose a stopper that can accurately position and fix the workpiece to ensure that the drilling position is accurate.

When performing cutting and other processing, it is necessary to choose a stopper that can stably fix the workpiece to prevent the workpiece from sliding or tilting during processing. If multiple machining operations are required, you need to choose a T-slot miter rail jig that can quickly adjust the position and degree of fixation to improve machining efficiency.

Choose a reputable brand

When choosing a T track stopper, you also need to choose a reputable brand. By choosing a reputable brand, you can guarantee the quality and performance of the stopper, and avoid processing errors or accidents caused by the use of bad brand T-slot miter rail jigs.

Consider price and value for money

Finally, when choosing a stopper that suits you, you also need to consider price and cost performance. Price is an important factor for many users, so there is a tradeoff between price and performance. Choosing a stopper with reasonable price and high-cost performance can guarantee the processing quality and efficiency while saving costs.

Summarize

To choose the T-slot miter rail jig that suits you, you need to consider many factors, such as project type, workpiece size, processing requirements, brand reputation and price, etc. By understanding the types and characteristics of T track stoppers, combined with your own processing needs and budget, you can choose a stopper that suits you, so as to improve processing accuracy and efficiency.